Swine manure can be an excellent source of nutrients for crop production. The key to proper management is determining the nutrient content of the manure, the percentages of those nutrients that are available to the plant, and the nutrient requirements of the plant. Considered together, these three factors will help you apply the proper amount.

Operation Size

Any operations with 250 or more swine are subject to regulatory oversight through the North Carolina Department of Environmental Quality. These operations fall under the Swine General Permit and must have a Certified Animal Waste Management Plan (CAWMP) written by a state-approved Technical Specialist. CAWMPs outline land application fields needed to use all manure generated on the farm. The plan addresses crop rotations, realistic yields expected for manure-receiving crops, and the appropriate nitrogen application rates. The total crop acreage is a function of the number and types of animals as well as the manure treatment processes used on the farm.

Nutrient Content of the Manure

The average nutrient values for different swine manure systems are found on the Nutrient Management in North Carolina website. These values can be used as planning guidelines but should never be used for determining actual applications to receiving crops.

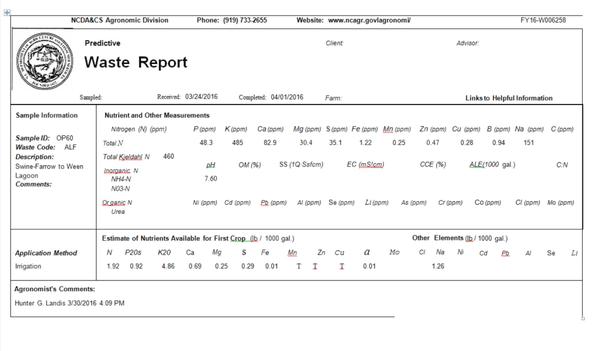

Because the nutrient content of swine manure varies among operations and over time, the manure must be analyzed before you apply it to the land. Waste samples can be analyzed for $8 through the North Carolina Department of Agriculture & Consumer Services (NCDA&CS) Agronomic Division’s Plant and Waste Analysis Lab. For more information, call (919) 733-2655 or visit the NCDA&CS website. Other qualified private laboratories are also available (fees vary). To maintain compliance with the state General Permit for swine waste application, you should base applications on waste samples collected within 60 days of application.

Samples collected for analysis should be representative of the pit or lagoon, combining samples from 10 to 12 locations at least 6 feet from the edge and 1 foot deep in the lagoon or pit. If the waste is to be applied as a slurry, the storage pit or basin should be agitated before sampling. Collect approximately ¾ of a pint of material in an expandable container, being sure to leave air space. Never send samples in a glass container. For more information on how to collect a representative sample, see NC State Extension publication AG-439-33, Waste Analysis SoilFacts.

Table 1 shows the average amounts of secondary nutrients and micronutrients present in swine manures. Zinc and copper levels can increase in soils to which swine manure has been applied. Give special attention to the concentration of these elements in both soil that is receiving manure and manure to be applied to fields. Elevated soil zinc or copper can cause plant toxicity, drastically reducing yield capabilities. Peanuts are especially susceptible and should never be planted in soil with a zinc-index above 500, with a cautionary level beginning at 300. The soil zinc-index and copper-index thresholds are 3,000, above which no further application of zinc or copper is allowed in accordance with the Swine General Permit.

| Manure Type | NCDA&CS Waste Code | Ca | Mg | S | Na | Fe | Mn | B | Zn | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| lb/1,000 gallons | ||||||||||

| Liquid slurry | LSS | 14.8 | 4.8 | 2.7 | 2.6 | 4.0 | 0.23 | 0.015 | 0.97 | 0.29 |

| Lagoon sludge | ASS | 21.1 | 9.0 | 5.0 | 3.7 | 4.1 | 0.36 | 0.0191 | 3.1 | 0.61 |

| lb/acre-inch | ||||||||||

| Lagoon liquid | ALS | 18.4 | 9.1 | 6.9 | 39.3 | 1.1 | 0.26 | 0.167 | 0.93 | 0.25 |

| Source: North Carolina Department of Agriculture & Consumer Services | ||||||||||

Nutrient Availabilities

The total nutrient content of the waste (either reported on the Nutrient Management in North Carolina website or on a manure analysis report) is not immediately available to the crops when the material is applied. Some elements are released when soil microorganisms decompose the organic matter. Other elements can combine with soil constituents and become unavailable for plants. Nitrogen may also be lost to the atmosphere through volatilization or denitrification, or leached through the soil into groundwater, depending on the application method and soil moisture levels.

Waste analysis reports from the NCDA&CS’s Agronomic Division (Figure 1) provide nutrient availabilities for the first crop. Therefore, no availability factor is needed; just use the amount of nutrients specified at the bottom of the report. Be aware that other laboratories may list total nitrogen and require adjustment using an availability coefficient.

The most recently applied waste is not the only source of nutrients. With the exception of nitrogen, updated soil tests are the best means of determining nutrient reserves from previous manure applications. Legume crops can also supply nitrogen (Table 2) to the next crop and must be factored into decisions about nitrogen application rates.

Application Rates

Land application rates of manure are generally determined by matching the available nitrogen or phosphorus content of the wastes to the nutrient requirements of the crops. In most cases, nitrogen needs will determine the application rate. Nitrogen recommendations for various crops are determined using the soil type and crop rotation. Use the Realistic Yield Expectation (RYE) website. To determine the RYE, select your county and the dominant soil type found in your field. Next, use the resulting table to find the RYE and Realistic Nitrogen Rate for your crop. Use the Realistic Nitrogen Rate coupled with your waste analysis to identify allowable nitrogen-based manure application rates. With feed and forage crops, excessive manure application can produce high nutrient concentrations in soils and plants, which can result in water quality impairment or reduce the yield and quality of crops.

If a swine facility is required to run the Phosphorus Loss Assessment Tool (PLAT), a rating of “high” would require phosphorus-based application rates. No further manure application is allowed with a rating of “very high.” NC State Extension publication AG-439-56, The North Carolina Phosphorus Loss Assessment Tool (PLAT) provides more information on facilities required to run PLAT. When running the PLAT analysis, conservation practices will affect the risk of phosphorus loss. These conservation methods include, but are not limited to, reduced tillage, riparian buffers, and controlled drainage. Leaching of phosphorus is limited in the piedmont and mountains of North Carolina and therefore should not contribute to groundwater contamination. Leaching has been known to occur, however, in sandy soils that have received high amounts of swine effluent in the past. Deep soil sampling may be required depending on the soil series and soil-test phosphorus level. Protocols for deep soil sampling can be found in NC State Extension publication AG-439-40, Deep Soil Sampling for Nutrient Management. For non-legume crops, phosphorus-based manure application will not supply adequate nitrogen to meet the RYE, requiring supplemental commercial fertilizer.

In addition to the supply of nutrients, proper soil pH is required to improve crop yields and ensure nutrient availability. The biological conversion of ammonium to nitrate is an acid-forming process that will continue to reduce soil pH unless you follow an adequate sampling and liming program, although often manures can increase the pH of soil.

A worksheet is provided in this publication to help you determine land application rates of swine effluent.

Timing of Manure Applications

Besides carefully calculating the application rate, you must also minimize the delay between applying the manure and planting the crop. Precise timing increases the amount of nitrogen the crop uses and can reduce the risk of nitrogen loss via leaching. On sandy-textured soils, apply manures at low rates throughout the growing season, wherever possible, to reduce nitrogen leaching. Apply manure only to an actively growing crop — within 30 days of planting or within 30 days of breaking dormancy.

Use caution when applying lagoon liquid through irrigation onto standing crops that are undergoing stresses, as the salt concentration can cause additional problems.

Manure Processing

You can modify the nutrient content of manure by introducing a processing system. Manure processing relies on chemical, biological, or mechanical steps to change the nutrient concentration and manure characteristics. Solid-liquid separation is the most common system. In this type of system, the manure is separated into two streams: (1) phosphorus-rich solid fraction and (2) liquid fraction rich in nitrogen and potassium. Manure can be separated using gravity, screens, mechanical presses, centrifuges, polymers, or a combination of these options. These technologies can help producers use manure more efficiently to meet the nutrient needs of different fields and crops.

Another manure processing option is anaerobic digestion, in which manure organics are converted into a gas fuel (biogas). While anaerobic digestion can reduce greenhouse gas emissions from the operation and generate income from biogas production, there is little impact on total phosphorus or potassium in the system. From a fertilizer value perspective, the byproduct of digestion (digestate) contains more plant-available nitrogen (PAN) than unprocessed manure — consider this when determining the timing of digestate application to crop fields.

Manure acidification is a treatment whereby acids are added to the manure to reduce ammonia losses through volatilization. As a result of this treatment, manure nitrogen concentration increases, which increases the PAN. While manure acidification has not been adopted in the United States, there could be opportunities for implementation in the future; you should monitor changes in nutrient concentrations when using this technique.

Regular sampling and analysis of processed manure are necessary to ensure application rates are aligned with the growing crop’s needs. Manure processing systems must be carefully selected and designed to meet the needs of the operation, while avoiding unnecessary costs and complications of managing two or more pools of manure.

Value of Manure

To compare the value of manure to commercial fertilizer, convert the manure nutrients to available nutrients by using their availability coefficients. In the following example, the amount of PAN, phosphorus (P2O5), and potassium (K2O) in each acre-inch of lagoon liquid is approximately 49, 38, and 225 pounds per acre, respectively. At 45 cents per pound of nitrogen, 60 cents per pound of phosphate, and 22 cents per pound of potash, the manure’s gross worth is (49 × $0.45) + (38 × $0.60) + (225 × $0.22) or $22.05 + $22.80 + $49.50 = $94.35 per acre for each inch of lagoon liquid.

The estimated value of the manure does not include labor, transportation, or equipment costs, or the value of any secondary nutrients or micronutrients available in the manure. In addition, the estimated value assumes that the soil test has indicated a need for each nutrient when many nutrients may not be needed, such as the ratio of nitrogen to potassium in the previous example calculating manure nutrient value. Using total nutrient value will generally result in overestimating the dollar value of the manure. Consider only necessary nutrients when assessing the financial value of the manure.

Acknowledgments

This publication is a revision of an earlier version. The authors would like to thank J. C. Barker, D. A. Crouse, J. W. Parker, C. M. Stanislaw, and J. P. Zublena for their earlier contributions. The authors wish to acknowledge the assistance and cooperation of the NCDA&CS Agronomic Division for the development of the database used in this publication.

Publication date: Oct. 9, 2019

AG-439-04

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.