Abstract

This factsheet summarizes key technologies used to produce pellets from animal manures and the impact of process variables (temperature, pressure, moisture content) on the final product. The factsheet reviews key quality indices used to evaluate manure pellet quality. It also presents an overview of how scale, cost and environmental benefits, and trade-offs impact technology adoption.

A pdf version of this publication is available from The Learning Store, Division of Extension, University of Wisconsin-Madison.

Manure Processing Series Partners

- University of Wisconsin Platteville, School of Agriculture

- NC State University, College of Agriculture and Life Sciences

- Texas A&M, Agrilife Extension

- University of Idaho, Department of Soil and Water Systems

Introduction

Pelleting is a mechanical process that aggregates solid material to form uniform-sized particles referred to as pellets or granules. The binding action is achieved using any of the following methods: chemical bonding, compression, extrusion, and tumbling. Pellets are favorable to loose solid materials because they are easier to handle, store, and transport. This process allows for creating consistent mixtures of multiple ingredients by avoiding separation by particle sizes or specific gravity. Pelleting is widely used in industrial applications including pharmaceutical drug manufacturing, food processing, and production of fertilizers and animal feed. In addition, wastewater treatment solids (biosolids) are increasingly being pelleted to create commercial fertilizer products. A well-known example is Milorganite, a brand name for granulated biosolids produced by the Milwaukee Metropolitan Sewerage District since 1926 (Kadish 1928). Similar to biosolids, animal manure and composted manure can be pelleted to produce uniform-sized products that are rich in organic matter and nutrients. In addition to use as a fertilizer, pelleted manures can be used as a fuel for heat and power generation (Wzorek et al. 2021, Nagy et al. 2018). Depending on the final use of manure pellets, the pelleting process can be customized by adjusting the particle size (Figure 1) and adding co-ingredients to optimize the pellet nutrient content or energy content. In order to be effectively pelleted, manure needs to have low moisture content. Depending on the manure type, pretreatment steps such as solid-liquid separation, drying, and milling might be necessary before pelleting. It is important to ensure manure storage and processing areas are well-ventilated and monitored to avoid harmful gas emissions, self-heating fires, as well as dust generated during milling and processing.

Technology Basics

Pelleting technologies can be classified based according to how solids are aggregated into: (1) compaction, and (2) balling. The characteristics of the material and intended use of product determine which pelleting technology is preferred. The following sections briefly summarize each pelleting mode and its compatibility with manures:

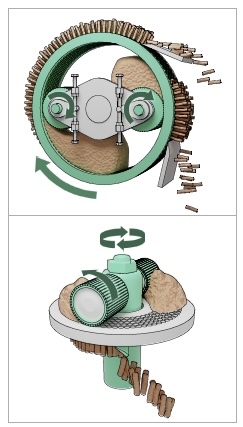

- Compaction (Extrusion): this mode uses compression or extrusion to pressurize solids and form pellets by using equipment such as extruders (Figure 2). Extruders have been used to pellet organic residue such as poultry litter (McMullen et al. 2005), dairy manure (Alcaraz et al. 2018), compost, and crop residues. Extruded pellets are cylindrical with a length, typically ranging from 0.4 to over 2 inches, which could be controlled by an adjustable cutting knife. During extrusion, friction within solid particles and between particles and extruder walls releases heat that can cook the material in the dies causing a blockage. Manure with low fiber content, such as dried swine manure, is not recommended for this technology because of the increased risk of overheating or “cooking” the fine powder onto the extruder surfaces. The product, cylindrical pellets, is not compatible with fertilizer spreaders and requires a crumbling step to achieve ball-like shape. Pellets are more suited for energy production through combustion with other solid fuels (coal, wood chips, etc.).

-

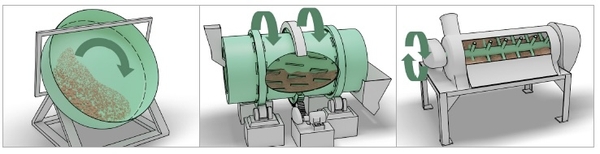

Balling (Granulation): this process is also known as granulation. It relies on tumbling the material ingredients while adding a binder that acts like a glue to encourage the formation of ball-like aggregates (snow balling effect). Pan and drum granulators and pin mixers are popular examples of this technology (Figure 3). These systems are more suited to fine, powder-like feedstocks such as ground swine manure, fiber-free dairy manure, and biochar. The binders used in this process include molasses, starches, alginates, and lignosulfonates (Nikiema et al. 2014). Oil extraction residue (meal), like canola meal, can function as a binding agent and a source of nutrients for manure pellets (Alege et al. 2020). The process is controlled to produce granule size that is compatible with existing fertilizer spreaders, such as rotary or drop spreaders.

Performance

Moisture content, and particle size and shape of feed-stock being pelleted (e.g. raw material, processed manure or compost), strongly affect the quality of the generated pellets. High moisture content in raw material, ≥ 50% moisture content, reduces the pellet durability and increases its bulk density (Pampuro et al. 2017). On the other hand, raw material that is too dry, ≤ 10% moisture content, requires dust collectors to improve working air quality. Drying the produced pellets or granules can increase internal stresses leading to low-durability pellets. The properties of the finished pellets are indicators of the performance of the pelleting process. The following section briefly summarize key pellet properties.

Particle Size Uniformity

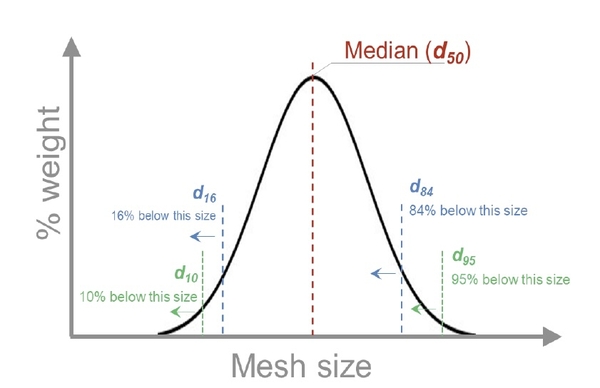

Uniformity of particle sizes for granulated manure is important to ensure it is evenly distributed during land application. In addition, uniform particles are easier to match with standard fertilizer sizes and ensure a uniform spread pattern. Similarly, uniformity of manure pellets used to produce electricity reduces feeding complications or blockages. Particle size distribution is determined using a sieve analysis test (ASABE Standard S319.4, 2007) by weighing the pellets or granules retained on each sieve after a shaking test. The median particle size (d₅₀) is a common indicator used to describe the middle value of the size distribution. The size number guide (SGN), on the other hand, refers to the average particle size, in millimeters (mm), multiplied by 100. The range of sizes in the produced granules is described by the granulometric spread index (GSI) and the uniformity index (UI).

\(\mathrm{GSI}=100\times\frac{\left(d_{84}-d_{16}\right)}{\left(2\times d_{50}\right)}\)

\(\mathrm{UI}=100=\times\ \frac{d_{95}}{d_{10}}\)

Where dN refers to the mesh size (d) in mm that N % of granules mass pass through it (Figure 4). For example, if 95% of a granulated product passes through a US sieve #8, then the d(95) for this product is 2.36 mm or 0.0937 inches. A low GSI value (10 to 20) is preferred as it indicates a uniform product where size segregation is unlikely to occur (Miserque and Pirard 2004). Preferred UI values are greater than or equal to 40 for fertilizer applications.

Bulk Density

The bulk density increases significantly after compaction (extrusion), while granulation only slightly increases the bulk density. McMullen (2005) reported 390% increase in the bulk density of poultry manure pellets due to compaction (from 200 to 780 kg/m³) and Pampuro (2017) reported 280% increase in composted swine manure bulk density after compaction into pellets (from 240 to 680 kg/m³). This increase in bulk density is inversely related to the particle size. By contrast, the higher moisture content of the pellet, the higher its bulk density (Zafari 2012).

Durability

Pellet durability indicates how resistant pellets are to breaking under mechanical stresses. The durability of pelleted manure depends on dimensions, pressure used during production (in case of extrusion), and moisture content. Increasing pellet length or moisture content beyond critical points reduces its durability. Pellet durability is measured according to ASABE S269.4 standard (ASABE S269.4, 2007) by placing a pellets sample (around 500g) in a rotating chamber (tumbling box) for 10 minutes at a speed of 50 rpm. The pellet durability index (PDI) is calculated as follows:

\(\mathrm{PDI}=100\times\frac{m_A}{m_E}\)

Where mA and mE are the mass of intact pellets (retained on sieve for pellet size) after and before test, respectively.

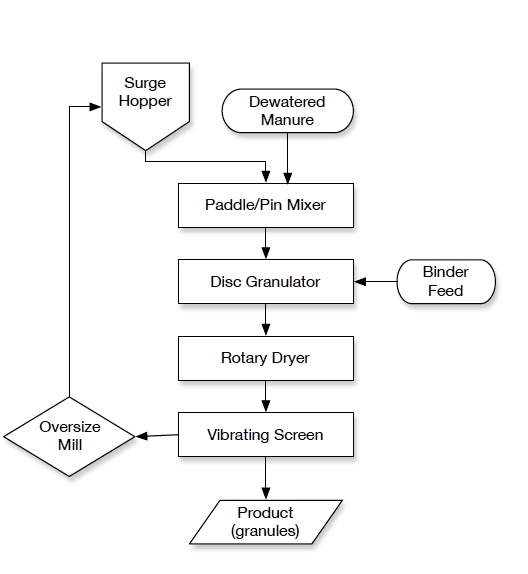

Cost

The pelleting process cost varies widely with the type of equipment and binder used. In addition, manure pellet-ing involves both pretreatment and post-treatment steps. Pretreatment processes includes solid-liquid separation and drying, for liquid and slurry manures such as dairy and swine manures. Post-treatment, on the other hand, can include screening and milling. The capital cost for such system is in the millions of dollars, which makes it only feasible for very large farms (around 15,000 dairy cows) or a cooperative of several farms (WaterWorld 2001). Figure 5 shows a flow chart of a facility that pelletizes dairy manure solids. In a study evaluating the cost of this system to granulate manure from several farms in two counties (total cow populations were 28,854 and 36,402 cows), the cost was between $330 and $343 per ton of granulated product (Sharara et al. 2018). When the cost to acquire the manure was eliminated, the granulation cost dropped to $300 to $313 per ton of product. A comparison between the operating cost for dairy manure granulation and extrusion showed granulation to be at least 3.5 times greater than pelletizing due to the cost of binder and energy required for granulation (Runge et al. 2018).

Environmental Benefits and Trade-Offs

Through pelleting, nutrient-rich manure solids become less expensive to transport and can be fortified with nutrients to achieve desired ratios and bagged for wider distribution. This is particularly useful in areas of dense animal production where available fields for manure land application are limited. Adopting this technology for manure nutrient export can reduce surplus nutrients, particularly phosphorus, which can reduce chronic eutrophication (Sampat et al. 2019). Other benefits of pelleting include reducing odor, vectors, and flies. In addition, the uniform land application of manure pellets expands the potential for precision application of manure-based nutrients It also makes manure nutrients accessible to non-agricultural applications, such as lawns, gardening, and golf courses, which expands the market opportunities for manure. Because of its capital and labor-intensive nature, pelleting is not recommended for small or medium farms unless a niche market exists to support these costs. More commonly, this technology is implemented on mega-farms or at a centralized site that operates as a cooperative serving several operations.

Another consideration with pelleting is the high-energy demand, particularly when relying on natural gas for manure drying. This can increase the carbon footprint of animal production. Relying on low-carbon drying systems, such as ambient or greenhouse drying can significantly lower the greenhouse gas (GHG) emissions associated with this technology.

References

Alcaraz, J., E. Baticados, S. Capareda, A. Maglinao Jr., and H. Nam. 2018. “Drying and pellet characterization of sand separated dairy manure from Stephenville Texas, USA.” Applied Ecology and Environmental Research 16(1):29-38. ↲

Alege, Femi Peter, Gilbert John Miito, Lisa W. DeVetter, Haiying Tao, and Pius M. Ndegwa. 2020. “Effects of Blending Dairy Manure Compost and Canola Meal on Pellets Quality and Nutrients Concentrations.” Transactions of the ASABE 64(2):353-363. ↲

ASABE Standard S269. 4. 1991 (R2007). “Cubes, pellets, and crumbles-definitions and methods for determining density, durability, and moisture content.” St. Joseph, MI: ASABE. ↲

ASABE Standard S319.4. 2008 (R2017). “Method of determining and expressing fineness of feed by sieving.” St. Joseph, MI: ASABE. ↲

Fulton, John, and Kaylee Port. 2016. “Physical properties of granular fertilizers and impact on spreading.” Ohio State University, FABE-550.1. ↲

Kadish, Victor H. 1928. “Milorganite–A New Fertilizer Material.” In-dustrial & Engineering Chemistry 20(1):9-10. ↲

McMullen, J., O. O. Fasina, C. W. Wood, and Y. Feng. 2005. “Storage and handling characteristics of pellets from poultry litter.” Applied Engineering in Agriculture 21(4):645-651. ↲

Miserque, Olivier, and Eric Pirard. 2004. “Segregation of the bulk blend fertilizers.” Chemometrics and Intelligent Laboratory Systems 74(1):215-224. ↲

Nagy, D., P. Balogh, Z. Gabnai, J. Popp, J. Oláh, and A. Bai. 2018. “Economic analysis of pellet production in co-digestion bio-gas plants.” Energies 11(5):1135. ↲

Nikiema, Josiane, Olufunke Cofie, Barbara Asante-Bekoe, Miriam Otoo, and Noah Adamtey. 2014. “Potential of locally available products for use as binders in producing fecal compost pellets in Ghana.” Environmental Progress & Sustainable Energy 33(2):504-511. ↲

Pampuro, Niccolò, Giorgia Bagagiolo, Paolo C. Priarone, and Eugenio Cavallo. 2017. “Effects of pelletizing pressure and the addition of woody bulking agents on the physical and mechanical properties of pellets made from composted pig solid fraction.” Powder Technology 311:112-119. ↲

Runge, Troy M., Mahmoud A. Sharara, and John G. Primm. 2018. “Comparison of dairy manure pelletization to granulation for facilitating farm nutrient export.” In 2018 ASABE Annual International Meeting, American Society of Agricultural and Biological Engineers. ↲

Sampat, Apoorva M., Yicheng Hu, Mahmoud Sharara, Horacio A. Aguirre-Villegas, Gerardo Ruiz-Mercado, Rebecca A. Larson, and Victor M. Zavala. 2019. “Coordinated management of organic waste and derived products.” Computers & Chemical Engineering 128:352-363. ↲

Sharara, Mahmoud A., Troy Runge, Rebecca Larson, and John G. Primm. 2018. “Technoeconomic optimization of community-based manure processing.” Agricultural Systems 161:117-123. ↲

WaterWorld. 2001. “Perdue AgriRecycle opens first pellet fertilizer plant.” July 10, 2001. ↲

Wzorek, M., R. Junga, E. Yilmaz, and P. Niemiec. 2021. “Combustion behavior and mechanical properties of pellets derived from blends of animal manure and lignocellulosic biomass.” Journal of Environmental Management, 290:112487. ↲

Zafari, Abedin, and Mohammad Hosein Kianmehr. 2012. “Effect of temperature, pressure and moisture content on durability of cattle manure pellet in open-end die method.” Journal of Agricultural Science 4(5):203-208. ↲

© 2021 by the Board of Regents of the University of Wisconsin System doing business as the University of Wisconsin–Madison Division of Extension. All rights reserved.

Division of Extension publications are subject to peer review.

Reviewers: Troy Runge is a Professor for the Biological Systems Engineering Department at the University of Wisconsin–Madison; Sanjay Shah is a Professor and Extension Specialist, and John Classen is an Associate Professor. Both are with the Department of Biological and Agricultural Engineering at North Carolina State University.

University of Wisconsin–Madison Division of Extension, in cooperation with the U.S. Department of Agriculture and Wisconsin counties, publishes this information to further the purpose of the May 8 and June 30, 1914, Acts of Congress. An EEO/AA employer, University of Wisconsin–Madison Division of Extension provides equal opportunities in employment and programming, including Title VI, Title IX, the Americans with Disabilities Act (ADA), and Section 504 of the Rehabilitation Act requirements. For communicative accommodations in languages other than English, please contact oaic@extension.wisc.edu. Persons with disabilities who require alternative means for communication of program information (braille, large print, audiotape, etc.) should contact Heather Lipinski Stelljes.

This publication is available from your UW Extension office or from Division of Extension Publishing.

Pelleting Animal Manures (A4192-003/AG-919-03)

1-09-2021

Publication date: Jan. 9, 2021

Reviewed/Revised: Dec. 22, 2025

AG-919-03

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.