This factsheet reviews the movement of nitrogen in concentrated feeding operations for raising swine, and is intended for readers looking for basic background information on animal production systems. The nitrogen dynamics and practices described here are specific to North Carolina, and may not apply to other geographic regions where swine are produced.

Introduction

In North Carolina, most swine are produced in concentrated animal feeding operations (CAFOs). A swine CAFO contains at least 2,500 swine weighing more than 55 pounds. As the nation’s third largest hog producing state, North Carolina has CAFOs across the state, primarily concentrated in the East. These CAFOs produce millions of gallons of manure (urine, feces, and water used in the production process) each year, which are flushed from swine barns to lagoons where manure is stored and treated. Manure contains nutrients and digested organics that require careful management. Swine producers store manure in one or several open-air lagoons on the property that can hold millions of gallons of animal manure. These lagoons allow the flushed manure to separate into settled solids that decompose in the lagoon underneath a liquid layer. The liquid layer contains decomposed dilute organic matter, soluble nitrogen, and phosphorus (Zongliu, 2020). This liquid is typically applied as fertilizer to crop and grass fields, with part of the liquid recycled for use in flushing the barns. In North Carolina, the fields associated with swine farms are typically referred to as “sprayfields” since the liquid is often land-applied using spray irrigation systems. Crops are grown on sprayfields in order to uptake the nutrients contained in the manure. Over 2,227 swine operations rely on this manure management system in North Carolina.

Manure nitrogen is beneficial for crops as fertilizer in controlled amounts, but can be harmful when applied in excess. Developing and following nutrient management plans (NMPs) is required by law for each swine CAFO in North Carolina to ensure manure nitrogen is used beneficially by growing crops (for instance, no excess manure is land-applied). When excess nitrogen is applied, it can accumulate in soils and move downward through the soil (for example, through a leaching process) which causes groundwater pollution. Nitrogen can also travel across the land surface with stormwater runoff, and pollute waterways like lakes and streams. Excess nitrogen contributes to rapid algae growth or toxic algal blooms in surface waters (NC State Extension, 2017). Algal blooms can also lead to fish kills and further disturb aquatic life by disrupting food chains, causing major ecological damage over time. Low concentrations of un-ionized ammonia can cause toxicity in certain fish species leading to additional fish kills. This process can occur in small, local streams and ponds, but has the most drastic effect when contaminated waters flow into larger waterways. Because excess nitrogen can be detrimental to surrounding ecosystems, it is important to understand where nitrogen losses from a farm system can occur.

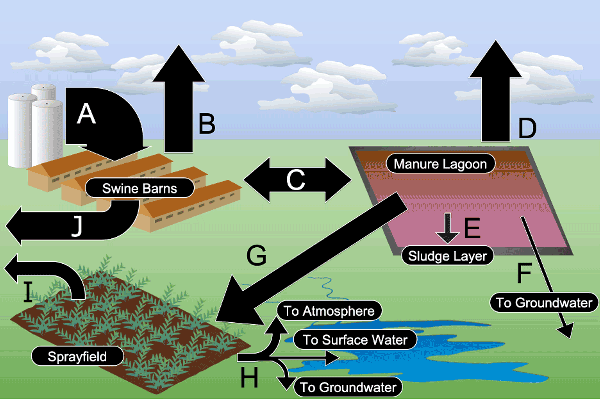

Practices to prevent nitrogen overapplication rely on understanding how nitrogen cycles through a CAFO system and addressing leakages in each stage. The movement of nitrogen in a swine CAFO operation typically falls into general categories of transportation, transformation, or loss to the environment. The factsheet is organized in sections corresponding to key nitrogen flows in a typical swine farm that uses a lagoon-sprayfield manure management system (illustrated in Figure 1). The arrows in Figure 1 represent individual nitrogen flows, with arrow widths drawn to approximate the amount of nitrogen associated with each flow. Nitrogen first enters the swine farm as feed (Figure 1A). Nitrogen is an important swine feed ingredient, but only around 46% of feed nitrogen remains in animals that leave the farm (Figure 1J) (Millet et al., 2018), while the rest is excreted in urine and feces that are flushed to the lagoon (Figure 1C). Some nitrogen is volatilized to the atmosphere from waste in the swine barns (Figure 1B). From the lagoon, a portion of the nitrogen in the manure is volatilized (Figure 1D), some accumulates as sludge (Figure 1E), some seeps to groundwater (Figure 1F), and the rest is applied to crops in sprayfields as fertilizer (Figure 1G). In the sprayfields, some nitrogen is lost during and shortly after manure application (Figure 1H), with up to 30% of applied nitrogen emitted as ammonia during application (Arogo et al, 2002). Another pathway for N loss is downward leaching with drainage to the groundwater (10% to 17% of applied nitrogen)(Liu et al, 2019). The crops take up the remaining nitrogen (around 50% of applied N) and are ultimately harvested, with nitrogen leaving the swine farm as a useful byproduct (Figure 1I).

This factsheet seeks to explain this on-farm cycle of nitrogen and methods of nitrogen movement through a CAFO system, as well as briefly touching on possible methods to reduce unwanted nitrogen loss.

Nitrogen Flows within Swine Farms Using Lagoon-Sprayfield Manure Management Systems

A. Swine Feed to Swine Barn

Swine diets vary depending on the production phase, but the goal is always to help the animals gain weight and stay healthy at minimal cost. Swine rations are formulated to ensure enough energy and amino acids are consumed in their diet. Amino acids are the building blocks for protein, and are the primary source of nitrogen in swine rations. Soybean meal is a common ingredient in swine rations (Niche production, n.d). Soybean meal provides a balance of most essential amino acids that helps swine grow efficiently. Swine gain most weight in the last stage of production, the “growing/finishing” phase, as they become market ready. No matter the age, swine must consume feed and excrete manure. The excrement contains several nutrient-rich components such as protein. Reducing excreted nitrogen can be achieved by improving feed efficiency, balancing types of amino acids in the diet, and optimizing digestibility. Increasing feed digestibility can be achieved by optimizing feed pellet sizes. Reducing crude protein and adding essential amino acids results in a more balanced amino acid profile. Also, adding feed enzymes can help swine digest complex feed ingredients, thereby increasing nutrient availability for animal growth and reducing the nitrogen content of the manure.

B. Swine Barn to Atmosphere

In North Carolina, swine manure sits in pits under swine barns for a variable amount of time (hours to days) and on the barn floor before being flushed into the treatment lagoon. Some of the organic nitrogen in the manure becomes liquid ammonium (NH4+) through hydrolysis and mineralization processes. Ammonium can easily shift to a volatile gaseous form, ammonia (NH3), which is emitted from the barns and from the lagoon. The rate of ammonia production and the amount of ammonia volatilized into the air is influenced by several factors, including the concentration of dissolved ammonium, the pH of the manure, and the average temperature (Liang et. al, 2002). Less than 10% of the nitrogen entering a swine farm through feed will typically be lost through this nitrogen flow (Harper et al, 2014).

Producers can reduce nitrogen losses from the swine barn due to volatilization by implementing a scrubbing/adsorption system to treat exhausted air. Also, removing ammonia from recycled effluent used during the flushing process (for instance, flushing manure into the lagoon) can be effective in reducing barn emissions.

C. Barn to Treatment Lagoon

Using recycled lagoon liquid, manure is flushed from barns into the lagoons on site for treatment and longer-term storage until it can be used effectively as fertilizer. In this process, the manure nitrogen is transported from the barn to the lagoon in pipes, and losses to the environment during this step are negligible.

D. Manure Treatment Lagoon to Atmosphere

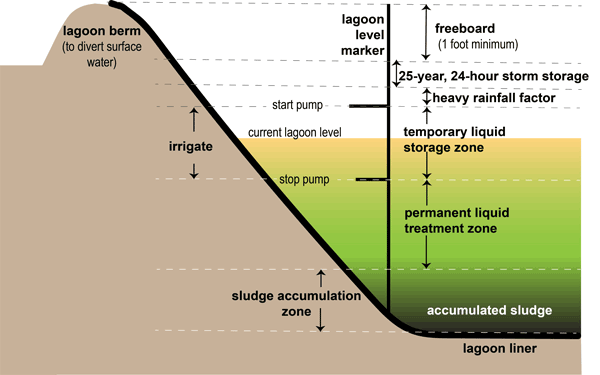

In the lagoon, manure physically settles into layers: a solid layer, referred to as sludge, and a liquid layer, which is further divided into a storage and treatment zone (Figure 2). The treatment process involves microbes breaking down the organic components in the manure into their basic compounds such as carbon dioxide, methane, and ammonia. When in the lagoon, some nitrogen compounds such as ammonia (NH3), nitrogen gas (N2), and nitrous oxide (N2O) undergo volatilization, similar to what was described in Section B. This volatilization moves a significant amount of nitrogen into the atmosphere and is influenced by wind speed, temperature, and the pH of the lagoon. Most of the nitrogen losses on a swine farm occur through this nitrogen flow, with up to 50% of the nitrogen entering a farm through feed leaving via volatilization (Harper et al. 2004; Harper et al. 2014).

There are ways that producers can slow this process and prevent harmful nitrogen emissions of NH3 and N2O from moving into the atmosphere. These processes include technologies installed before the lagoon, or ones added to the lagoon. Examples of pre-lagoon technologies include: [1] segregating urine from feces to prevent feces enzymes from decomposing the urea in the urine to form ammonium and ammonia, and [2] using an ammonia stripping system to capture the urine nitrogen in a salt form. For lagoon nitrogen emissions, potential technologies to reduce nitrogen loss include [3] adding permeable (floating) covers that include adsorption material such as biochar to reduce ammonia release (Dougherty et al, 2017), and [4] installing sealing covers to completely seal off the lagoon and prevent gas release. It is important to note that the last option, impermeable covers, will increase ammonium concentration in flush liquid, which would increase emissions in the barn during the flushing process.

In lagoon systems, another option for mitigating NH3 and N2O losses is adopting the biological processes of nitrification-denitrification. These processes are used to convert manure ammonia by first oxidizing it to nitrates/nitrites (NO3/NO2) (nitrification process), and then removing oxygen molecules to produce atmospheric nitrogen (N2) through denitrification. This process has been successfully tested and installed on swine operations and was found to be effective in reducing ammonia emissions (Vanotti et al,2001; Townsend et al, 2013; Adair et al, 2016).

E. Sludge Deposits in Lagoons

A small fraction of the nitrogen excreted by swine remains in the decomposed solid material, sludge, which settles in the bottom of the lagoon. The sludge accumulates over time and it is recommended to remove sludge periodically (five to 10 years) to maintain lagoon treatment volume and performance. Sludge removal often involves the use of specialized machinery such as dredges or excavators. The dredged sludge can be land applied directly, treated to generate byproducts, or disposed of in landfills. When treated, the resulting byproducts can be used as either soil amendments or substrates for energy production. The energy value of sludge, however, is marginal since microbial activity uses the energy in the manure solids during decomposition. The nitrogen present in the sludge is largely in an organic form that is not readily available to growing plants. Over time, the sludge nitrogen is mineralized and can be lost to the environment through volatilization (Figure 1B, Figure 1D), runoff (Figure 1H), or leaching (Figure 1F). Unlike nitrogen, most of the phosphorus excreted by animals is retained in the sludge. Without careful use of this phosphorus-rich material, sludge can contribute to environmental problems due to runoff of phosphorus and accumulation in freshwater bodies.

Nitrogen losses from land application of dredged sludge can be prevented by ensuring the sludge is well incorporated into the soil to minimize runoff losses. Similarly, sludge nutrients are slow to mineralize and become plant-available. As a result, nutrient plans need to account for sludge nitrogen credits over multiple crop cycles. On some swine farms in North Carolina, the removed sludge is stored in permeable bags to allow it to dewater before land application. In such cases, the bags need to be fully contained and isolated with effluent flowing back into the lagoon. Additional losses can be prevented by adsorption of volatilized nitrogen during sludge drying and composting.

F. Manure Treatment Lagoon to Groundwater

Proper lagoon design should significantly reduce the risk of nitrogen loss to groundwater (by leaching), or surface water (by runoff, see section H below). However, maintenance and management will influence performance. Treatment lagoons are required to have a liner covering the bottom and sides to prevent liquid and sludge from freely seeping into groundwater, limiting nutrient contamination (Figure 2). Liners can be made out of clay found near the site, bentonite clay, or a synthetic material. Each material has benefits and drawbacks, and all require careful installation to minimize seepage rates (USDA, 2016; NC State Extension, 2017).

Other methods to lessen losses at this step are to avoid any punctures in the lagoon liners during routine and maintenance operations, installing drain systems under the lagoon to capture seepage, overflow, spills, and leakages of the lagoon liquid. Monitoring groundwater around the lagoon is helpful to ensure no leakage occurs from the structure and address any leaching that might occur.

G. Manure Treatment Lagoon to Sprayfield and Crop

Manure nutrients should be applied to crops in a manner and time period that they support a growing crop. In North Carolina, the time period for spraying the manure mixture in the treatment lagoon on sprayfield crops spans 30 days before planting up until the harvesting date. Irrigation should be timed to coincide with maximum nitrogen uptake by growing plants. Manure cannot be applied on sprayfields outside of this window without special exceptions. Sprayfield crops are not grown for human consumption but can be grown for animal feed or other non-food purposes. Grasses are commonly grown on sprayfields. Once sprayed, nitrogen in the manure liquid is taken up through plant roots. The amount of nitrogen taken up by the crops depends on the crop type, climate, and soil type. For example, commonly grown bermudagrass and tall fescue both have a nitrogen uptake of 40 to 50 lb Nitrogen/ton (NC State Extension, 2017). The manure liquid acts as a fertilizer, stimulating plant growth and, ideally, increasing yield overall.

H. Sprayfield to Waterways

Manure sprayed onto crops has potential to runoff into waterways. Due to this risk, there are regulations in place that limit the volume of manure that can be applied onto a sprayfield in a 24-hour period, as well as provide a 12 hour gap where no manure can be sprayed before a rainfall event. Excess applied liquid can create runoff into waterways if applied in large volumes, or can make its way into runoff when rainwater picks up nutrients not taken up by crops (NC State Extension, 2017).

In order to reduce the amount of nitrogen going into the local waterways, producers can use certain steps like calibrating spray equipment to ensure precise application rate, using subsurface injection to prevent losses during application, adopting cover crops to minimize losses, using fiber check dams and polyacrylamide (PAM) to avoid organic nitrogen loss, or using impounding structures with vegetation uptake to minimize nitrogen loss form runoff. Relying on manure application methods such as injection can also minimize evaporation and ensure nitrogen is preserved in soil where growing crops can utilize it. Maintaining good record of the manure volume in the lagoon is critical to ensure land application can be planned for beneficial nitrogen use while avoiding risks associated with extreme climate conditions.

I. Crops to Animal Feed

The sprayfield crops that thrived from the manure nitrogen application as fertilizer can be harvested and used as animal feed or fiber. In some cases, the harvested crops will be used as feed within the CAFO system where the crops were produced. However, in most cases, the crop will be processed, sold, and removed from the farm. For example, swine CAFOs growing hay or grasses may sell their harvest to a dairy or beef farm for feed.

J. Swine Biomass to Market

Approximately 46% of the nitrogen consumed by swine supports animal growth and function. Accordingly, some of the nitrogen will leave the farm in the form of swine byproducts, like meat.

Conclusions

A swine farm can house tens of thousands of animals. North Carolina is the country’s third largest hog producer, meaning millions of gallons of manure are produced each year per farm. Swine manure contains large amounts of nitrogen that can be both beneficial and detrimental to the surrounding land. In an animal farm system, nitrogen flows several ways and in varying amounts. Finding ways to efficiently use the nitrogen along with other nutrients found in swine manure makes animal agriculture more efficient and more environmentally sustainable.

Acknowledgments

This work is supported by the Agriculture and Food Research Initiative, Educational Literacy Initiative’s Research and Extension Experiences for Undergraduates grant program (grant no. 2019-67032-29074/project accession no. 1018043) from the USDA National Institute of Food and Agriculture, and USDA Hatch grant, Accession Number 1022103-02800.

Anjel Iriaghomo and Breanna Sorrells are co-first authors of this publication.

References

Adair, C. W., Xu, J., Elliott, J. S., Simmons, W. G., Cavanaugh, M., Vujic, T., and Deshusses, M. A. (2016). “Design and Assessment of an Innovative Swine Waste to Renewable Energy System.” Transactions of the ASABE, 59(5), 1009–1018.

Arogo, J., Westerman, P. W., and Heber, A. J. (2003). “A Review of Ammonia Emissions from Confined Swine Feeding Operations.” Transactions of the ASAE, 46(3), 805.

Bonmatı́, A., and Flotats, X. (2003). “Air Stripping of Ammonia from Pig Slurry: Characterisation and Feasibility as a Pre- or Post-Treatment to Mesophilic Anaerobic Digestion.” Waste Management, 23(3), 261–272.

Dougherty, B., Gray, M., Johnson, M. G., and Kleber, M. (2017). “Can Biochar Covers Reduce Emissions from Manure Lagoons While Capturing Nutrients?” Journal of Environmental Quality, 46(3), 659.

Harper, L. A., Sharpe, R. R., Parkin, T. B., De Visscher, A., Van Cleemput, O., and Byers, F. M. (2004). “Nitrogen Cycling through Swine Production Systems: Ammonia, Dinitrogen, and Nitrous Oxide Emissions.” Journal of Environmental Quality, 33(4), 1189–1201.

Harper, L. A., Weaver, K. H., and De Visscher, A. (2014). “Dinitrogen and Methane Gas Production during the Anaerobic/Anoxic Decomposition of Animal Manure.” Nutrient Cycling in Agroecosystems, 100(1), 53–64.

Integration and Application Network (n.d). Symbols to be used in figures and diagrams. From University of Maryland Center for Environmental Science Integration and Application Network.

Iowa Pork Industry Center. (n.d.). “Niche production.” Retrieved July 29, 2021. the Iowa Pork Industry Center website.

Liang, Z. S., Westerman, P. W., and Arogo, J. (2002). “Modeling Ammonia Emission from Swine Anaerobic Lagoons.” Transactions of the ASABE, 45(3), 787–798. From the American Society of Agricultural and Biological Engineers.

Liu, Y., Youssef, M. A., Chescheir, G. M., Appelboom, T. W., Poole, C. A., Arellano, C., and Skaggs, R. W. (2019). “Effect of Controlled Drainage on Nitrogen Fate and Transport for a Subsurface Drained Grass Field Receiving Liquid Swine Lagoon Effluent.” Agricultural Water Management, 217, 440–451.

Manure Production (Volume & Weights). (n.d.). Retrieved July 28, 2021, from the Manure Production (Volume & Weights) section of the Nutrient Management Website.

Millet, S., Aluwé, M., Van den Broeke, A., Leen, F., De Boever, J., and De Campeneere, S. (2018). “Pork Production with Maximal Nitrogen Efficiency.” Animal, 12(5), 1060–1067. From the Animal Journal.

NC State Extension. (2017). Certification Training for Operators of Animal Waste Management Systems: Type B. AG-538-B. Retrieved July 28, 2021.

NC State University. (n.d.). “Manure Nutrients.” Retrieved July 28, 2021, from the NC State University Nutrient Management website.

Owusu-Twum, M. Y., and Sharara, M. A. (2020). “Sludge Management in Anaerobic Swine Lagoons: A Review.” Journal of Environmental Management, 271, 110949.

Philippe, F.-X., Cabaraux, J.-F., and Nicks, B. (2011). Ammonia Emissions from Pig Houses: Influencing Factors and Mitigation Techniques. Agriculture, Ecosystems & Environment, 141(3), 245–260. From the Agriculture, Ecosystems & Environment Journal.

Townsend, D. A., Paulsen, B. A., and Wells, W. J. (2003). “Large Scale Nitrification/Denitrification of Swine Waste.” In Animal, Agricultural and Food Processing Wastes-IX (p. 1). American Society of Agricultural and Biological Engineers.

United States Department of Agriculture, National Resources Conservation Service. (2016). “Conservation Practice Standard: Pond Sealing or Lining—Compacted Soil Treatment, Code 520” (PDF).

Vanotti, M. B., Rice, J. M., Hunt, P. G., Humenik, F. J., Ellison, A. Q., Baird, C. A., and Szogi, A. A. (2001, October). “Evaluation of Polymer Solids Separation, Nitrification-Denitrification, and Soluble Phosphorus Removal System for Treating Swine Manure.” In Proc. Intl. Symposium Addressing Animal Production and Environment (pp. 3–5).

Zhu, Y., Yang, J., and Wang, L. (2009). “Experimental, Numerical and Sensitive Analysis of Nitrogen Dynamics in Soils Irrigated with Treated Sewage.” Science in China Series E: Technological Sciences, 52(11), 3279–3286.

Zongliu and Zongliu. (2020, July 02). “Proper Lagoon Management to Reduce Odor and Excessive Sludge Accumulation.” Retrieved July 28, 2021, from Texas Animal Manure Management Issues.

Publication date: June 13, 2022

AG-927

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.