Introduction

Turbidity is a measure of the clarity of water. The greater the amount of suspended solids in the water, the murkier it appears and the higher the measured turbidity. The major source of turbidity from construction- and development-related activities is sediment. Fine sediments (clay and fine silt) are so slow to settle that water containing them will remain turbid for days or weeks even if held in a settling or stilling basin. Turbidity can have a number of undesirable effects on the environment. Heavy suspended sediment loads and turbidity reduce light penetration for aquatic plants, fill lakes and bays, and smother benthic habitats. Fine particulate material also can clog or damage sensitive gill structures, decrease their resistance to disease, prevent proper egg and larval development, and potentially interfere with feeding. Very high levels of turbidity for a short period of time or lower turbidity for longer periods can both have significant impacts on aquatic organisms. Turbid water also tends to absorb sunlight, increasing temperature and decreasing the dissolved oxygen level, and stressing or even killing the organisms in the water.

Stilling Basins

A stilling basin facilitates the settling of suspended sediment and solids in water being pumped from excavated areas of a construction site (Figure 1). The water is temporarily stored to allow the suspended sediment to settle to the bottom of the basin, while the “cleaner” water is slowly released over a period of time. A pump hose can be inserted into a corrugated pipe where solid blocks of flocculant are placed. The water is dosed with the flocculant as it passes over the blocks and the resulting flocculated sediment settles in the basin. This works reasonably well for sand- and coarse silt sized particles, but finer particles do not settle in the retention times typical of stilling basins (24 to 48 hours). Hence, highly turbid water is often released from the basins.

Sediment Bags

When space is not available or pumping will be limited, a geotextile bag is often used to retain sediment in water being pumped from a construction site (Figure 2). There are many different sediment bags on the market, varying in size and material depending on the pumping rate, sediment content, and particle-size retention need. To function well, they should be placed on a bed of washed stone so that all sides of the bag can release water. The bags are typically buried on site after they are full of sediment.

Reducing Turbidity

Generally, neither the stilling basin nor the sediment bag retains enough clay and fine silt-sized materials (<0.02 mm) to reduce turbidity to desired levels when these materials are in the pumped water. One solution to this problem is to add a chemical that causes the suspended particles to stick to each other, a process called flocculation. This practice is common in water and wastewater treatment and in numerous industrial processes. There are many chemicals such as gypsum, alum, polyaluminum sulfate, polyacrylamide (PAM), and others, which are used to enhance settling of fine particles. This fact sheet focuses only on PAM because of its advantages of working well in a variety of situations, low cost due to low doses needed, and availability to the construction industry. Polyacrylamide is available in anionic, non-ionic, and cationic forms, but only anionic PAM is referred to here. Anionic PAM is considered relatively non-toxic and safe for aquatic organisms.

PAM’s effect on the smaller suspended sediment particles is to bind many small particles together into what are called flocs. The PAM molecules are very long, allowing them to pull many particles into each floc, which then settles out of the water column. To ensure maximum contact between the PAM molecules and sediment particles, turbulence is needed after the point of dosing. You can read more about PAM in the referenced factsheet on treating turbidity on construction sites.

Using PAM for turbidity control requires that the pumped water be treated or dosed with PAM prior to entering the basin or bag. The two main approaches to achieving this are to inject a solution of PAM into the pumped water, or to use the pumped water to dissolve solid PAM as the water flows into the basin or bag. It is important to select the correct PAM for the sediment on your site. This can be done with a simple jar test, a service often offered by PAM suppliers. A jar test consists of adding a small amount of PAM to a container containing sediment or muddy water to see if it flocculates. Usually several PAMs are tested in separate jars, and the one which forms the flocs fastest is selected.

Pumped Injection

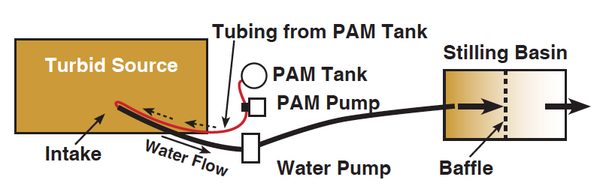

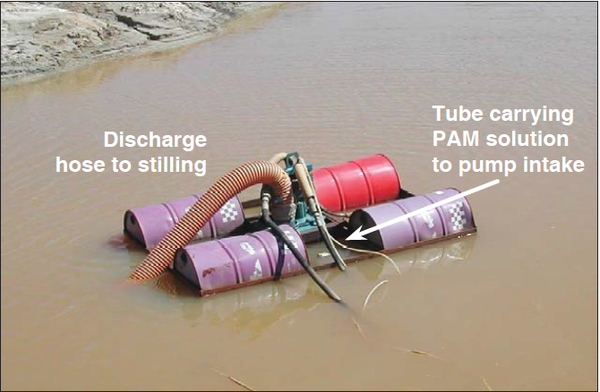

The components of a pumped injection system are a PAM solution pump and a PAM reservoir. The solution is usually injected using a small electric pump, preferably with multiple or variable speeds. Because the concentrated PAM solution is typically quite viscous, peristaltic (rollers on tubing) pumps are preferred as they are less sensitive to the thickness of these solutions. Typically they can pump up to 30 gallons per hour, but the PAM pumping rate is dictated by the expected water pumping rate. The simplest dosing location is in the intake hose to the water pump—simply running the PAM pump hose up into the intake hose will ensure good dosing and provide more mixing and contact time as the water runs through the pump and hoses. A sample layout is shown in Figure 3. A porous baffle of coir netting is recommended to capture any floating flocs (see referenced fact sheet on baffles). Coir, or coconut, netting is available at most erosion-control supply dealers and is available in a variety of weights, but the preferred weight for stilling basins is 900 grams per m2. An actual pump intake for a borrow pit dewatering operation is shown in Figure 4, and the tubing from the PAM pump to the intake is evident in the picture. Mixing and contact time can be improved by releasing the water into a corrugated pipe placed between the pump outlet hose and the stilling basin.

The recommended dosing rate is 1 to 5 milligrams per liter or parts per million (ppm). Higher dosing rates are not recommended because turbidity usually will not be reduced above these levels. The rate can be determined from a jar test or by adjusting the PAM pump during system operation. A jar test involves first dosing the turbid water with different PAMs to find the best one (clears water fastest), then adjusting the dose to find the best rate (least amount of PAM while achieving the turbidity goal). The PAM will need to be dissolved first so the resulting solution, with a known concentration of PAM, can be added to a known volume of turbid water. The following table provides some examples of water and PAM pump rates.

| PAM Solution Concentration | Turbid Water Pump Rate | PAM Pump Rate | |

|---|---|---|---|

| (lb/100 gal) | (gal/min) | oz/min | gal/hr |

| 0.5 | 100 | 21 | 10 |

| 0.5 | 2,000 | 430 | 200 |

| 1 | 100 | 10 | 5 |

| 1 | 2,000 | 215 | 100 |

The advantages of injecting a solution of PAM into the pumped water are that the concentration in the resulting discharge is known and the reaction between PAM and the particles is relatively fast. Because dissolved PAM molecules are fully extended (they are very long molecules), they are ready to bind to suspended sediment as soon as they are injected into the turbid water. The disadvantages of liquid injection are that it requires that a reservoir of PAM solution be available whenever the pump is being operated and a pump and power source must be available to do the injection. Adding PAM to turbid water being pumped into a bag will tend to clog or “blind” the pores and may require replacing the bags more frequently than if no PAM was used. This should be factored into cost estimates if PAM will be used in conjunction with sediment bags. How often they will need to be changed depends on pumping rate and frequency, sediment loading, bag size, and other factors unique to each setting.

Solid PAM Dosing

There are a number of options for flocculating pumped, turbid water with PAM. One is to pump the water over a block of solid PAM, which dissolves as the water flows over it. These blocks are commercially available through erosion- and sediment-control supply companies. The right formulation of PAM in the block should be determined for the sediment in your water using the same jar test mentioned above. One or more of the blocks should be placed so that the pumped water flows over them but its force does not tear off pieces. This can be achieved by pumping into a corrugated pipe (12 inches or larger) or a lined ditch that slopes into the stilling basin. Encasing the PAM block in hardware cloth or similar materials may provide some insurance that the block does not break apart during pumping (Figure 5). The longer the distance from the basin the better, because this allows the PAM molecules to dissolve, unfold, and bind to the suspended particles. Another option to enhance treatment is to place the blocks in corrugated pipes and channel the flow through those to maximize contact and mixing (Figure 6).

This system requires considerable tinkering to achieve the optimal result. Changing the number of blocks, their position relative to the hose outlet, the distance from the stilling basin, and other factors will affect system performance. There are other potential ways to dose with logs, such as creating a flume with baffles and PAM blocks or a circulation tank with blocks suspended in it. The system devised needs only to ensure that flowing, turbid water passes over the blocks, the blocks are not allowed to dry out, and there is some turbulence and mixing prior to discharge into the basin.

Another approach to PAM dosing is to line a channel or ditch with jute or coir erosion control fabric and apply PAM powder to the fabric. The turbid water can be pumped into the ditch, which should discharge into a stilling or sediment basin. The powder will dissolve much faster than the blocks because it is spread thinly over a larger area, so this system needs to be recharged with powder when the operator determines it is no longer evident on the fabric. A similar technique of applying PAM powder to fiber check dams (wattles) has been used successfully in treating sediment in stormwater (Figure 7). The PAM powder should not be applied to flowing or standing water, as it will not dissolve or reduce turbidity but will simply fall to the bottom. It should be applied to the fabric when no water is in the ditch. Wet fabric will hold the PAM powder much better than dry fabric. Only a thin coating is required—a thick coat will form a gel that can easily break off during pumping, ending up at the bottom of the basin and not helping with turbidity at all.

Although solid dosing is much simpler and less expensive than the PAM pumping system, it is more difficult to optimize the flocculation reaction. Problems occur, such as sediment coating the block or powder and reducing PAM release, inadequate numbers of blocks for the flows, or variable water pumping rates that either do not release sufficient PAM, damage the blocks, or erode the powder. In addition, the concentration of PAM in the treated water is unknown, which may concern regulatory agencies. One manufacturer has estimated that the concentration at optimal flows (60 to 70 gallons per minute per block) will result in a PAM concentration of close to 2 ppm, which is in the optimal range for flocculation and well below aquatic toxicity levels. However, conditions vary, and the concentration will be likely different in every case. Careful attention to setting up a solid PAM treatment system with just enough flow and blocks to reduce turbidity will prevent overdosing. This system also must be used with a stilling basin because sediment bags require a pressurized discharge.

The PAM systems described here have been proven to work under a variety of conditions and are relatively simple and inexpensive to install and use. They can bring turbidity down more than 90 percent, usually below levels cited in water quality guidelines. They typically require only that pump operators make sure that the system is charged with PAM and that the water is being treated whenever the pump is running. Using these systems effectively will help prevent one source of sediment and turbidity from harming our streams, lakes, and estuaries.

References

McLaughlin, R. A. 2015. Using Baffles to Improve Sediment Basins. AG-439-59. Raleigh, NC: NC State Extension.

McLaughlin, R. A. 2015. Chemical Treatment to Control Turbidity on Construction Sites. AG-439-62. Raleigh, NC: NC State Extension.

Publication date: May 6, 2014

Revised: Oct. 24, 2019

AG-439-68

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.