Phosphorus in North Carolina Soils

Phosphorus (P) is the second most important nutrient in crop production but is often found in relatively low amounts in native soils. Decades of fertilizer application have led to P enrichment of most agricultural soils in North Carolina. Excess soil P that leaves agricultural fields via runoff and drainage can cause algal blooms that lead to impaired drinking water quality and can limit recreational activities. Maintaining adequate soil P levels for crop growth and limiting accumulation of P can reduce P runoff, save money, and protect the environment.

Soil testing is the only way to determine the levels of plant-available P in the soil. In fiscal years 2016, 2017, and 2018, the Agronomic Division of the North Carolina Department of Agriculture & Consumer Services (NCDA&CS) found that more than 50% of statewide soil samples tested very high in soil test P (Table 1). Soil test P levels are reported as indices by NCDA&CS after analysis using Mehlich-3 soil test extractant. The P index scale ranges from 0 to greater than 100, as noted in Table 1, and no yield response is expected for soils testing high or very high. Therefore, the application of phosphate fertilizers would not increase yields in 84% of the fields tested in the fiscal years 2016, 2017, and 2018 by the NCDA&CS soil test laboratory.

| Soil Test P Level | Soil Test P Index | Percent of NC Soil Samples (statewide) |

| Very high* | >100 | 50.6% |

| High* | 51 – 100 | 33.6% |

| Medium | 26 – 50 | 12.4% |

| Low | 11 – 25 | 2.7% |

| Very low | 0 – 10 | 0.7% |

| *No yield response is expected for soils testing as high and very high based on North Carolina fertilizer recommendations. | ||

Starter P Fertilizers

Starter fertilizer is a small amount of nutrients placed close to the seed at planting. Because the nutrients are placed near the seed, they are more accessible to a young root system. When weather conditions slow the growth of young roots, it can be an advantage to have a small amount of readily available nutrient close to the roots, especially for nutrients with limited soil mobility such as P. In North Carolina, starter fertilizer could provide some advantage when corn is planted early and cold soil temperatures may slow initial root growth. Consequently, it is not expected that starter phosphorus fertilizer will have any benefit in late spring, early summer, or when soil temperatures are warmer. Research has shown that starter nitrogen (N) is more important in corn production than starter phosphorus (Cahill et al. 2008).

The principal effect of starter P is a more rapid early-season growth, but it often does not translate into higher yields, and any small advantage can vanish during the crop season. Other factors may influence corn response to starter fertilizers, including the tillage method, soil type, soil fertility status, and yield potential. Conditions that limit growth or yield may also affect plant responses to starter fertilizers. Poor stands, insect or nematode damage, or drought can negate the effects of starter fertilizers.

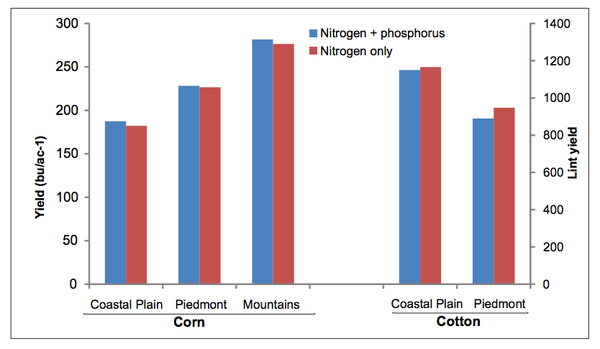

Starter P fertilizer is traditionally used in crop production in North Carolina. Often the rate of starter P is not based on soil test P recommendations. Fifty-one trials in North Carolina’s coastal plain, piedmont, and mountains investigated whether using starter P fertilizer would affect the growth of corn and cotton on soils having very high soil test P and some having high soil test P. Treatments were starter N and P (using DAP as starter) and starter N only. Significant treatment differences were not observed for corn or cotton yields (Cahill et al. 2008) (Figure 1). The use of only starter N is typically more cost effective than using both N and P starter fertilizers. Starter P fertilizer generally was not effective on mineral soils in North Carolina fields with high or very high soil test P values; this clearly indicates there is enough P in the soil close to the seeds, and it does not make sense to apply any additional, unnecessary P to soils already high in P. Not applying P fertilizer on soils with high or very high soil test P would save producers money, reduce soil test P levels in time, and reduce environmental consequences from agricultural fields.

Starter P Fertilizer Placement

An important factor affecting starter P success is fertilizer placement. Since the objective of starter P fertilizer is to deliver the nutrient that has limited mobility to the root system, the distance between the seed and the nutrient is critical: too close, and the fertilizer will burn the seed; too far, and quick access by young roots will be limited. Several placement options exist for starter P fertilizer.

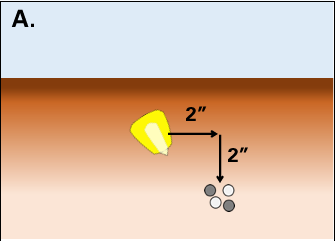

Two-by-two placement is the most common starter placement: 2 inches to the side of and 2 inches below the corn kernel at planting (Figure 2A). This precision placement method, called 2 × 2 placement, requires specialized equipment usually consisting of reverse knives, double-disk openers, or coulters with drop tubing behind them. Each equipment type has advantages depending on the tillage system used (such as no-till or conventional). All 2 × 2 placement units should be mounted in a manner that will allow them to “float” with the planter. Planter bar and row unit spacers often make it difficult to install additional fertilizer attachments. That’s why many users place fertilizer attachments on forward-mounted tool bars. Forward mounting of starter fertilizer equipment, however, makes placement less precise on rough or rolling ground. These mechanical constraints and the expense of application equipment for placement have prompted researchers and producers to try the alternative placement methods described next.

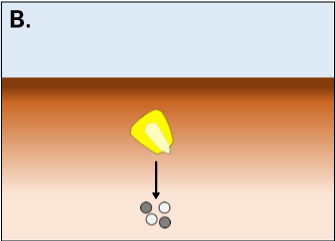

Below-seed placement (Figure 2B) is suited for in-row subsoiling units. When liquid fertilizer materials are used, a drop nozzle or stainless steel tube can be attached to the subsoil shank with adjustable locking collars that allow fixed placement at any depth below the seed. During application, care should be taken to prevent the liquid fertilizers from adhering to the subsoiler shank. When such adherence occurs, the liquid starter drips down to the subsoiler shoes and is unavailable for early plant growth. Splatter shields can be welded at specified depths on the subsoiler, or a K-3 or K-5 flood nozzle can be mounted on the end of the drop nozzle with a 45-degree elbow directing the nozzle spray away from the subsoiler shank. Either method will prevent the fluid from dripping down to the subsoiler shoe. When granular fertilizers are used, materials should be allowed to fall freely into the subsoil rack from a height of 6 inches above the soil surface. Soil movement prevents granular materials from dropping all the way down to the subsoiler shoe. Below-seed placement is not as precise as a floating 2 × 2 placement or any surface placement because of draft bar movement.

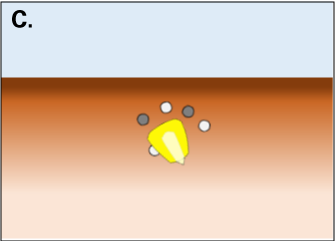

In-furrow or “pop-up” placement (Figure 2C) of fertilizer with the seed requires simple equipment but may result in fertilizer injury. Fertilizers applied with this technique are commonly referred to as pop-up fertilizers. Pop-up fertilization in North Carolina should be applied at lower rates than 2 × 2 placement to reduce salt damage risk.

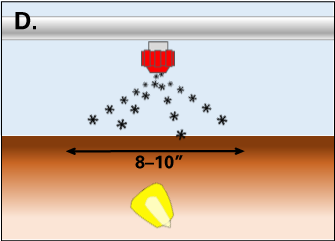

Over-the-row banding (Figure 2D) may be more effective on sandy soils than on clay soils. Placement can be accomplished with conventional banding equipment. Starter fertilizer solutions may be sprayed over the seed furrow with nozzles placed behind the press wheel. Band widths of 6 to 12 inches can be obtained with nozzle height adjustments. This method requires less fertilizer than broadcast and places nutrients near roots where plants can use them more readily.

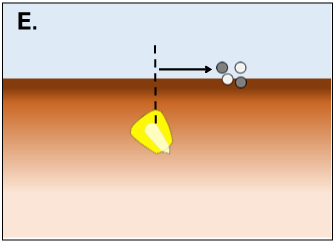

Surface dribble (Figure 2E) may also be most effective on sandy soils. It can be set up with conventional banding equipment oriented to deliver a stream of starter fertilizer that is offset 2 inches on one or both sides of the seed furrow. Most often, an appropriately sized orifice is used to meter the starter fertilizer. If a fan nozzle is used, it must be turned parallel to the seed furrow direction.

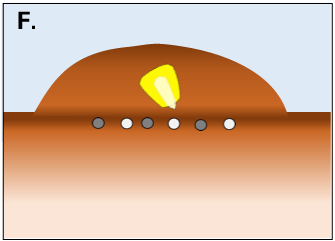

Under-the-row banding (Figure 2F) is done with a T-shaped PVC manifold with orifices extending along a specified band width and mounted on a disk bedder. Precision with this method of starter fertilizer placement depends on the bedder’s action. Abrasive action of soil during bedding may reduce the life of the PVC manifold. Bands should be placed at least 2 inches away from the seed to prevent damage.

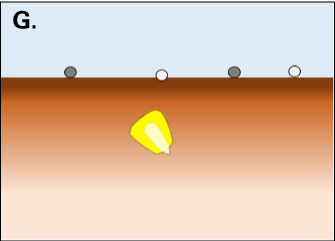

Broadcast (Figure 2G) is a uniform distribution of fertilizer or lime on the soil surface. Nutrients may be placed in the field as topdressing or incorporated with a moldboard plow, chisel plow, or disker. Although this type of application is easy to apply and does not require expensive equipment, it can result in N losses and more fertilizer available for weeds, and it requires water to move the N to plant roots if left on the surface.

Plant Response to Placement Methods

Plant growth and nutrient uptake can be influenced by placement method. In general, placing the fertilizer close to the seed provides the greatest plant response. It is also important to ensure that application equipment is aligned uniformly so that starter fertilizers are placed the same distance from each row. Large plant-growth variations between rows may be observed with placements differing by only 1⁄2 inch.

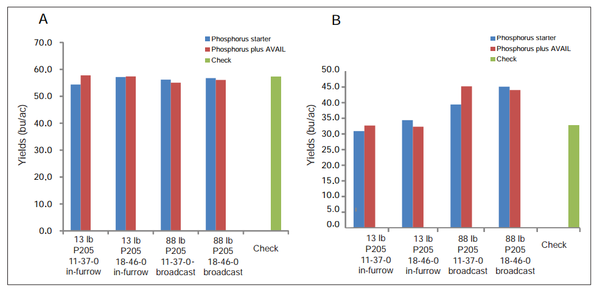

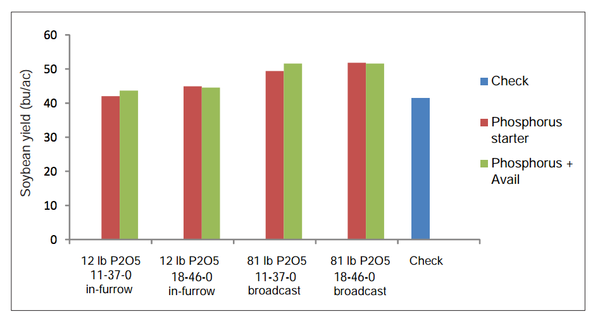

We investigated whether fertilizer placement affected plant growth in North Carolina. Results from a one-year soybean study (2009) in Bertie County (Figure 3A) showed no clear advantage from fertilizer rate, placement, or source (Dunphy et al. 2009b). The yields were similar in the control without fertilizers and in the fertilized treatments. Results at the second location in the study, Forsyth County (Figure 3B), indicated that treatments with higher rates of broadcast fertilizer yielded more than lower rates in-furrow, regardless of fertilizer source (Dunphy et al. 2009a). Meanwhile, the in-furrow fertilization yield was similar to the control treatment without fertilization. Similar on-farm studies were conducted on soybeans grown on a Craven fine sandy loam soil in Beaufort County in 2009 (Figure 4). The treatments also included a fertilizer enhancer (Avail®). The soil test P index at the study site was 25 (low). All treatments had greater yields than the untreated control where no P was applied, confirming the responsiveness of the site to P application (Ambrose 2009b). As Figure 4 shows, broadcast application at a high P rate produced higher yields than in-furrow at a lower P rate. The enhancer did not increase soybean yields over starter P alone, regardless of fertilizer rate, source, or placement.

P Fertilizer Enhancers

On soils that are likely to benefit from starter P application (soils with very low, low, and medium soil test P or very high or low soil pH), P fixation can be a problem. Applied P fertilizer can be rapidly fixed in soils, resulting in substantial amounts of the applied P becoming unavailable to plants. Fertilizer additives have been developed with the goal of reducing phosphate fixation in soils. Because these products do not supply nutrients, they cannot be evaluated based on nutrient content. Examples include water soluble humic and fulvic acid products, polyaspartic acid additives, and maleic-itaconic copolymer for P fertilizer enhancement. Manufacturers state that these products may increase soil cation exchange capacity and limit reactions that reduce P availability.

Calculations by North Carolina State University Soil Science faculty found that the increase in cation exchange capacity when using a humic acid or a polymer product is relatively small, only occurs in the fertilizer band zone, and will not affect subsequent crops (Crozier et al. 2009). Applying humic acid products at manufacturers’ recommended rates is also unlikely to change soil humate concentration.

AVAIL Fertilizer Enhancer

One specific maleic-itaconic copolymer product being marketed throughout the United States is AVAIL (Verdesian Life Sciences), a P fertilizer enhancer. According to the manufacturer, AVAIL is designed to reduce P fixation of applied P fertilizers by surrounding the fertilizer with a “shield” that blocks the bonds of attraction between P and chemical elements that tie up P in soil (typically calcium, magnesium, iron, aluminum, or a combination of these elements). The manufacturer does not link these claims to soils of any particular soil test P level. Doydora et al. (2017) proofed the concept that AVAIL can reduce P fixation in a lab study; however, researchers had to apply hundreds of times the recommended rate of the enhancer to observe some relief on phosphorus fixation.

More than 20 trials were conducted throughout North Carolina from 2007 to 2009 with the AVAIL enhancer. Starter P fertilizer sources with and without AVAIL were compared at various rates and using different application methods. These studies were conducted primarily on corn sites but also included cotton and soybean sites. Soils ranged from a very poorly drained, fine sandy loam to a well-drained silt loam. Soil test P on test sites ranged from low to very high. The conclusions from the 20 trials suggest that starter P fertilizer plus AVAIL enhancer does not significantly increase corn grain or cotton lint yields over starter P fertilizer alone (Ambrose 2009a; Braswell 2008; Cahill et al. 2008). When comparing application methods, AVAIL did not increase soybean yields regardless of method applied, and response to rates was generally not seen for any crop.

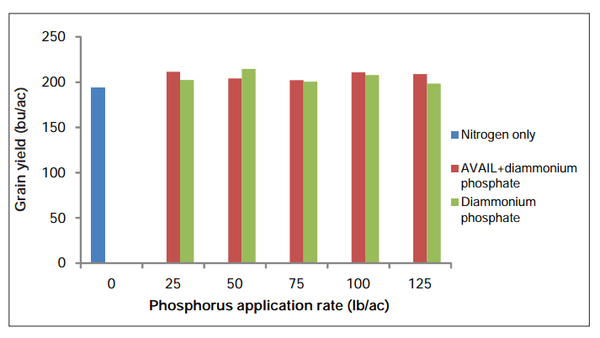

An example of the many trials in which we tested AVAIL was a two-year field trial with fertilizer treatments including AVAIL on low and medium soil test P soils in the North Carolina mountains. Corn yield, early season plant color, height, and tissue N or P did not respond to diammonium phosphate treated with AVAIL differently than untreated diammonium phosphate (Cahill et al. 2013). Yield did not respond to increasing P rates (Figure 5), indicating that these soils were able to supply adequate P to achieve maximum yields.

Summary

Eliminating starter P fertilizer applications on high and very high soil test P soils is both financially beneficial to producers and environmentally beneficial to our water resources. Recent research across the state on various soil types with different soil test P levels found few differences among plots fertilized with starter P and N fertilizer sources compared with N-only sources. P fertilizer does not appear to be necessary on mineral soils in North Carolina that test high or very high in soil test P. Starter P is still recommended on organic soils that test high. Starter P fertilizers can be applied several ways, depending on producer preference and mechanical equipment. On sites with relatively low soil test P, a 2 × 2 placement is recommended to reduce P fixation and provide more P to the crop. The use of enhancers should be carefully evaluated by the user, as multiple field studies across our state—on many different soil types, soil test P levels, and crops—show that the use of AVAIL fertilizer enhancer with P rarely increased yields.

References

Ambrose, G. 2009a. “2009 On-farm-test Report: Corn Preplant Fertilizer and At-planting Fertilizer Treatments with and without AVAIL.” Raleigh: NC State University. Unpublished.

Ambrose, G. 2009b. “2009 On-farm-test Report: Phosphorus and AVAIL Soybean Trial.” Raleigh: NC State University. Unpublished.

Braswell, S. 2008. “Nitrogen Efficiency Enhancement Studies.” Raleigh: NC State University, N.C. Cooperative Extension, Stanly County Extension Center. Unpublished.

Cahill, S., A. Johnson, D. Osmond, and D. Hardy. “Response of Corn and Cotton to Starter Phosphorus on Soils Testing Very High in Phosphorus.” Agronomy Journal 100, no. 1 (2008): 537–542.

Cahill, S., R. Gehl, D. Osmond, and D. Hardy. “Evaluation of an Organic Copolymer Fertilizer Additive on Phosphorus Starter Fertilizer Response by Corn.” Crop Management 12, no. 1 (2013).

Crozier, C., R. Gehl, and D. Osmond. “Evaluating Organic Soil Amendments and Fertilizer Enhancers.” Crops and Soils 42, no. 2 (2009): 19–22.

Doydora, S., D. Hesterberg, and W. Klysubun. “Phosphate Solubilization from Poorly Crystalline Iron and Aluminum Hydroxides by AVAIL Copolymer.” Soil Science Society of America Journal 81, no. 1 (2017): 20–28.

Dunphy, J., G. Ambrose, and M. Buffaloe. 2009a. “Beaufort County Phosphorus and AVAIL On-the-farm Test.” Raleigh: NC State University. Unpublished.

Dunphy, J., R. Rhodes, and M. Buffaloe. 2009b. “Bertie County Phosphorus and AVAIL On-the-farm Test.” Raleigh: NC State University. Unpublished.

Acknowledgments

This publication is a revision of an earlier version. The authors would like to thank S. Cahill, R. Gehl, and C. Crozier for their earlier contributions.

Publication date: July 1, 2020

AG-439-75

Recommendations for the use of agricultural chemicals are included in this publication as a convenience to the reader. The use of brand names and any mention or listing of commercial products or services in this publication does not imply endorsement by NC State University or N.C. A&T State University nor discrimination against similar products or services not mentioned. Individuals who use agricultural chemicals are responsible for ensuring that the intended use complies with current regulations and conforms to the product label. Be sure to obtain current information about usage regulations and examine a current product label before applying any chemical. For assistance, contact your local N.C. Cooperative Extension county center.

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.