Introduction

Weeds can severely impact crop yields and quality by competing with crops for vital resources such as nutrients, sunlight, moisture, and space (Steward et al., 2019). Organic farmers report that weeds are one of the primary causes of production losses, second only to weather-related losses (Walz, 2004).

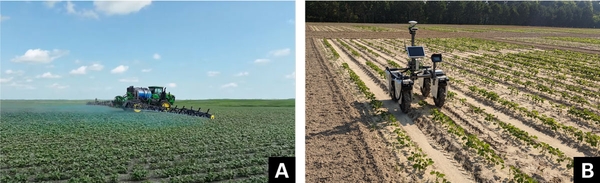

Robotic weeders are uncrewed vehicles designed to identify and remove weeds from crop fields with minimal human intervention. Robotic weeders encompass a range of automated systems designed for efficient weed management in agriculture. This includes large-scale solutions such as self-propelled sprayers equipped with sensor booms for precision weed control across extensive fields (Figure 1a). Smaller, more portable machinery systems are also part of this category, offering flexibility for varied farming environments (Figure 1b). These robotic weeders employ advanced technologies such as computer vision, AI, and mechanical tools to autonomously or semi-autonomously navigate through crops, identify weeds, and execute targeted removal. The overarching goals are to enhance weed control efficiency, minimize reliance on herbicides, and reduce the need for manual labor in agricultural operations.

The trend in row crops has been to adopt large equipment to increase field efficiency, but heavy equipment can contribute to soil compaction. Broadcast application of herbicides is expensive, especially as weed resistance to herbicides is increasing. Agricultural producers take multiple steps to responsibly apply herbicides, but there can be environmental concerns with these products and many consumers are actively seeking products that minimize or eliminate herbicides in agricultural goods. Robotic weeders are emerging as a tool in modern agriculture, offering innovative solutions to address the challenges of traditional weed control methods. These autonomous or remotely operated machines promise to provide needed options to the agricultural landscape by offering several advantages, including increased precision, efficiency, and sustainability.

Selective Robotic Weeding Enabled by AI and Robotics

Artificial intelligence (AI), the field focused on creating computer systems capable of emulating human intelligence for tasks like visual perception, speech recognition, and decision-making, has demonstrated potential in agricultural applications. Small-scale, portable robots coupled with vision-based, single plant detection and classification systems enabled by AI show great potential for use in sustainable weed control activities by targeting the growing point of small weeds. Selective weeding technologies can differentiate between weeds and crops based on computer vision and machine learning and enable targeted weed control. Small robotic weeders have some advantages due to precision in targeting weeds, minimal soil disruption, and affordability for smaller farms.

The engineering design of robotic weeders is a multifaceted task. These machines must be capable of managing different end-effectors—the specialized tools or attachments that are part of the robots and are responsible for performing weed removal—to tackle various weed species and different crop poses and growth stages. Different environmental conditions, terrains, and soil profiles must be considered during design to guarantee robotic weeders’ effectiveness and reliability.

Robotic weeders have four key technologies (Edan et al., 2023):

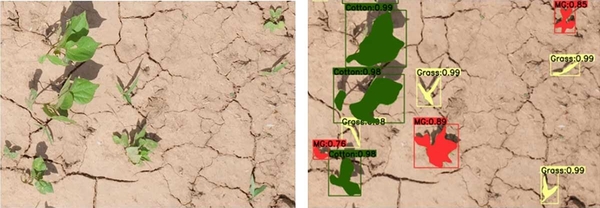

- Observation: Robotic weeders are equipped with advanced AI-enabled vision systems that employ cutting-edge sensing technologies to detect and identify weeds through visual intelligence. These systems can distinguish between crops and unwanted plants, ensuring accurate weed detection at pixel level (Figure 2).

- Action: The action component of robotic weeders is powered by versatile end-effectors with different types of weed control technologies (mechanical, thermal, chemical, and electrical). These specialized tools enable precise and effective weed removal. They can be designed to handle various weed species, crop growth stages, and plant architectures, providing efficient weed management.

- Guidance: The guidance system in robotic weeders includes self-navigation capabilities. These systems are designed for autonomous operation in the field. They consider a range of environmental conditions, terrains, soil profiles, and weather, ensuring the robotic weeder's adaptability and efficiency.

- Mapping: Enabled by global positioning system (GPS) and machine vision technologies, mapping functions aim to visualize and track the distribution of weeds across the entire field. Performing weed mapping before treatment application is necessary to assess weed distribution and identify the appearance of weed patches.

Previous research on weed removal using autonomous mobile robots has shown a robotic weeder that detects and selectively sprays the weeds with a small dose of herbicide can reduce the volume of required herbicides by 20 times compared to conventional spray systems and can reduce the use of herbicides by up to 95% (Zhang et al., 2022), making them an eco-friendly and sustainable solution for weed management.

As an example, Verdant Robotics has developed a robotic weeder, the Sharpshooter, for spot weeding. It is equipped with a computer system that identifies weeds. It sprays the detected weeds with a small dose of herbicide. According to the manufacturers of the Sharpshooter, their prototype can reduce inputs by 96% and decrease weeding costs by more than 50% compared to conventional methods.

Commercialization success has also been achieved using tractor-drawn cultivators and sprayers. The Robovator and the Steketee IC are vision-guided cultivation machines currently sold in the US that have proven useful for conditions in California lettuce production, where they reduced labor needs by 37% (Smith, 2016). A British company, Garford Farm Machinery, has developed a commercial vision-based tractor-drawn in-row weed cultivator called Robocrop and another version of the implement that uses a spot sprayer.

Benefits to Society

Robotic weeders offer farmers a cost-effective solution to address weed control challenges. Manual weeding can add more than 40.5 hours per acre of labor, and Singh et al. (2018) reported that farmers can spend up to $1,000 per acre on weed control. Previous research by Lowenberg-DeBoer et al. (2020) showed that farmers can reduce weeding costs by up to 50% by investing in a two-row (1.0 m) robotic weeder that costs $28,846 and is 80% efficient. Even if the farmer paid up to $43,108 for the robotic weeder, they would still be better off than with manual weeding (Lowenberg-DeBoer et al. 2020).

Small robotic weeders are more affordable for small-scale farms. For example, members of our team have built prototype sprayer systems (for example, as shown in Figure 1b) for around $5,000, and unit costs for a commercialized system would be lower.

Small robotic weeders present a promising option for weed control in agriculture compared to larger weeding machines for several compelling reasons:

- Their precision and selectivity in targeting weeds result in minimal crop damage.

- Lightweight and compact designs reduce soil disturbance and minimize soil compaction, preserving soil health.

- The units can be affordable, accessible, and suitable for small farms, ensuring cost-effectiveness in weed management.

- The capability to operate autonomously reduces labor costs and saves valuable time for farmers.

- Embracing renewable energy sources such as solar to power these units further reduces the environmental impact of weed control practices.

- The scalability of small robotic weeders allows them to be employed on both small and medium farms, offering versatility and a cost-effective solution to farmers seeking efficient and eco-friendly weed management practices.

Use in North Carolina

To harness the full potential of robotic weeding technology for North Carolina's agricultural sector, it is crucial to outline specific strategies that farmers can adopt. The introduction of robotic weeders can dramatically reduce the reliance on manual labor and herbicides, which is particularly beneficial given the labor shortages and rising costs affecting agriculture nationwide. For crops such as tobacco, sweet potatoes, and soybeans, which are predominant in North Carolina, the precise and consistent weeding offered by robots can both improve yields and significantly reduce crop damage compared to traditional weeding methods.

Integrating data analytics with robotic weeding technologies can offer farmers real-time insights into field conditions, enabling more accurate interventions. This can be particularly advantageous for managing invasive species or weeds that are resistant to herbicides, a growing concern in our state. By promoting pilot programs and offering subsidies for early adopters, North Carolina can lead the way in sustainable farming innovations, reducing environmental impact while boosting productivity and profitability across its agricultural landscapes.

Conclusion

Robotic weeders are poised to play a pivotal role in the future of agriculture. Their applications range from weed detection and removal to autonomous navigation and mapping in complex agricultural environments. Selective weeding technologies, powered by computer vision and machine learning, enable targeted control, reducing herbicide use by up to 95% for eco-friendly solutions. In the next decade, robotic weeders are expected to become more sophisticated when they can be equipped with even more advanced sensing technologies and AI systems. These enhancements will further improve their accuracy, efficiency, and adaptability. By effectively addressing the challenges of weed control, robotic weeders offer a sustainable and eco-friendly alternative to traditional farming practices, promising a brighter and greener future for agriculture.

References

Edan, Y., G. Adamides, and R. Oberti. 2023. “Agriculture Automation.” In Springer Handbook of Automation, edited by S. Y. Nof. Springer Handbooks, pp. 1055–1078. ↲

Lowenberg-DeBoer, J., I. Y. Huang, V. Grigoriadis, and S. Blackmore. 2020. “Economics of Robots and Automation in Field Crop Production.” Precision Agriculture 21:278–299. ↲

Sapkota, B. B., S. Popescu, N. Rajan, R. G. Leon, C. Reberg-Horton, S. Mirsky, and M. V. Bagavathiannan. 2022. “Use of Synthetic Images for Training a Deep Learning Model for Weed Detection and Biomass Estimation in Cotton.” Scientific Reports 12(1):19580. ↲

Singh, S. P., S. Rawal, V. K. Dua, S. Roy, M. J. Sadaworthy, and S. K. Chakrabarti. (2018). “Weed Management in Conventional and Organic Potato Production.” International Journal of Chemical Studies 2(6): 24–38. ↲

Smith, R. 2016. 2015 Evaluation of Intelligent Cultivators for Use in Lettuce Production. UC Weed Science. ↲

Steward, B., J. Gai, and L. Tang. 2019. “The Use of Agricultural Robots in Weed Management and Control.” In Robotics and Automation for Improving Agriculture, edited by J. Billingsley. Burleigh Dodds Science Publishing, pp. 161–186. ↲

Walz, E. 2004. Final Results of the Fourth National Organic Farmers' Survey. Organic Farming Research Foundation. ↲

Zhang, W., Z. Miao, N. Li, C. He, and T. Sun. 2022. “Review of Current Robotic Approaches for Precision Weed Management.” Current Robotics Reports 3(3):139–151. ↲

Publication date: Oct. 17, 2024

AG-972

Recommendations for the use of agricultural chemicals are included in this publication as a convenience to the reader. The use of brand names and any mention or listing of commercial products or services in this publication does not imply endorsement by NC State University or N.C. A&T State University nor discrimination against similar products or services not mentioned. Individuals who use agricultural chemicals are responsible for ensuring that the intended use complies with current regulations and conforms to the product label. Be sure to obtain current information about usage regulations and examine a current product label before applying any chemical. For assistance, contact your local N.C. Cooperative Extension county center.

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.