Introduction

Wholesale distributors play a key role in the food system by purchasing, aggregating, and transporting large volumes of food and distributing it to their customers. Distributors typically sell to one or more of the following groups:

- Independent and chain restaurants

- Institutions such as schools, universities, and hospitals

- Retailers and grocery stores

- Corporate cafeterias

- Catering companies

By nature, distributors are the intermediate step in the supply chain between farmers and consumers, making a distributor a door through which farmers and producers can reach many customers and market opportunities. As a farmer or producer, selling product to a distributor offers a variety of benefits:

- You can sell larger volumes of product more efficiently than selling directly to consumers.

- You can reduce the time and resources spent on marketing directly to consumers to focus more on production.

- You can access different markets to increase sales volume and brand presence.

Although the benefits may be great, working with a distributor comes with challenges and requirements that are very different from those of direct marketing. On-farm operations, product packaging, marketing, pricing, food safety certifications, and logistics are all components that need to be carefully considered to create a successful relationship with a distributor.

In this publication, we provide guidance to farmers and producers who are considering selling to distributors. This information will be useful to owners of small and medium-sized farms who have not previously sold their products to a distributor.

Is Distribution Right for You and Your Business?

As a farmer trying to grow your business, you would like to pursue working with a distributor. Consider the following questions as they relate to your operation to make sure that this is the best market outlet to pursue.

- What is your goal for working with a food distributor? How does this fit into your current and future business plan?

- What market are you targeting by working through a distributor? Do you have any preexisting relationships with these types of customers?

- What products do you want to sell through a distributor? When are these products available throughout the year? Will you be able to supply the distributor with consistent product throughout your growing season?

- What is your current production capacity? Will you be able to expand production if demand increases?

- What is your current labor capacity for product, postharvest operations, sales, transportation, and other aspects of production?

- What is your current sales volume per week? How will your other customers be affected if you work with a distributor? If you plan to sell to more than one distributor, will you have enough product?

- What is the target sales volume you hope to achieve by selling through a distributor? Is this enough to cover the additional input costs?

- How will you get your product to the distributor?

Consider some key questions about your capacity before deciding whether distribution is right for your farm.

A Conversation Guide for Farmers and Distributors

Clear communication of expectations is crucial to begin a successful farmer-distributor relationship. Table 1 outlines distributors’ expectations in the form of questions, as well as questions that you should ask of a distributor. Review these questions to prepare for your first meeting with the distributor.

| Distributor Questions for Farmer | Farmer Questions for Distributor | Notes and Tips |

|---|---|---|

| What crops do you grow? Do you grow any special or unique varieties? | What products or crops are you seeking? Are there any products that you need more of or don’t have a local supplier for? | Distributors that source products from farms located outside the region may see your product as having a freshness and “local” advantage. If a distributor already has a reliable local supply for a specific product, the outlet may not need more from you. In this case, explore what other products you could supply and leverage your competitive advantage of being a “local” grower. If growing new or different products would require investment on your part (for example, new infrastructure such as a high tunnel or greenhouse), discuss your capacity to make this investment. |

| What is your annual product availability? For each crop, what date do you expect to begin harvesting and how long will the crop be available? | For each crop that you are interested in buying, how many weeks at a minimum do you need the product? | It is better to have produce continually available for at least several weeks. This allows the distributor to reduce shipments from nonlocal sources while your product is available. It also presents a longer time window during which the distributor can build demand for the product. This information should be readily available on your Annual Produce Availability Calendar (see Table 2). |

| Do you have the capacity to grade each crop you grow? Would you like to sell less than top-grade products if the option is available? | What are your receiving specifications for each product? If my product does not meet your receiving specs or expectations, how and when will you communicate this to me? | Note that receiving specs are different for each grade of product. |

| What type of packaging and pack sizes do you offer for each product? | Is there an opportunity to sell my product to markets that require different types of packaging, such as grocery stores? If so, how and when will this be communicated? | Distributors often supply grocery stores that may have specific packaging requirements, such as price look-up code (PLU) stickers, universal product code (UPC) labels, and bagged product, which can add to your packaging cost. |

| How is your product packaged for transport? Do you have the capacity to pack product on pallets? | Do you have any requirements for how pallets should be packed? | If packaging in these large quantities or the use of pallets is new for your operation, assess how this will fit into your budget and how it will affect your overall profitability. |

| Does your packaging and labeling meet label and traceability requirements? | Do you have any specific labeling and traceability requirements? | Labels must include the following information: name of product, name of farm and farm location or address, origin of product (if not produced by the packing farm), pack date, and lot number. This information can be on a sticker on the box or on custom printed boxes unique to your farm. |

| How do you set your free on board (FOB) prices? Do you prefer to sell by market price or would you prefer to lock in prices for the season? | What is your markup or margin? How will this affect the sales price of my product? | It is important to analyze pricing scenarios relative to sales volume so that you do not set prices too low, causing you to lose money, or too high, making your product cost prohibitive for potential customers. When setting prices, be mindful of market pricing, distributor markup, and added costs for transportation. Note that the distributor’s markups and margins differ by customer. Setting your price too low, to build demand for your product, is not recommended. This sets distributor expectations that you will not be able to meet in the long term. |

| Is your farm GAP (good agricultural practices) certified? If not, are you planning on getting GAP certified? | What are your food safety certification requirements? Do you have any other food safety requirements other than GAP? | Almost all distributors require GAP certification. If you are not GAP certified or don’t plan to get certified, working with a distributor may not be an option for your business. Be sure that you have a clear understanding of the different food safety certifications and audits you need for your specific operation and business model. Cooperative Extension can be a great resource for more information and training. |

| What are your harvest and postharvest practices? Do you have a wash-and-pack facility, or do you field pack? What is your cold chain capacity, including postharvest cooling, cold storage, and refrigerated transportation? | What are your acceptable temperature ranges when receiving produce? | Quickly removing field heat and maintaining the cold chain directly contribute to shelf life and quality of product. Product may be stored in a distributor's warehouse for up to a week before delivery to the customer, so it is important that your product be handled in a way that maintains quality from the time of harvest. Harvesting in the early morning decreases the risk of damaging the crop with heat. |

| Do you have cold transportation such as a refrigerated truck or trailer? | Can you pick up an order from my farm? | When the quality assurance (QA) team takes the temperature of your product, they will cut an item open and use a temperature probe to measure the core temperature. Cooling product only for surface temperature will not pass QA inspection. |

| What is your production schedule and order lead time on a weekly basis? | What is your typical order schedule on a weekly basis? | For more information about a distributor’s order timeline, see "The Distributor's Planning Timeline." |

| Do you send out a weekly availability list via email or text to your customers? | What is the best day of the week and time for me to send my availability list to you? What additional information would you like to see on the availability list? | Consistently sending an availability list every week is a very important part of your communication with the distributor (Table 3). This list provides the buyer with all the information needed to make ordering decisions and prepare the sales team to sell your product. |

| Who is running sales for your farm or operation? | Who from your team will be placing orders? | If you, the farmer, will not be coordinating sales for your operation, be sure to include that member of your staff in this conversation with the distributor. Help your staff and the distributor figure out the best way to communicate with one another. |

| Do you have product liability insurance? | How much product liability insurance does the distributor require? | Usually distributors will ask for a COI (certificate of insurance). COIs are sent from your insurance agency directly to the distributor via fax, email, or postal mail. COIs need to be renewed annually. |

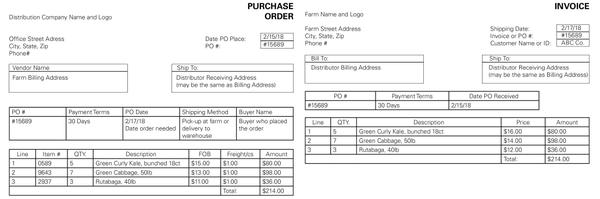

| Do you have the ability to invoice? Can you receive purchase orders via email? | How would you like me to invoice you? What are your payment terms? | Distributors require that you supply an invoice with every order via email before your product is delivered or as a hard copy upon delivery. Neglecting to send an invoice will result in delays in the warehouse and in receiving your payment, and could damage your relationship with the buyer. (See Figure 1 for a sample invoice and purchase order.) |

| Do you have any marketing materials or existing marketing strategies that could help us build a market for your product? | What are some ways that I can help to build a market for my product? Do you plan to send samples to customers? | See "Helping the Sales Team" for more information about how to prepare and collaborate with the sales team. |

The Distributor's Planning Timeline

You may be wondering how distributors decide how much product to order or how they communicate with their customers. It may seem that the buyers are very fast-paced and make decisions quickly, which is true. But their decisions are the result of considering many different factors: sales history, expected sales, current inventory, incoming product volume, product quality, transportation, seasonality of product, and how easy it is to work with each supplier. While buyers are making ordering decisions for the week, they are also looking two to three weeks ahead. Additionally, large food service customers, such as schools and universities, plan their menus months in advance. For example, universities have their fall menus and purchasing volumes planned by February to March, five months before they begin purchasing.

What does this mean for you as a farmer?

This means that you need to plan and communicate proactively. During the season, communicate upcoming availability with your regular buyers two to three weeks before harvest rather than notifying the buyer the week of harvest. This is not a binding order, but more of an update that allows the buyer to start adjusting their orders and depleting inventory in preparation for your product. In the long term, provide the buyer with your harvest calendar for the upcoming year so they can build you into their sourcing plans, especially for the larger food service accounts that plan menus months in advance.

The key is to be proactive and think ahead. Of course, plans change due to weather and other factors. But creating a plan, communicating with the distributor, and providing updates to the distributor allows them to factor your product into their decision-making and select your local product over product from across the country when they must make quick decisions.

Communicate upcoming product availability to your regular buyers at least two to three weeks before harvest.

Making Initial Contact

After examining your own goals and understanding what a distributor would expect from you as a vendor, you may have decided that working with a distributor is the right decision for you and your business. In this section, we describe how to connect with the buyers and decision-makers at the distributor.

When should you approach a distributor?

Typically, winter (December to February) is the best time to approach a distributor as they are planning with growers and customers for the upcoming season. They may be able to incorporate your products into their plan for the upcoming year, especially if you are prepared with your Annual Produce Availability Calendar (see Table 2). During the other months of the year, more crops are in season, so distributors are busy. You can still approach a distributor in the other months, but they may not have the time to work with you.

Who in the company should you talk to?

Ask to speak with the produce buyer or purchasing manager.

How can you make this connection?

- Visit the distributor’s warehouse in person.

- Email or call the produce buyer or purchasing manager.

- Attend grower-buyer networking events. Ask your local Cooperative Extension agent if these events are already being held, or could be held, in your area.

How should you prepare for your meeting with the buyers?

- Review Table 1. Guiding questions for beginning a farmer-distributor relationship.

- Bring your marketing materials and communication tools, samples or photos of your packed and unpacked product, and photos of your operation.

- Have several business or customer references for the distributor to contact, in case the distributor asks for references. Evidence that you are already selling to a retailer or restaurant gives the buyer confidence in your operation.

Onboarding Process

The distributor has offered to bring you on as a vendor, and you have accepted! The next step is the onboarding process to establish you and your business as an official vendor for the distributor.

Navigating paperwork

The onboarding process typically requires you to provide several documents before any transactions with the distributor can officially take place. Listed below are several documents you should have either printed out or prepared to upload to the distributor's database:

- New Vendor Set-Up Form (request from the distributor)

- Hold-Harmless Agreement (request from the distributor)

- Farm bio with photo

- Certificate of Liability Insurance with distributor listed as "Additionally Insured" and a possible Waiver of Subrogation

- GAP and Food Safety Modernization Act (FSMA) Certificates (These may need to be uploaded into Azzule, a food safety database.)

Helping the sales team market and sell your product

Work with your buyer to coordinate a meeting or phone call with the sales and marketing team. This is an opportunity to introduce yourself and your product to the people who will be selling your product, so they can communicate that information to their customers. Listed below are several ways that you can assist the team in their sales efforts:

- Compile a marketing packet with your marketing and communication tools. This can be digital or in print so that the sales team can send these materials to their customers. These materials can be used as a quick reference for the procurement and sales teams as well.

- Offer farm tours for the distributor’s staff or customers.

- Create and promote a social media presence so customers can engage with you and your farm directly. See more in the "Marketing and Communication Tools" section of this publication.

- Develop a plan to send out samples to customers, especially for specialty products. Customer samples are usually full cases of product so the customer can see your product quality and packaging. As the producer, you will be responsible for supplying samples, so it is important to determine how many and when samples will be sent out and if you need to send additional marketing materials. Be sure to follow up with procurement or the sales team for feedback one to two weeks after the samples have been sent.

Work with the sales team to provide high-quality samples and farm information to potential customers.

Preparing Your First Order

A successful first order requires a great deal of planning, attention to detail, and communication. This order also sets the precedent for your relationship with the distributor. Be sure that you are completely clear on how and when to communicate, with whom, and what to do if there is a last-minute problem. Communication is the key to establishing and maintaining a successful relationship!

Establish a detailed order schedule and a product communication plan

Work with the buyer to agree on a weekly schedule that works for both of you. This level of detail puts you and the buyer on the same schedule, so you can both plan your ordering and operations accordingly.

- This plan should incorporate when you send your weekly availability list (Table 3), required lead times for orders, order cut-off time, order confirmation deadline, and pick-up and delivery time windows.

- Establish how you will communicate: email, phone call, or text. Buyers may send you a purchase order via email.

- As previously discussed, it is helpful to give the distributor a two-to-three-week notice of new product coming on. Put your extended availability (two to three weeks out) on your weekly availability list to help buyers prep their sales team, adjust their procurement from other sources, and prepare the marketing for this product.

Transportation protocol: Delivery to warehouse

Each warehouse operates differently with various procedures and expectations. Make sure you have a clear understanding of the operations when you drop off product to avoid unnecessary wait time, food safety issues, or protocol breaches. Prior to your first delivery, make sure you have answers to the following questions:

- Where is the warehouse or delivery point? Are there any maps or photos that you or your driver can use?

- Who is responsible for unloading product from the truck? You or the warehouse staff?

- What is the delivery time window? Do you need an appointment for delivery?

- Who is on the receiving and QA team, and what are their procedures for determining quality and food safety? Find out the names of the receiver and people on the QA team so that you can greet them personally. You may be required to wait while the QA team completes their inspection of the order

- What is the dress code? Will you need any personal safety gear?

- Will the warehouse let you borrow their pallet jack to unload?

- How would the distributor like to be billed for freight on the invoice?

- An invoice is ALWAYS required upon each delivery or emailed ahead of time. Make sure the invoice and purchase order match in quantity, price, and date.

Effective communication between you and the distributor is the key to a successful relationship.

Transportation protocol: Pick-up at your operation

If the distributor will be picking up the order from your operation, use the following information to guide your communication with the buyer and the driver.

- Provide clear, written directions as well as a map or photos of your operation so the driver can find the correct location. Distributors will send either refrigerated box trucks or tractor trailers. Alert the buyer if your facility can’t accommodate certain truck sizes.

- You or someone from your staff must be available when the driver arrives to help them load the order. Drivers are on a very tight schedule due to driver Department of Transportation (DOT) rules and are limited to 30 minutes maximum per stop. Any unnecessary wait times or miscommunication could be detrimental to your relationship with the distributor.

- Distributors usually cannot give you a specific estimated time of arrival. Usually they will give you a four-hour window.

- It may be beneficial for you to exchange contact information with the driver, so you can contact each other directly, if need be.

If the distributor will pick up your product, make sure it is packaged and ready for a driver on a tight schedule

What happens if I cannot fulfill an order?

If you have a shortage or cannot fulfill an order after the order is placed, call the buyer as soon as possible and explain the situation. It may be possible to reschedule transportation or do a second delivery later in the week. Proactive communication is crucial to the success of this relationship.

What happens if my product gets rejected?

Product can be rejected for several reasons: product quality, product temperature above or below threshold, product grade, damaged packaging, or an incorrect order. If your product is rejected, be sure to ask why, and request a photo, if desired. Also, be proactive and meet with the QA team before your first delivery. Additionally, the distributor will not pay for the product, so you will need to decide what happens to it. You have two options:

- You can pick-up the product and take it back into your inventory.

- The distributor can get rid of the product by donating or disposing of it—there may be a charge to the grower for this.

If product is rejected, find out why and request a photo.

Marketing and Communication Tools

As discussed throughout this publication, marketing and communication are crucial to starting and building a successful relationship with a distributor. Listed below are several tools you can create to assist in your communication with the distributor and increase your market presence.

Annual produce availability calendar

Description: This calendar displays a timeline for all the crops you grow in a year or a season and when they will be harvested and available for purchase (Table 2).

Function: This document provides a full picture of crop availability throughout the year. During the season, this information allows the buyer to plan purchases two to three weeks before your harvest is available. During the winter months, this allows buyers and sales to plan menus with institutional customers who plan menus four to seven months before they begin purchasing product. Provide a hard copy of this calendar to the buyer, and send updates attached to your weekly availability list (Table 3).

Weekly availability list

Description: This document provides a list of products available for purchase for the upcoming week (Table 3). This list should include product name, pack sizes available, grade, and price. If possible, you should also add extended availability for product that will be available in the coming two to three weeks to notify the buyer of any new products that will be coming in. Also add photos of harvested product or product in the field. Having a nice looking and informative availability list will set you apart from the dozens of other lists the buyer may receive.

Function: This list provides the buyer with all the necessary information from which they will place their order. Your availability list should be emailed, called in, or texted to your buyer by the agreed upon time every week.

Available packaging sheet

Description: This document lists and describes available packaging options, including wholesale packaging, retail packaging, and labels.

Function: This list shows the buyer the different options for product packaging, which can help the buyer to match your product to the appropriate customers. It also helps to answer any questions about your labels or farm-specific packaging. Provide this at the beginning of the relationship and throughout the crop planning process.

Farm bio and web presence

Description: This document can be a flyer, brochure, or one-pager that tells the story of your farm, includes photos of the farm, describes your farming practices, and includes links to your website and Facebook or Instagram pages. Having social media and a web presence are vitally important for customers to learn more about your farm. The farm bio and your web presence are great opportunities to build your brand, cross-brand with customers, and educate people about your work on your farm. Having a media presence and following also makes you more attractive to potential wholesale buyers.

Function: To provide a brief overview of your farm for the sales and marketing teams. Some distributors help with marketing, so ask about any marketing that they provide. Nevertheless, it is helpful to have language and photos or video prepared for the distributor.

| Item | Acceptable Temperature Range (°F) |

|---|---|

| Apples | 33 – 38 |

| Asparagus | 33 – 38 |

| Beans, green/snap | 44 – 47 |

| Beans, Lima | 37 – 41 |

| Beets | 32 – 38 |

| Blackberries | 32 – 38 |

| Blueberries | 32 – 38 |

| Broccoli | 32 – 38 |

| Brussels Sprouts | 32 – 38 |

| Cabbage | 32 – 38 |

| Cantaloupe | 35 – 40 |

| Carrots | 32 – 38 |

| Cauliflower | 32 – 38 |

| Celery | 33 – 38 |

| Cherries | 32 – 38 |

| Corn | 32 – 38 |

| Cucumbers | 45 – 50 |

| Eggplant | 44 – 54 |

| Greens (Collards, Kale) | 32 – 38 |

| Herbs (Basil, Oregano) | 48 – 55 |

| Herbs (most types) | 38 – 42 |

| Honeydew | 49 – 55 |

| Leeks | 32 – 38 |

| Lettuce | 34 – 38 |

| Melons (whole) | 44 – 47 |

| Mushrooms (most varieties) | 33 – 38 |

| Nectarines | 32 – 38 |

| Okra | 44 – 47 |

| Onions, bulb | 44 – 47 |

| Onions, green | 32 – 38 |

| Peaches, ripe | 32 – 38 |

| Peppers, Bell | 44 – 55 |

| Potatoes | 45 – 50 |

| Pumpkins | 50 – 60 |

| Radishes | 32 – 38 |

| Raspberries | 32 – 38 |

| Romaine | 32 – 38 |

| Rutabagas | 32 – 38 |

| Salad Mixes | 32 – 38 |

| Spinach | 32 – 38 |

| Squash, hard | 50 – 55 |

| Squash, soft | 41 – 50 |

| Strawberries | 32 – 38 |

| Sweet Potatoes | 49 – 55 |

| Tomatoes, mature green | 49 – 55 |

| Turnips | 32 – 38 |

| Watermelon | 49 – 55 |

Resources

Market channel self-assessment

Market Channel Selection Tool. East Lansing, MI: Michigan State University Center for Regional Food Systems.

Packing and grading

Wholesale and Retail Product Specifications Guide. Raleigh, NC: Center for Environmental Farming Systems (CEFS), North Carolina Growing Together (NCGT).

Tips for Produce Growers Marketing Fresh Produce to Retail Grocers: Understanding PLU and UPC Codes (LF-002). Raleigh, NC: NC State Extension.

Wholesale Success: A Farmer’s Guide to Food Safety, Selling, Postharvest Handling, and Packing Produce (5th Ed.). Chicago, IL: Family Farmed.

Packaging Requirements for Fresh Fruits and Vegetables (AG-414-08). Raleigh, NC: NC State Extension.

Farm to distributor

Estimated Rows and Acres of Production per Case and Pallet at Wholesale, Select Crops. Raleigh, NC: CEFS, NCGT.

On-Farm Infrastructure Toolkit. Raleigh, NC: Carolina Farm Stewardship Association (CFSA) and CEFS, NCGT.

Process Walkthrough at a Regional Produce Distributor. Raleigh, NC: CEFS, NCGT.

Acknowledgement

This material is based upon work that is supported by the National Institute of Food and Agriculture, United States Department of Agriculture, under award number 2013-68004-20363. Any opinions, findings, recommendations, or conclusions expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.

Publication date: Aug. 13, 2018

Revised: June 15, 2023

LF-016

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.