Introduction

Just a decade ago, many public officials and business owners thought of waste materials such as grass clippings, food scraps, and sludge as a problem they had to dispose of. But more and more often, public agencies and entrepreneurs are turning this former problem into a profit with environmental benefits.

Once they’re converted into compost, organic wastes—which are the compostable portions of the solid waste stream—can be used to mulch landscaping, enhance crop growth, enrich topsoil, and provide other benefits.

The change in outlook about municipal organic wastes stems from many factors:

- Municipal officials have realized that composting is an effective strategy for managing waste (up to 70% may be organic)

- Many states have banned certain organic materials such as cardboard and yard waste from landfills

- Backyard composting has been readily accepted

- Composting has been heavily promoted in the agricultural sector

- More markets for compost have opened up

The key to starting a successful composting enterprise is to understand the basics, including how composting works, what types of facilities can handle this process, which raw materials work best, how to manage odor, and how to produce and market high-quality products.

Composting Basics

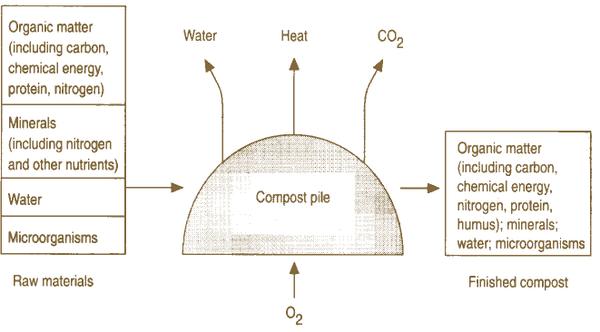

Composting is the aerobic decomposition of organic materials by microorganisms under controlled conditions into a soil-like substance called compost (Figure 1). During composting, microorganisms such as bacteria and fungi break down complex organic compounds into simpler substances and produce carbon dioxide, water, minerals, and stabilized organic matter (compost). The process produces heat, which can destroy pathogens (disease-causing microorganisms) and weed seeds.

Raw materials are composted fastest when conditions that encourage the growth of the microorganisms are established and maintained. The most important conditions include the following:

- Organic materials blended to provide the nutrients that support microbial activity and growth, including a balanced supply of carbon and nitrogen (C:N ratio)

- Sufficient oxygen to support aerobic organisms

- Moisture levels that uphold biological activity without hindering aeration

- Temperatures needed by microorganisms that grow best in a warm environment

As soon as appropriate materials are mixed into a pile, the microorganisms set to work and the composting process begins. During this active stage, oxygen consumption and heat generation are at their highest levels. Then a curing period follows, in which materials compost much more slowly. Decomposition of organic material will continue until all of the nutrients are consumed by microorganisms and most of the carbon is converted to carbon dioxide. Before it reaches this point, however, compost is judged to be finished according to its intended use and factors such as C:N ratio, oxygen demand, temperature, and odor.

Factors affecting the composting process include nutrient ratio, moisture content, oxygen concentration, pH, surface area, temperature, and retention time. Table 1 displays the desirable conditions for the composting process.

| Characteristic | Reasonable range | Preferred range |

|---|---|---|

| Carbon-to-nitrogen (C:N) ratio | 20:1 – 40:1 | 25:1 – 35:1 |

| Moisture content | 40% – 65% | 50% – 60% |

| Oxygen content | > 6% | ~16% – 18.5% |

| pH | 5.5 – 9.0 | 6.5 – 8.0 |

| Bulk density | < 40 lbs per cubic foot | — |

| Temperature | 113°F – 150°F | 130°F – 140°F |

| Particle size | 1/8 in – 2 in diameter | Varies* |

| *Depends on raw materials, pile size, and/or weather conditions. | ||

Nutrients. Carbon (C) and nitrogen (N) are important nutrients needed by microorganisms in the composting process. Carbon supplies energy and growth, and nitrogen is used for protein and reproduction. Since nitrogen is also a major nutrient required for plants, its concentration affects the value of the compost. In general, about 25 times more carbon than nitrogen is needed by biological organisms, so it is important to provide the right ratio. Although good results can be achieved with C:N ratios from 20:1 to 40:1, the ideal ratio is 25:1 to 35:1 for active composting. Table 2 displays the average carbon-to-nitrogen ratios of certain raw materials.

| Material | Ratio |

|---|---|

| High Nitrogen Materials | |

| Alfalfa | 13:1 |

| Blood or bone meal | 3:1 – 4:1 |

| Coffee grounds | 20:1 |

| Cow manure | 20:1 |

| Food scraps | 15:1 – 25:1 |

| Grass clippings | 15:1 – 25:1 |

| Horse manure | 30:1 |

| Llama, donkey, alpaca manure | 15:1 – 25:1 |

| Pig manure | 5:1 – 7:1 |

| Poultry manure | 5:1 – 7:1 |

| High Carbon Materials | |

| Bark | 100:1 – 130:1 |

| Cardboard | 200:1 – 500:1 |

| Leaves | 30:1 – 80:1 |

| Mixed paper | 150:1 – 200:1 |

| Newsprint | 560:1 |

| Wheat straw | 140:1 – 150:1 |

| Wood chips | 200:1 – 700:1 |

Moisture

Microorganisms need water to support their metabolic processes and to help them move about. A moisture content range of 40% to 60% is recommended for most materials. Below 40%, microbial activity slows. It ceases below 15%. When moisture levels exceed 65%, air in the pore spaces of the raw materials is displaced by water, which leads to anaerobic conditions, odors, and slower decomposition.

Oxygen

The composting process consumes large amounts of oxygen. If there is not enough oxygen, the process slows, and odors may result. An oxygen content of 16% to 18.5% is ideal; at 6% or lower, odors are perceptible to even the least sensitive individuals. To increase oxygen for the composting process (aeration), the pile can be turned or aerated with force through blowers. Anaerobic conditions may be minimized by keeping piles at the right height; using a well-mixed, uniform feedstock; avoiding excess moisture; and turning and mixing the pile frequently.

pH

The pH level is an indicator of the acidity or alkalinity of the composting material, measured on a scale from 0 (very acidic) to 14 (very basic), with 7 being neutral. Composting can work effectively between the pH levels of 5.5 to 9; however, the process is most effective between 6.5 to 8.0. A pH level below 6 can slow decomposition, and a level above 8 can cause the release of unpleasant-smelling ammonia. Insufficient oxygen is often the cause of low pH during the active composting stage, so increasing the aeration by turning the pile should raise the pH. It is not advisable to adjust the pH by adding limes and ashes because these materials can increase ammonia losses.

Surface area

Smaller particles of raw materials have more surface area, which makes nutrients and energy more available to microorganisms. However, smaller particles can reduce the air space within the composting mass, so a balance is necessary; particle sizes ranging from 1⁄8 to 2 inches in diameter generally produce good results.

Temperature

Microorganisms release heat while they work, so temperature is a good indicator of the composting process. Temperature increases are noticeable within a few hours of forming a pile or a windrow (long, narrow pile), and they typically increase to 120 to 140°F and remain there for several weeks depending on the size of the system and composition of raw materials. Temperatures within the pile or windrow will gradually drop to 100°F as active composting slows and level out to ambient air temperature.

Retention time

The length of time required to convert raw materials to compost depends on the six factors described above. The shortest composting period results from proper moisture content and C:N ratio, plus frequent aeration. The process will be slowed if there is insufficient moisture, low temperatures, a high C:N ratio, large particles, a high percentage of woody materials that are resistant to decomposition, and inadequate aeration. Active composting takes two weeks to nine months, depending on the method and materials; curing generally requires another one to four months. The intended use of the compost ultimately determines the required composting period.

Types of Facilities

Composting facilities are aerated or unaerated and covered or not covered. Composting methods include passive piles, windrow composting, static piles, and in-vessel composting (in bins, beds, silos, transportable containers, and rotating drums).

Passive piles are created by stacking materials in piles and allowing them to decompose over a long time with little management. This simple, inexpensive method also has some disadvantages: the pile can overheat and spontaneously combust; it can become anaerobic and release odors; it sits there for years, taking up valuable space; and it can look like a dump and attract the dumping of unwanted materials. Passive piles can take a year or more to decompose, depending on the materials in the piles.

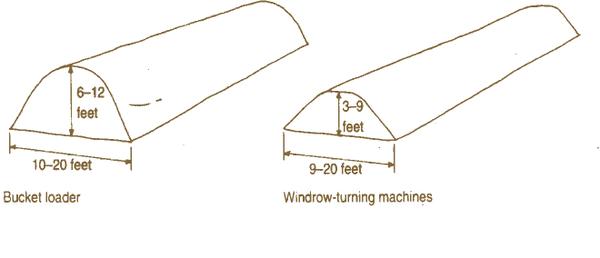

Windrow composting involves placing mixed materials in long, narrow piles and turning or agitating them regularly (Figure 2). This is the most common method used for rapid composting of yard wastes. Windrows are typically 3 to 12 feet high, 10 to 12 feet wide, and hundreds of feet long. Windrows are formed using a front-end loader, and they are turned with this equipment or a specialized turning device. This method is more labor-intensive than aerated piles because some activity is performed on the site almost daily.

Determining how often to turn windrows depends on the rate of decomposition, moisture content and porosity of the materials, and the desired composting time. High-nitrogen or easily degradable materials may require daily turnings at the beginning of the process and weekly turning later. The active composting stage will last three to nine weeks, depending on the type of materials and frequency of turning. To produce compost in three weeks, turn windrows once or twice each day for the first week and every three to five days thereafter.

A static pile is a passively aerated system that has no need for turning because air is supplied through perforated pipes embedded in the piles or windrows. The open ends of the pipes allow air to be drawn in and circulated through the piles or windrows through a chimney effect created by rising hot gases.

A variation on this approach is the aerated static pile system, which uses a blower to supply air to the compost pile. This system allows larger piles, and composts materials in three to five weeks.

In-vessel composting refers to a diverse group of methods that confine the composting process within a container, building, or vessel and uses a combination of forced aeration and mechanical turning to speed up the composting. Compared to windrow and aerated pile methods, these systems require less labor and land area and offer potentially better odor

control, faster composting (in a matter of days as opposed to weeks), and consistently good compost. However, in-vessel systems have high capital, operating, and maintenance costs, ranging from $40 to $150 per wet ton of waste. Because of the high costs, these systems are not usually used to compost yard waste; they are used more often to compost sludge, mixed solid waste, and other hard-to-manage materials.

Equipment requirements depend on the technology used. All that is needed for a static pile is a front-end loader and a screen to sift the compost; an aerated static pile also needs a perforated pipe and a blower. For a windrow operation, equipment might include a front-end loader, chipper, tub grinder, screen (depending on end-use), windrow turner (for large sites), and a dump truck. Equipment needed for in-vessel systems depends on the process. In any operation, having properly sized equipment makes manpower more efficient. It is very important to set a maintenance schedule because equipment maintenance is the key to an operation’s success. Tools needed to maintain equipment may include an air compressor, pressure washer, power and air tools, and a used oil collection and handling system.

In summary, windrow and static pile systems are comparable in cost, labor, management, and speed of process. In-vessel composting is faster, but it has high capital costs with the exception of simple bin methods and some agitated bed systems.

Facility Siting and Development

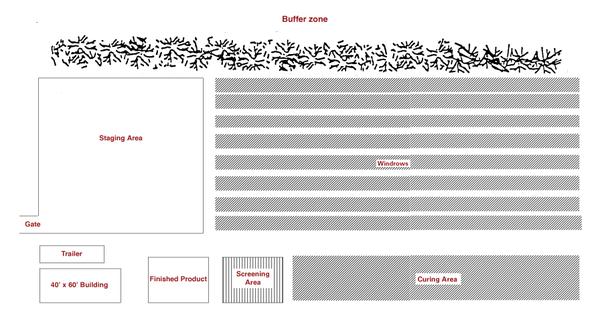

The size of the site required for composting depends on the following factors: the anticipated volume of raw materials, the technology to be used (the higher the level, the less space required), the equipment to be used (which depends on the method and raw materials), and the projections for growth. Some factors that should be considered when choosing a site are: accessibility (roads suitable for traffic and convenient to feedstocks, or raw materials), population density (no houses within half a mile), and type of neighbors (some industries require a clean atmosphere and no flies). Desirable site characteristics include (1) slightly sloped land (for drainage), (2) a firm soil type that packs well, (3) not located in a flood plain, (4) convenient utilities, and (5) a rectangular or square site, which is more efficient than a circular or irregularly shaped site. Figure 3 shows a generic site layout for a composting facility.

The following steps are recommended for site development:

- Grade the site to a 2% to 4% slope

- Slope the site toward a collection pond

- Add minimal paving under the compost (especially for sludge and municipal solid waste)

- Build berms around the perimeter to control run-off and run-on

- Plan areas for raw materials storage, processing, composting, curing, storage, and blending of end product

- Set up equipment in locations convenient to the process

- Construct retainer walls for storage piles

- Develop a screen around the site (fencing/plants/shrubs/trees)

- Build a fence and gate to control access to the site

- Install appropriate utilities depending on the method and process (2-inch minimum water main, storage and tool building, office and lab, maintenance shed)

- Obtain proper permits (this is mandatory)

- local: zoning, building, land use

- state: water discharge, composting, transporting, air, health department

Feedstocks

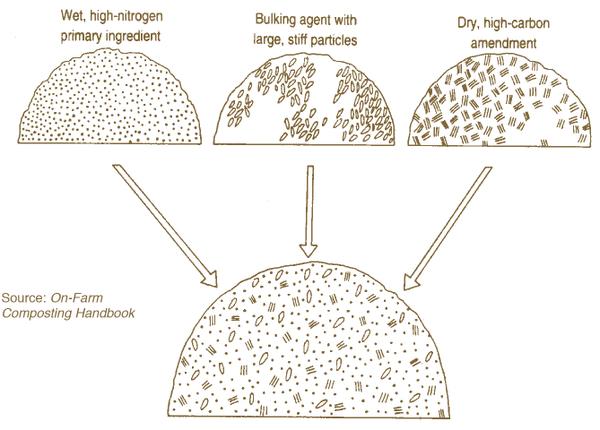

A wide variety of raw materials, or feedstocks, may be used for composting, including yard waste, food scraps, agricultural materials, industrial processing wastes, sludges, and municipal solid waste (Figure 4). Most often there is a primary raw material to be composted and other materials are added. Rarely will an organic material have all of the characteristics needed for efficient composting, so other materials (amendments or bulking agents) must be blended to achieve the desired characteristics. Amendments can be added to adjust moisture content, C:N ratio, or texture. Bulking agents provide structure to hold up materials in a pile and maintain pore spaces for air movement. The desired characteristics of feedstock mixes are summarized in Table 1.

Some of the factors that should be considered when selecting feedstocks include (1) material source and type, (2) collection frequency, (3) condition of materials collected, (4) condition of material as delivered (may differ from when it was picked up), (5) amount of each material type, and (6) daily delivery schedule.

Other feedstock collection criteria include:

- Regulatory constraints

- Content of chemical, organic, and physical contaminants

- Finished product use constraints

- Compatibility with finished product markets

- Compatibility with the composting technology

- Impact on odor generation

- Cost and availability

Raw material recipes are determined primarily by the moisture content and C:N ratio. But degradability, odor potential, and cleanness (degree of contamination from unwanted materials, chemicals, and organisms) also should be considered. Developing a recipe is a balancing act between getting the moisture content and C:N ratio within acceptable ranges. If the moisture content is too high, it can lead to anaerobic conditions, odors, and slow decomposition. If the C:N ratio is below 25:1, odor problems may develop; if the ratio is above 40:1, composting takes a lot longer. Analyzing raw materials for their physical and chemical characteristics helps in developing composting recipes. Important characteristics include moisture content, density, nutrient ratio, and pH.

To establish near-optimum composting conditions, it is important to create composting recipes based on calculations. Using a formula requires a knowledge of the moisture content and the percentage of the dry weight of carbon and nitrogen for each material. There are several compost feedstock mix calculators online.

An Excel spreadsheet that can be used to solve compost mixture calculations for up to four ingredients can be accessed at Cornell’s Compost Mixture Calculation Spreadsheet.

If the goal is simply to compost leaves, then calculations are not necessary. Leaves will compost slowly on their own; however, adding nitrogen (through grass clippings, manure, or nitrogen fertilizer) will accelerate decomposition. A rule of thumb is to add one part grass clippings to three parts leaves, or two pounds of nitrogen fertilizer to a cubic yard of leaves.

Permit Requirements for North Carolina

Anyone desiring to produce compost from solid waste, yard debris, agricultural products, or processing waste should contact the Solid Waste Section, Division of Waste Management, Department of Environmental Quality, to learn if a permit is required. The North Carolina Administrative Code (NCAC) sets forth requirements for siting, design, application, operation, product distribution, testing, and reporting in “Solid Waste Compost Facilities,” 13B, Section .1401. Permits are not required for backyard composting, farming or silvicultural operations in which compost is produced from materials grown and reused on the owner’s land and not offered to the public, people receiving 30 cubic yards of leaves or less annually from an offsite source, and for small Type 1 facilities.

Solid waste compost facilities in North Carolina are classified based on the type and amount of materials to be composted. Type 1 facilities may receive yard and garden waste, silvicultural waste, and untreated and unpainted wood. Type 2 facilities may receive pre-consumer meat-free food-processing waste; vegetative agricultural waste; source-separated paper; other source-separated wastes that are low in pathogens and physical contaminants; and waste accepted for a Type 1 facility. Type 3 facilities may receive manures; other agricultural wastes; meat; post-consumer source-separated food wastes; other source-separated wastes that are relatively low in physical contaminants but may contain high levels of pathogens; and waste acceptable for Type 1 and 2 facilities. Type 4 facilities may receive mixed municipal solid waste, post-collection separated or processed waste, industrial solid waste, nonsolid waste sludges, and waste acceptable for Type 1, 2, or 3 facilities. Hazardous waste, asbestos, and household hazardous waste cannot be accepted at a facility or processed into compost.

Facilities must meet siting requirements under 15A NCAC 13B.1404 for flood plain, buffers, surface water, and groundwater standards. The design requirements must address public access, the state’s Sedimentation Pollution Control Law, Air Pollution Control, and odor minimization.

For more information about composting regulations in North Carolina, visit the NC Department of Environmental Quality’s Composting web page.

Testing

Testing involves collecting and analyzing representative samples of compost for meeting process optimization, safety, compliance, and market standards. Three types of tests may be conducted: field tests, on-site laboratory tests, and off-site lab tests. Common field tests measure temperature, oxygen concentration, odor, color, and noise. On-site lab tests may examine pH, moisture content, bulk density, soluble salts (conductivity), respiration, particle size, seed germination, and man-made inerts. Equipment needed for an on-site testing lab may include a refrigerator, drying oven (a microwave oven is suitable), balance, pH meter, oxygen- measuring device, temperature-measuring device, nest of sieves, and record-keeping material. Off-site lab tests may measure metals content, organic content, pathogens, particle size, respiration, man-made inerts, pH, and odor.

How often compost is tested depends on the amount of information needed, the extent of information already available about feedstocks, and the composting process. More frequent testing is necessary during start-up operations and when new feedstocks are used.

An accurate representation of the area/volume being sampled can be obtained if multiple samples (usually at three places in a pile or windrow) are mixed together. It’s best to take samples after the pile or windrow has been turned. Dig about a quarter of the distance into the windrow or pile at a downward angle and collect about a quart of half-inch sized particles in the compost; collect more if compost mainly consists of larger-sized materials. Label each sample clearly. Assign an ID number, and write down the date, source, name of the sampler, and the method of preservation. Keep a sample log book that includes ID numbers, analyses, and shipment records. Try to collect samples at the beginning of the week so they may be shipped directly to the laboratory and analyzed without waiting over the weekend. If samples must be stored for more than two days, keep them refrigerated.

In North Carolina, samples may be sent to the Waste/Compost Analysis Section of the NC Department of Agriculture and Consumer Services’ Agronomic Division. The staff will analyze samples, interpret analytical results, and offer management recommendations. The Division’s website provides detailed information about their services, how to prepare waste or compost samples, and includes a form to send with your samples.

For further information about testing compost, contact The U.S. Composting Council for its publication Recommended Test Methods for the Examination of Compost and Composting.

Odor Management

Some odor will occur with any composting operation, so odor-control procedures should be included in the planning, design, and operation of compost facilities. The odors originate from three main sources: odorous raw materials, ammonia released from high-nitrogen materials, and anaerobic conditions within windrows and piles. But strong-smelling raw materials cause most of the odors. Sewage sludge, liquid manure, and fish wastes typically present odor problems; leaves, sawdust, crop residues, and fresh-bedded manure do not. The odors can be minimized by starting the materials composting as soon as possible and by keeping them aerobic.

The following recommendations will help minimize odors:

- Develop a good feedstock recipe and keep the feedstock well mixed

- Store raw materials for the least amount of time possible

- Keep pile height at about 4-½ feet

- Maintain pile moisture around 55%

- Turn pile twice a week

- Prevent puddles and standing water (pools of anaerobic activity)

- Minimize dust (it carries odors)

- Keep storage piles contained and dry

- Keep facility tidy (bits of compost lying around can become anaerobic)

Compost Quality and End-Use

The following parameters are conventionally used for indicating compost quality:

- pH (5.5 – 7.5)

- soluble salts (<5 mmhos/cm)

- nutrient content

- water-holding capacity

- stability

- organic matter content

- moisture content (35% – 55%)

- particle size (3/8 inch – 1 inch)

- bulk density (<1,000 lbs/cu yd)

The compost quality guidelines for each of these parameters vary according to end-user specifications. For example, compost to be used as a top dressing for plants is recommended to be less than 1/4 inch in diameter; whereas compost that is less than 1/2 inch in diameter is acceptable for other uses, such as a soil amendment or potting media.

Aesthetic parameters, such as color and texture, are also important because people choose compost products primarily by appearance. For example, a dark compost is assumed to be better than a lighter-colored one.

Compost may be used as a soil incorporant, mulch, turf or other plant top dressing, an amendment to growing mixes, and a blend with topsoil. Currently, the number one use of compost is in planting beds. It is predicted that compost will be used widely for field nursery production.

Some of the benefits of mature compost to soil and plants include its ability to:

- Improve soil structure

- Reduce fertilizer requirements

- Improve water infiltration and drought tolerance

- Reduce soil compaction and crusting

- Improve root growth and yields

- Increase microbial and earthworm populations in soil

- Protect plants from disease

- Slowly release nutrients to plants

- Improve nutrient-holding capacity

- Increase ease of cultivation

Compost has also proven to be useful in pollution prevention and remediation. It is being used to prevent erosion of hillsides, embankments, and roadsides. Compost can also bind heavy metals in contaminated soils, degrade many pesticides, and absorb odors and degrade volatile organic compounds. In addition, compost is being used in wetland damage mitigation, storm water filtration, and biofilters.

Marketing

A key to the success of a composting operation is a marketing or distribution program for compost products. To develop long-term markets, the products must be of consistently high quality. Other essential marketing factors include planning, knowledge about end-users, following basic marketing principles, and overcoming possible regulatory barriers and product stigma.

Compost characteristics desired by end-users vary with intended uses, but most compost users look for the following elements (in order of importance):

- Quality (moisture; odor; feel; particle size; stability; nutrient concentration; product consistency; and a lack of weed seeds, phytotoxic compounds, and other contaminants)

- Price (should be competitive with other composts, although high quality and performance can justify a higher price)

- Appearance (uniform texture, relatively dry, earthy color)

- Information (product’s benefits, nutrient and pH analysis, and application rates and procedures)

- Reliable supply

How compost is sold depends on the amount, quality, appearance, and seasonal availability. Most compost is used in spring and early summer. Consider whether to sell compost in bulk, in bags, or both. Bagging expands the potential market because bags can be sold at retail outlets. Bagged compost may be sold at a higher price, which justifies higher transportation costs, and thus, can support a larger market area. The bulk market usually stays at the local level due to high transportation costs. The best markets for bulk sales are local nurseries, landscapers, and home gardeners.

The following are potential end-users for compost:

- Growers (greenhouse, container, sod, field, agriculture, silviculture)

- Landscapers/turf managers (commercial properties, sports turf, residential lawns, cemeteries)

- Government agencies (parks, schools/universities, roadsides/highways, sports turf)

- Companies conducting land reclamation (landfills, sand/gravel pits, strip mines)

- Blenders/resellers (topsoil dealers/brokers, garden centers)

- Companies or agencies involved in environmental projects (wetlands, biofilters, erosion control, soil remediation, water filters)

- Farmers (fruit, vegetable, field crops, organic)

- Owners of golf courses and cemeteries

- Homebuilders and buyers (new home builders, renovators, organic gardeners, homeowners)

Rapidly expanding markets include homeowner use, custom topsoil blending, environmental applications, and agricultural uses.

There are a number of ways to improve the marketing of your compost product. Hire staff who can talk about your products and their uses. Try selling to high-profile markets to get others interested in your products. Plant flower and vegetable gardens at your facility to show compost in action. Exhibit at industry trade shows and get involved with local trade associations. Promote a positive public reaction by conducting tours of your facility and offering hands-on activities for school children, such as planting things using compost. Lastly, contact local radio and television gardening shows about the possibility of interviews.

Figures 1, 2, and 4 are reproduced with permission from On-Farm Composting Handbook, NRAES-54, published by NRAES, Cooperative Extension, 152 Riley-Robb Hall, Ithaca, New York 148553-5701.

Publication date: Jan. 16, 2020

AG-593

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.