Overview

- Maintenance of Irrigation Equipment

- Off-Season Storage Procedures

- Hard Hose Travelers

- Sprinklers/Big Guns

- Pumps

- Diesel Engines

- Electric Motors

Maintenance of Irrigation Equipment

- Ensures longevity of the equipment.

- Minimizes unexpected downtime.

- Ensures that effluent can be applied when environmental conditions are optimal.

- Reduces the risk of waste discharges that may result in environmental damage and possible fines.

Off-Season Storage Procedures

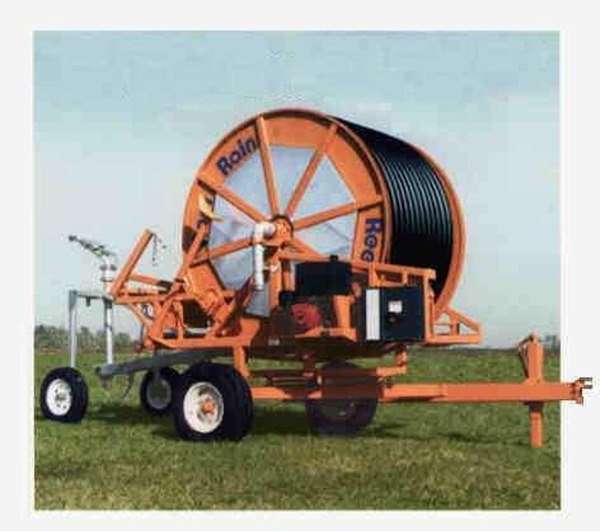

Hard Hose Travelers (Figure 1)

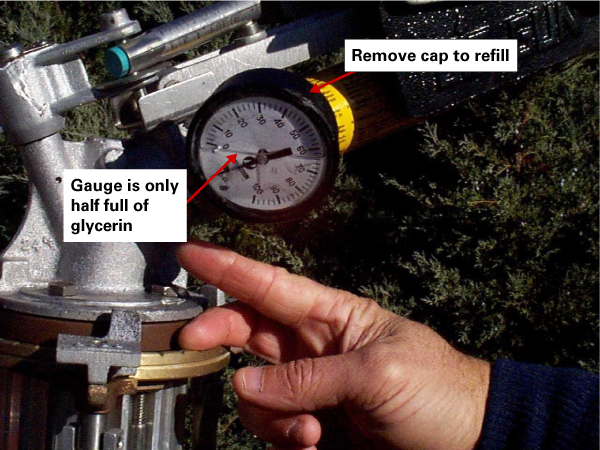

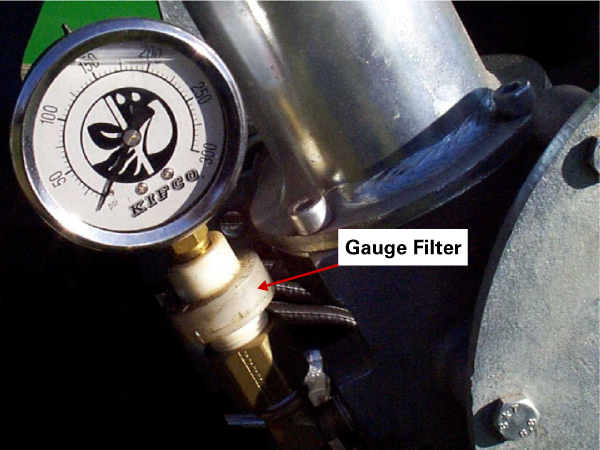

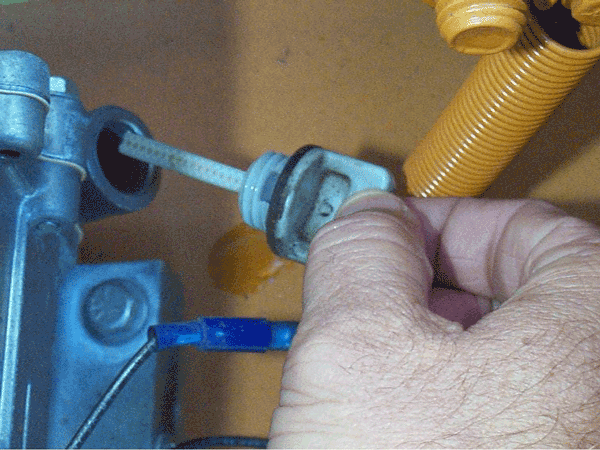

- Ensure the pressure gauges are operating properly (Figure 2).

- Lubricate travelers according to the manufacturer's recommendation (Figure 5).

- Inspect the nozzles and rings for wear (Figure 6). Use calipers to measure the rings.

- Inspect the intake lines for holes and wear (Figure 7).

- If possible, store travelers under a roof and keep them dry and clean (Figure 8).

- If available, use an air "blow out" cap to blow water from the hose before storing (Figure 9).

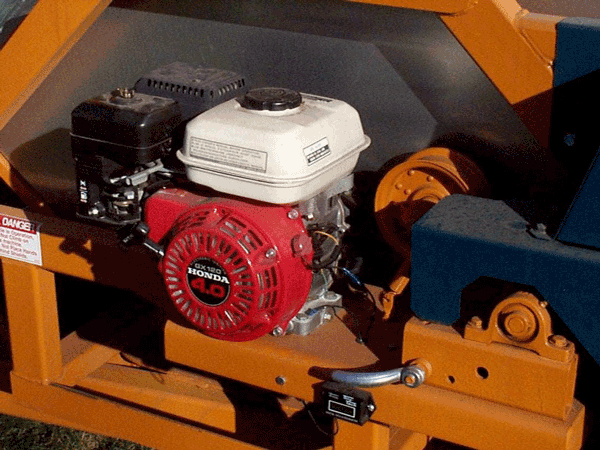

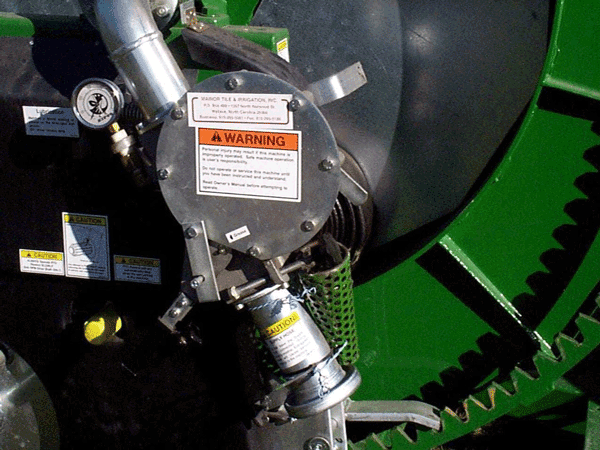

Engine Drive Travelers (Figure 10).

- Check the engine oil daily (Figure 11).

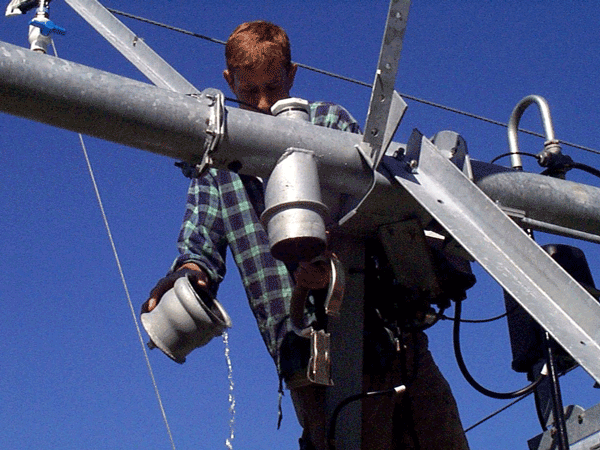

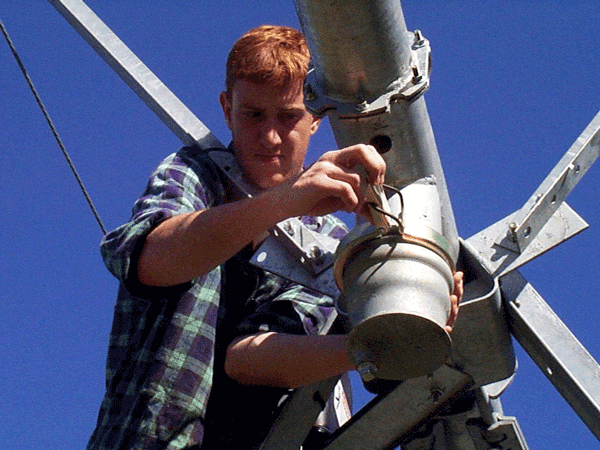

Turbine Drive Travelers (Figure 12)

Turbine Drives

- If installed, remove the drain plug before storing.

- Use a strainer in the intake line if solids are greater than 2% (Figure 13).

- Keep all chains lubricated and inspect belts for wear (Figure 14).

- Keep the turbine properly greased (Figure 15).

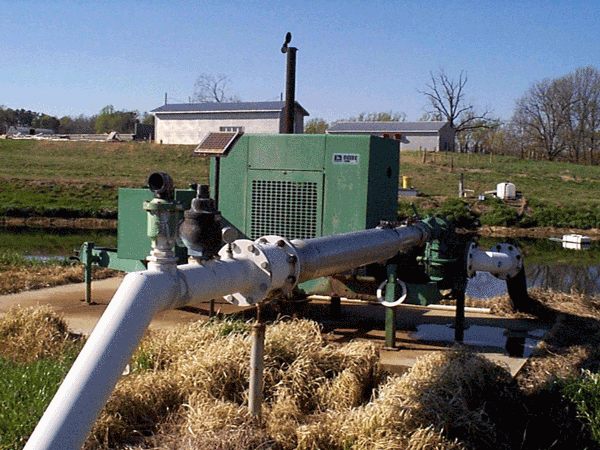

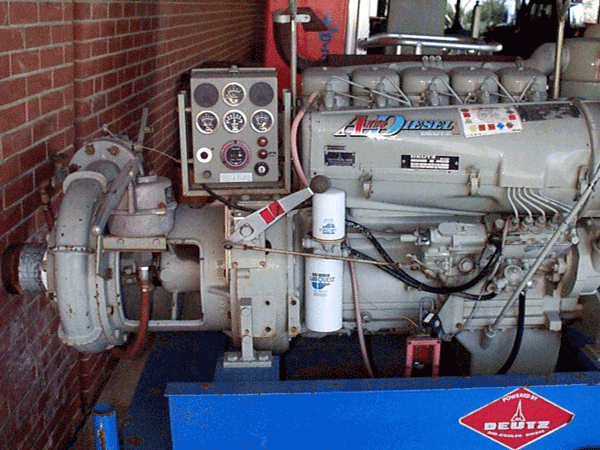

Diesel Engine Pumps (Figure 16)

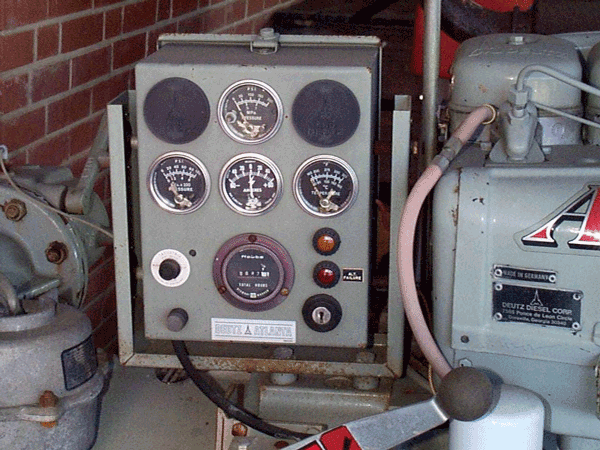

- Ensure that all gauges are operating properly (Figure 17).

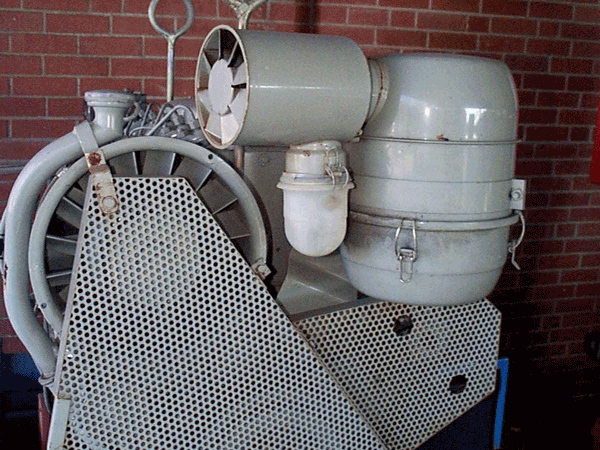

- Follow the operation and maintenance procedures for servicing the air filtering system (Figure 18).

- Check with the service dealer before servicing the timing or turbocharger (Figure 19).

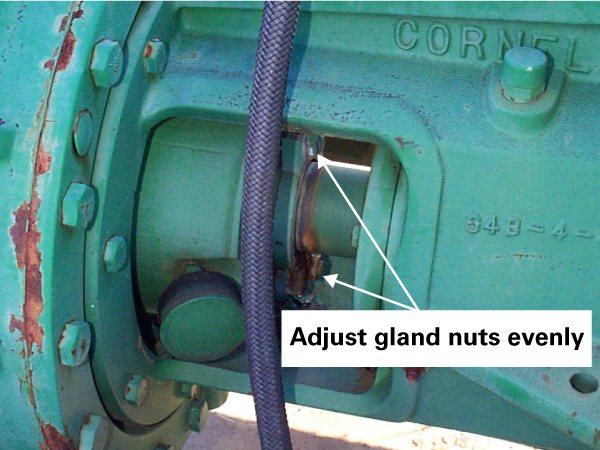

- Check the packing seal drip rate. Most packing seals need to drip approximately 40-45 drips per minute (Figure 20).

- Check the chain connections before each irrigation event (Figure 21).

- Check the connections and seals to minimize excessive leaks (Figure 22).

- Ensure the air and pressure relief valves are free of debris (Figure 23).

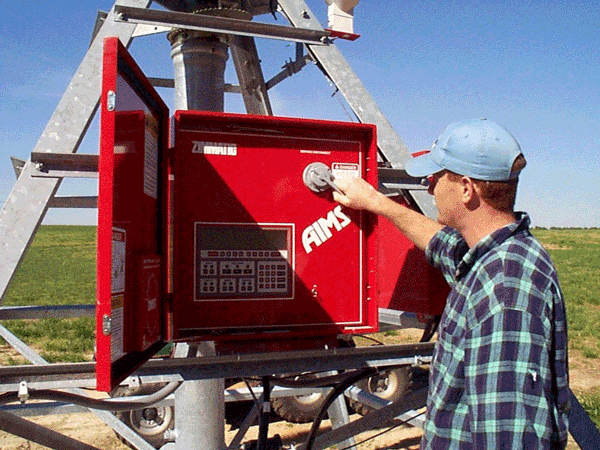

Pivots and Linears (Figure 24)

- As with all electrical equipment, ensure the power is turned off before performing any maintenance or service checks (Figure 25).

- Drain and refill the wheel oil annually or every 1,000 hours of operation (Figure 26).

- After validating the rotation speed, manually check the emergency-stop or auto reverse devices or switches (Figure 27).

- Drain the sand/grit traps periodically. Monitor for excess accumulation and nozzle wear (Figure 28).

- Check all seals, flanges, and couplings for leaks (Figure 29).

- Look for sprinkler wear on the splash plates and wobbler heads. Remove any hair or other debris (Figure 30).

Publication date: July 5, 2022

AG-602

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.

This publication printed on: March 27, 2025