Shank Fumigation: Strengths and Limitations

Shank fumigation is a long-established method for applying soil fumigants in vegetable production systems and has historically served as the standard approach for managing soilborne pathogens, plant-parasitic nematodes, and certain weeds. This method involves injecting fumigants 8 to 12 inches below the soil surface using metal shanks, followed by immediate sealing of the soil with plastic mulch. When properly applied, shank fumigation provides relatively uniform vertical placement of the fumigant within the soil profile and has demonstrated consistent efficacy across a wide range of crops and soil types. Its ability to deliver fumigants deeper into the root zone makes it particularly effective in situations where pest pressure extends below the upper soil layers.

Despite its effectiveness, several limitations have increased interest in alternative application methods. Shank fumigation requires specialized equipment that carries high capital and operating costs, including dedicated fumigation rigs, trained operators, and ongoing maintenance. The physical insertion of shanks into the soil increases soil disturbance, which can disrupt bed architecture, alter soil structure, and reduce bed uniformity, factors that are increasingly important in precision plasticulture systems. Applicator safety is another concern, as shank injection can increase the potential for worker exposure during fumigant delivery, particularly under challenging field conditions. In addition, shank fumigation offers limited operational flexibility, as applications must occur before beds are fully formed and covered, restricting the ability to adjust timing once field preparation is complete. Finally, increasing regulatory requirements, including buffer zones and application restrictions, have further constrained the use of shank fumigation in some production areas. Collectively, these challenges are especially impactful for small to mid-size vegetable operations seeking to reduce labor inputs, mechanization costs, and regulatory complexity while maintaining effective soilborne pest management.

Principles of Drip-Applied Fumigation

Drip-applied fumigation uses irrigation water as the delivery mechanism to transport liquid fumigants through the soil profile, integrating fumigant application directly into existing drip irrigation infrastructure. In this system, fumigants are injected into the drip line and distributed within the soil according to the movement of water rather than by mechanical placement. As a result, the effectiveness of drip-applied fumigation is closely tied to soil hydraulic properties, irrigation system design, and the timing and volume of water applied before, during, and after fumigant injection.

A fundamental principle of drip-applied fumigation is that fumigant movement follows the wetting front created by irrigation, rather than gravity alone. Lateral and vertical distribution are therefore governed by soil texture, structure, compaction, and antecedent moisture conditions. Fine-textured soils generally promote greater lateral movement, while coarse-textured soils tend to favor vertical movement with limited horizontal spread. Soil moisture status at the time of application is especially important, as soils near field capacity allow more uniform fumigant movement, whereas excessively dry or saturated soils can restrict distribution or create uneven treatment zones. The use of plastic mulch, particularly totally impermeable film (TIF), further enhances fumigant retention by limiting atmospheric losses and increasing the effective concentration of fumigant within the bed. Although application depth under drip fumigation is typically shallower than with shank injection, depth and coverage can be adjusted through irrigation volume, injection duration, and post-application water management. When properly designed and managed, drip-applied systems can deliver effective fumigant concentrations to the crop root zone while reducing off-site movement and improving application efficiency.

Advantages of Drip-Applied Fumigation

Drip-applied fumigation provides several important operational and economic advantages, particularly in plasticulture systems where drip irrigation is already part of standard production practices. Because fumigants are delivered through the irrigation system rather than injected mechanically, soil disturbance is minimized, resulting in improved bed uniformity and reduced disruption of soil structure. This is especially beneficial in systems that rely on precise bed dimensions and consistent planting geometry. When drip irrigation infrastructure is already installed, drip-applied fumigation also reduces the need for specialized fumigation equipment, lowering both capital investment and operating costs. Worker safety is enhanced due to the enclosed nature of the delivery system, which reduces direct exposure during application. In addition, drip fumigation offers greater flexibility in application timing, allowing fumigants to be applied after beds are formed and covered with plastic mulch, which can improve scheduling efficiency. The method is also highly compatible with precision irrigation and fertigation systems, making it well suited for modern, sensor-informed production practices.

Despite these advantages, drip-applied fumigation is not universally interchangeable with shank fumigation and requires careful management to be effective. Its success depends heavily on uniform drip irrigation performance, as uneven water distribution can result in untreated zones within the bed. Efficacy may be reduced in dry, coarse-textured, or highly structured soils where lateral water movement is limited, and fumigant distribution remains shallow compared with shank injection. Inadequate drip tape spacing or insufficient flow rates can further increase the risk of incomplete coverage, particularly near bed shoulders or deeper in the profile. Additionally, drip systems are susceptible to emitter clogging if filtration and maintenance are inadequate, which can compromise fumigant delivery. As a result, drip-applied fumigation is more management-intensive and less forgiving of system design flaws than shank application, requiring careful planning, monitoring, and verification to achieve consistent soilborne pest control.

Critical System Design and Management Considerations

For drip-applied fumigation to successfully substitute for shank fumigation, careful attention must be given to system design and management. The drip irrigation system must be properly engineered, using high-quality drip tape with uniform emitter spacing and flow rates to ensure consistent fumigant distribution along the bed. Adequate filtration is essential to prevent emitter clogging, and pressure regulation is required to maintain uniform delivery across the field. Soil moisture conditions at the time of application are equally critical; soils should be near field capacity to allow effective lateral and vertical movement of the fumigant. Excessively dry soils limit fumigant transport, while saturated conditions increase the risk of uneven distribution and reduced efficacy. Application strategy plays a key role, including pre-irrigation to establish a continuous wetting front, fumigant injection durations that are matched to irrigation volume and bed geometry, and post-application irrigation to facilitate distribution without promoting excessive leaching. Finally, monitoring and verification are necessary to reduce application risk, including the use of soil moisture sensors or dye tests to confirm wetting patterns and routine inspection of drip lines prior to fumigant injection to ensure system integrity.

Importance of Bed Architecture in Drip-Applied Fumigation

Bed architecture plays a central role in determining the success of drip-applied fumigation because it directly controls how water, and therefore the fumigant, moves within the soil profile. Unlike shank injection, which places fumigant at a defined depth, drip-applied fumigation relies on the wetting pattern created by the drip tape to distribute the product laterally and vertically within the bed. Bed width, height, and shape influence the size and continuity of the wetted zone and determine whether fumigant concentrations reach the full root zone of the crop.

Raised bed height affects vertical movement and retention of fumigants. Taller beds generally promote greater fumigant confinement under plastic mulch but require sufficient irrigation volume to move the fumigant downward without bypassing the target zone. Shallow beds may limit vertical distribution, increasing the risk of untreated zones below the drip line. Bed width influences lateral movement, particularly in coarse-textured soils where water spreads less horizontally. Wide beds with a single drip line may result in incomplete lateral coverage, reducing fumigant efficacy near bed shoulders and crop rows.

The placement and number of drip tapes within the bed must be matched to bed dimensions and soil texture. Single-line systems may be adequate for narrow beds and fine-textured soils, while wider beds or sandy soils often require dual drip lines to achieve uniform fumigant distribution. Bed compaction and internal soil structure also affect fumigant movement; uneven compaction can create preferential flow paths, leading to localized over- or under-treatment.

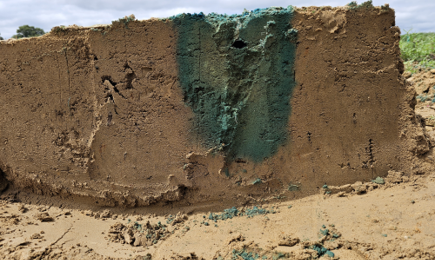

Because fumigant movement is constrained by the wetted volume, bed architecture must be evaluated in advance of application. Dye tests or soil moisture monitoring can be used to confirm that the wetted zone encompasses the intended treatment area (Figure 1). Designing bed architecture with drip fumigation in mind is therefore essential to ensure uniform pest control, reduce the risk of fumigant escape or leaching, and maximize the likelihood that drip-applied fumigation performs comparably to shank application.

When Can Drip Fumigation Substitute for Shank Fumigation?

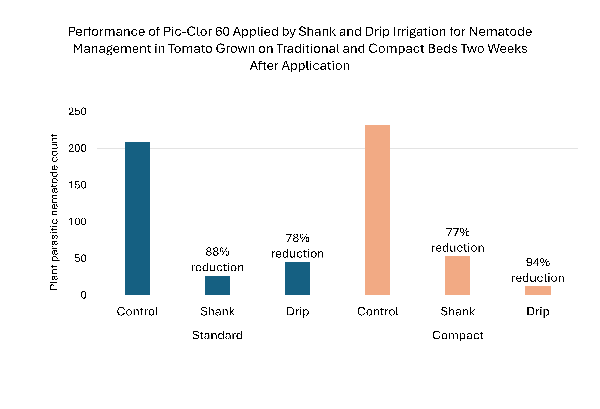

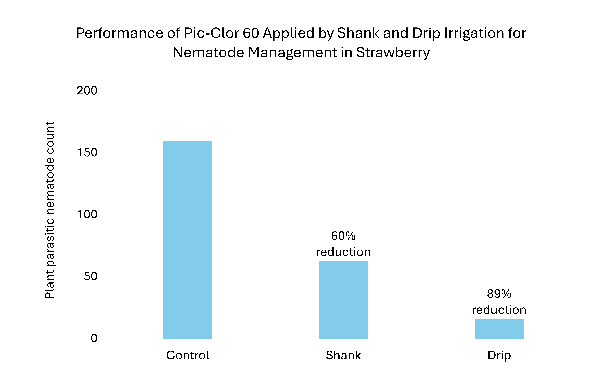

Drip-applied fumigation can effectively substitute shank fumigation in production systems where crops are grown on raised beds covered with plastic mulch and supported by well-designed, properly maintained drip irrigation systems. This approach is most suitable when pest pressure is moderate and largely confined to the upper portion of the root zone, where fumigant distribution through the wetted soil volume can be effectively achieved. Drip fumigation is particularly attractive for growers seeking to reduce labor requirements, minimize soil disturbance, and lower equipment and application costs while maintaining effective soilborne pest management. In contrast, shank fumigation may still be preferred in fields with deep or severe nematode pressure, in very sandy soils where lateral water movement is limited, or in situations that require maximum depth and uniformity of fumigant placement throughout the soil profile. Research conducted by the Torres Lab in 2025 demonstrated that, under North Carolina production conditions, drip-applied fumigation provided nematode and weed control comparable to shank fumigation in both strawberry and tomato production systems when irrigation design and bed architecture were properly managed.

Figure 2. Plant-parasitic nematode populations in strawberry following application of Pic-Clor 60 by shank injection or drip irrigation, compared with a non-fumigated control. Nematode counts represent total plant-parasitic nematodes recovered from soil samples collected from the strawberry root zone at two weeks after fumigation.

Take-Home Message

Drip-applied fumigation can be a practical and effective alternative to shank fumigation for many specialty crop plasticulture systems, but its success depends far more on irrigation design, soil moisture management, and bed architecture than on the fumigant itself. When drip systems are uniform, beds are properly designed, and applications are carefully managed, drip fumigation can provide pest control comparable to shank injection while reducing soil disturbance, equipment costs, and application risks. However, drip fumigation is not a universal replacement; shank fumigation remains advantageous under deep nematode pressure, very sandy soils, or when maximum depth and uniformity of fumigant placement are required. In short, drip fumigation works best as a systems-based decision, not a one-size-fits-all substitution, and should be adopted only when irrigation performance and bed design can reliably support effective fumigant distribution.

Publication date: Dec. 30, 2025

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.