Controlled drainage (CD) is a practice that has been applied in North Carolina since the 1980s to reduce nitrogen (N) and phosphorus (P) losses from agricultural land to surface waters and groundwater. Research has shown that proper management of CD systems can also conserve water in the soil profile and alleviate drought stress, which may result in increased crop yields.

Drainage Systems in North Carolina

Agricultural drainage systems are widely used in North Carolina to increase crop yield and improve the year-to-year consistency of production. Drainage systems provide trafficable conditions for timely planting, harvesting, and other field operations, and the systems remove excess water from the root zone to alleviate crop stress that occurs when soils are saturated for extended periods. Drainage improvement can be accomplished through surface drainage (land grading to remove excess surface water following large storm events) and subsurface drainage (ditches or drainpipes that remove excess water from the soil profile).

The most economical way to improve subsurface drainage is to install ditches or subsurface drains as deep and spaced as wide as possible to satisfy production requirements. Typical subsurface drainpipe depths in eastern North Carolina range from 3 to 5 feet, and the pipes are often spaced between 50 to 200 feet apart. Ditches are typically the same depth but are spaced from 150 to 600 feet apart depending on the intensity of surface drainage. These design parameters are typically determined based on outlet conditions, soil types, topography, crop tolerance to wet conditions, and economics. From a farming perspective, the producer's goal is to install a well-designed drainage system that will result in the highest crop yields with the minimum investment possible. However, drainage requirements vary widely for the same farm from year to year and within the same year, depending on weather conditions, cropping system, and farming practices. Therefore, even the best designed systems may overdrain the field (meaning lowering the water table too far below the root zone) during intermittent wet and dry growing periods, causing deficit water stress on crops and increased water and nutrients loss from the farm.

Controlled Drainage

Controlled drainage (CD) is the primary type of drainage water management in North Carolina. It has been applied to reduce nutrient losses from hundreds of thousands of acres in the NC coastal plain since the early 1980s.

A farmer implements CD by installing a water control structure at strategic drainage outlets. The outflow of water from a drainage system is then regulated by controlling the level of water at the drainage outlet. Essentially, CD allows the farmer to adjust the intensity of the drainage system from full, to partial, to no drainage during different times of the year based on the agronomic and farming needs. Thousands of water control structures have been implemented in North Carolina alone, and these structures are a recognized best management practice (BMP) by the U.S. Department of Agriculture's Natural Resource Conservation Service (USDA–NRCS). These systems work well with land slopes less than 0.5 percent, so the practice is most effective in the NC coastal plain.

There are two main types of control structures. The first is an open-ditch flashboard riser structure. Smaller versions can be used directly in field ditches for drainage control of small areas of a field (Figure 1a). Larger structures can be used in outlet canals to control drainage from much larger areas (Figure 1b). The second type of structure is an inline control structure that is attached directly to subsurface drainage pipe (Figure 1c). Like the open-ditch flashboard riser structure, the inline control structure can be placed to control flow from individual subsurface drainage pipes or installed on a subsurface outlet drain that collects flow from multiple subsurface drainage pipes to control the water table on a larger area.

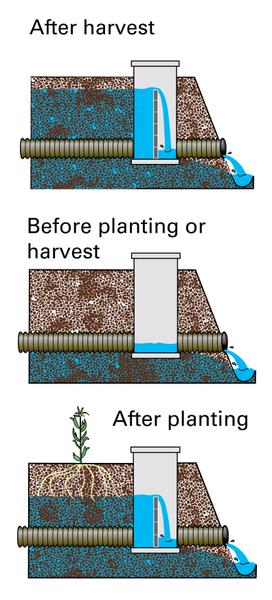

Flashboards, made of treated wood, aluminum, or plastic, are added or removed from the riser to control the water level in the outlet. More boards in the riser structure allow the user to hold water in the outlet at a higher elevation, which decreases drainage rates from the fields. When boards are removed, the drainage rate greatly increases, and the fields can be drained more quickly to allow for tillage, fertilization, or harvest operations. This concept is demonstrated in Figure 2.

Managing the boards allows the operator to control the drainage outflow to help manage the water table level in the fields and soil moisture in the root zone of the growing crop without additional water input. Proper water table management is necessary to achieve maximum crop benefits. Improper management can result in increased crop stress due to excess water in the root zone, which could reduce crop yield.

Structure Locations

When installing a CD system, the user's goal is to strategically place the fewest structures that will achieve adequate control of the water table within the area of interest. When possible, control structures should be placed at the downstream outlet, as this is typically the most efficient and cost-effective location. In some cases, however, this outlet may not be the best location because of other factors—such as legal ownership of the outlet and local topography. If another property owner drains to the same outlet, prior legal arrangements may need to be considered before placing the structure. Because control structures should be placed at locations that will achieve the best and often the most far-reaching control of the water table, final locations should be selected after careful review of topographical data. This data can come from multiple sources: from existing local topographic maps to new data collected using real-time kinematic (RTK) global positioning system (GPS) or light detection and ranging (LIDAR) techniques. LIDAR data for the piedmont and eastern areas of North Carolina can be obtained from NC Flood Plain Mapping Program Spatial Data Download.

Water Quality and Yield Benefits

Controlled drainage has been accepted as a BMP by the NC Agricultural Cost Share Program and the USDA–NRCS Environmental Quality Incentives Program (EQIP) because of its effectiveness in reducing N and P losses to surface waters and groundwaters. Over 4,500 water control structures have been installed in North Carolina under these cost-share programs, providing management to over 400,000 acres (Evans and Skaggs, 2004).

Research has shown that losses of N and P in drainage water can be substantially reduced by controlling drainage outlets during both the growing season and the winter months. Multiyear experiments on a wide range of soils on both farmer-operated systems and on experiment stations in North Carolina showed that CD reduced N losses to surface waters by over 40 percent and P losses by about 25 percent compared to conventional uncontrolled drainage (Gilliam et al., 1979; Skaggs and Gilliam, 1981; Evans et al., 1995; Poole et al., 2018; Liu et al., 2018).

The primary reason for these reductions is that CD limits the volume of drainage water, and thus the delivery of associated N and P, that is discharged from the fields. Holding water tables higher in the field also enhances the potential of N reduction through denitrification—a process where microbes convert nitrate (the primary form of N lost in drainage water) to forms of nitrogen gas.

Controlled drainage has a great potential to conserve water and improve crop yields, especially during dry periods of the growing season. Because CD works by substantially reducing drainage volumes, it increases groundwater recharge, raises the water table, and increases the availability of soil water in the root zone, especially during the hot summer months. These factors can alleviate water deficit conditions and associated stresses on crops. Improved crop yield results in enhanced nutrient uptake and thus better fertilizer use efficiency (Poole, 2018). The result is increased revenue to the producer in addition to enhanced nutrient capture in the crop itself. This capture provides another mechanism that reduces the amount of nutrients that can be lost in the drainage water.

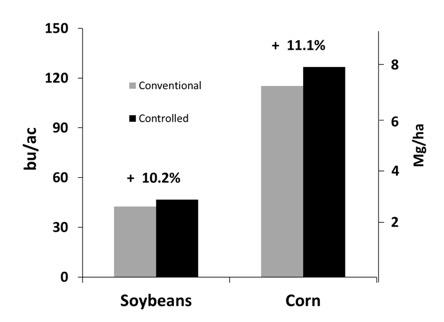

Crop yield benefits with controlled drainage have been documented in North Carolina over the last 20 years. In general, corn and soybean yields can be increased, on average, by 10 percent. In some dry years, yields have been increased as much as 20 percent. Figure 3 shows a comparison of average reported yield data from North Carolina from 1991 through 2011 for a controlled drainage system compared to an uncontrolled system (Poole et al., 2013).

Structure Management

To maximize the benefits of CD, users must actively manage the structures throughout the year. Unfortunately, many CD systems that have been installed over the years are not properly managed. Water-control-structure management tables have been developed for your reference as a starting point for fine-tuning management protocols for a specific CD system. These tables were based on years of field-collected data and computer modeling studies to maximize water quality without hurting crop yields. If you have installed or will install a CD structure through a cost-share program, the contractual agreement includes a management table. It is very important that these structures are properly managed year-round to maintain both adequate drainage intensity for crop growth and downstream water-quality benefits.

On average, the NC coastal plain receives about 48 inches of rainfall annually. Roughly 36 inches of water a year is needed to meet the potential evapotranspiration needs of most crops; this means that approximately 12 inches of water is available annually for management and potential conservation within the drainage system to both reduce nutrient export and mitigate drought effect on crops. Typically, dry conditions in North Carolina occur during June through August and vary in frequency, duration, and severity. Unmanaged drainage systems, even when designed to properly remove sufficient water for crop production, can overdrain fields when droughts occur.

A good example of the potential of CD when properly managed was demonstrated between 2008 and 2010. Nineteen producers actively participated in a pilot program using an on-line drainage advisory system developed by the Department of Biological and Agricultural Engineering at North Carolina State University. The advisory system was developed to maximize the yield and water conservation potential of CD on farms. During this time, the water management model DRAINMOD (Skaggs, 1982, 1999; Skaggs et al., 2012) was utilized to give participants site-specific recommendations for riser management. The model predicted higher crop yields for all 19 producers, and an annual water conservation benefit of almost 5 inches on average, which is nearly 10 percent of the average annual rainfall amount for eastern North Carolina. These recommendations were based on historic weather data, soils, and specific drainage system characteristics.

In general, maximum crop performance is typically achieved with water table depths of 18 to 24 inches from the soil surface halfway between ditches or subsurface drain lines. This depth to the water table is most critical during the late vegetative and reproductive periods for most crops. This depth will vary depending on the drainage system characteristics, soil texture, crop type, and growth stage. Ideal water table depths for most sandy soils will be closer to 18 inches, while fine-textured-clay and silty-clay soils will require water table depths of 24 inches or deeper.

Table 1 summarizes suggested average water-control structure settings for various crops throughout the growing season in North Carolina. These values may vary slightly depending on the drainage system characteristics, soil, and cropping practices at a specific location.

| Corn | ||

| Period | Activity | Control Setting from Average Soil Surface (inches) |

|---|---|---|

| Dec. 1 – Mar. 15 | Fallow | 12 – 18 |

| Mar. 15 – May 15 | Tillage/Planting | 24 – 36 |

| May 15 – Aug. 15 | Growth/Maturity | 18 – 24 |

| Aug. 15 – Oct. 15 | Harvest | 24 – 36 |

| Soybean | ||

| Period | Activity | Control Setting from Average Soil Surface (inches) |

|---|---|---|

| Oct. 15 – April 15 | Fallow | 12 – 18 |

| April 15 – May 10 | Tillage/Planting | 24 – 36 |

| May 10 – Oct. 1 | Growth/Maturity | 18 – 24 |

| Oct. 1 – Dec. 1 | Harvest | 24 – 36 |

| Wheat | ||

| Period | Activity | Control Setting from Average Soil Surface (inches) |

|---|---|---|

| Oct. 15 – Dec. 1 | Tillage/Planting | 24 – 36 |

| Dec. 1 – Mar. 1 | Wheat Establishment | 12 – 24 |

| Mar. 1 – Mar. 15 | Side-dressing | 12 – 36 |

| Mar. 15 – June 1 | Growth/Maturity | 18 – 24 |

| June 1 – July 1 | Harvest/Plant Soybean | 24 – 36 |

| Double Crop Soybean | ||

| Period | Activity | Control Setting from Average Soil Surface (inches) |

|---|---|---|

| July 1 – Nov. 1 | Growth/Maturity | 18 – 24 |

| Nov. 1 – Dec. 31 | Harvest | 12 – 36 |

| Jan. 1 – Mar. 15 | Fallow | 12 –18 |

| Cotton | ||

| Period | Activity | Control Setting from Average Soil Surface (inches) |

|---|---|---|

| Dec. 1 – April 5 | Fallow | 12 – 18 |

| April 5 – June 1 | Tillage/Planting | 24 – 36 |

| June 1 – Sept. 1 | Growth/Maturity | 18 – 24 |

| Sept. 1 –Dec. 1 | Harvest | 24 – 36 |

|

||

It is ultimately up to the producer to make decisions concerning CD riser management for specific situations, such as extreme rainfall events or additional field operations. The goal of such decisions should be to maximize water conservation while protecting the crop from the stress caused by excess water. Because the in-field water table will not be precisely the same elevation as the water level at the control structure, it is recommended that one or more shallow monitoring wells be installed in key locations in the field. By closely monitoring these in-field water table depths during the growing season, the operator will be able to adjust riser boards with more confidence. Consider removing boards when forecasts call for large rainfall events if the water level in the monitoring well exceeds a certain water table threshold set by the operator. Normally, 12 to 18 inches from the soil surface is a good starting point for such a threshold.

Summary

Controlled drainage, a practice that is part of the larger toolbox of practices known as drainage water management, is well-suited to eastern North Carolina farms. The practice has long been recognized as an effective BMP for water quality, but often water control structures are not managed properly (if at all). Recent research, however, has documented another impressive benefit of the practice for NC producers that should motivate more active management of their drainage structures. Significant water conservation benefits and higher crop yields may be realized when the systems are properly managed. The increase in crop yields are attributed to increased water availability and an associated increase in nitrogen uptake by the plants (Poole et al., 2013; 2018). The use of CD and the proper management of these systems are truly a win-win for both the producers and the environment.

Year-round management of CD structures is pivotal to achieving higher yields. This is especially true in the months that often include periods of drought. The highest documented yield benefits of the practice have come during water-deficient growing seasons.

For producers with CD systems, manage your structures to maximize both water quality benefits and crop yields. For producers thinking about using this practice in the future, consider the topography and potential layout of new drainage systems prior to installing CD. This is an important step in achieving the best return on your investment. The ultimate goal of any DWM system should be to maximize economic returns.

Researchers are working to develop better management protocols for enhancing crop yields over a wide range of soil types and weather conditions, new water management system designs, and more efficient water systems for North Carolina. In the future, new systems and protocols will be field-tested using new technologies such as automated controls, cellular data transfer, and weather forecast predictions. There is also hope that other DWM systems—such as subirrigation and water capture and reuse—can provide additional ways to minimize drainage water flow and nutrient export, while allowing for possible water reuse for supplemental irrigation.

References

Evans R. O., R. W. Skaggs, and J. W. Gilliam. 1995. Controlled versus conventional drainage effects on water quality. J. Irrig. Drain. Eng., 121(4): 271-276. https://doi.org/10.1061/(ASCE)0733-9437(1995)121:4(271)

Evans, R. O., and R. W. Skaggs. 2004. Development of controlled drainage as a BMP in North Carolina. In R. Cooke (Ed.), Proc. 8th Intl. Symp. on Drainage. St. Joseph, MI: ASAE.

Gilliam, J. W., R. W. Skaggs, and S. B. Weed. 1979. Drainage control to reduce nitrate loss from agricultural fields. Journal of Environmental Quality, 8:137-142.

Poole, C. A., R. W. Skaggs, G. M. Cheschier, M A. Youssef, and C. R. Crozier. 2013. Effects of drainage water management on crop yields in North Carolina. J. Soil Water Cons., 68: 429-437.

Poole, C. A., R. W. Skaggs, G. M. Cheschier, M. A. Youssef, and C. R. Crozier. (2018). Effect of drainage water management on nitrate nitrogen loss to tile drains in North Carolina. Trans. ASABE 61: 233-244.

Liu, Y., M. A. Youssef, G. M. Chescheir, T. Appelboom, C. A. Poole, C. Arellano, and R. W. Skaggs. 2018. Effect of controlled drainage on nitrogen fate and transport for a subsurface drained grass field receiving liquid swine lagoon effluent. Agricultural Water Management. In Review.

Skaggs, R. W. 1982. Field evaluation of a water management simulation model. Trans. ASAE 25:666-674.

Skaggs, R. W. 1999. Drainage simulation models. In R.W. Skaggs and J. van Schilfgaarde (Eds.), Agricultural Drainage (pp. 469-500). Agron. Monogr. 38. Madison, WI: ASA, CSSA, and SSSA.

Skaggs, R.W., M. A. Youssef, and G. M. Chescheir. 2012. DRAINMOD: Model use, calibration and validation. Trans. ASABE 55:1509-1522

Skaggs, R. W., and J. W. Gilliam. 1981. Effect of drainage system design and operation on nitrate transport. Trans. ASAE, 24: 929-934. https://doi.org/10.13031/2013.34366

Acknowledgments

We would like to thank the reviewers for this publication:

Robert O. Evans, Jr., PhD, PE, Professor Emeritus, Biological and Agricultural Engineering, NC State University

Jane Frankenberger, PhD, Professor, Agricultural and Biological Engineering, Purdue University

Chris Hay, PhD, Senior Environmental Scientist, Iowa Soybean Association

Publication date: Sept. 11, 2018

Reviewed/Revised: June 14, 2023

AG-851

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.