Abstract

Screw press separators can divide a single by-product stream into a solid and liquid stream to improve handling and management. These processing systems are commonly used in manure handling systems but can be used for management of many organic streams. For example, a wet digestion system that accepts food waste may also integrate the technology following anaerobic digestion. Regardless of the application, screw press separators are more efficient in removing solids from manure slurry streams (greater than four percent total solids or dry matter content) than with more dilute liquid manure streams. The systems are known to improve manure handling as well as reduce environmental impacts of livestock systems.

A pdf version of this publication is available from The Learning Store, Division of Extension, University of Wisconsin-Madison.

Manure Processing Series Partners

- University of Wisconsin Platteville, School of Agriculture

- NC State University, College of Agriculture and Life Sciences

- Texas A&M, Agrilife Extension

- University of Idaho, Department of Soil and Water Systems

Introduction

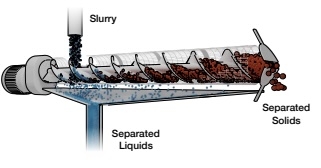

Screw press separators can be used to separate manure into a solid and liquid fraction. Liquid or slurry manure enters the system that produces two output streams. The output streams consist of separated solids that have a higher solid content than the original manure and separated liquids that have a lower solid content than the original manure (Figure 1). These two streams, separated solids and liquids, can be managed separately to increase operational efficiencies, develop end products with higher value, decrease costs for handling and storage, and reduce environmental impacts. However, to take advantage of these benefits the system needs effective management.

Screw press separators are widely used in manure processing systems to separate manure. They are commonly located on-farm at the location where the manure is produced. In a recent survey of Wisconsin dairy farmers, solid liquid separation was the most used manure processing system after sand separation (Aguirre-Villegas and Larson 2017). It was also found that they are installed at large or permitted operations. Screw press separators can be used to capture separated solids for use as animal bedding. After separating, solids are commonly dried before use as animal bedding. Separated solids can also be composted, field applied, or further processed to make other manure-based products. These other manure-based products can include pellets or biochar (a product of pyrolysis). Screw press separation is a common first processing step in manure systems that have multiple processing units. In addition to removing solids, screw press separators produce a second stream with lower solids content, or separated liquids. Separated liquids can be more easily transported for field application using pumps and/or irrigation equipment that can reduce hauling costs.

Screw press separators can be used as a stand-alone piece of equipment (Figure 2), or in a system with other processing components. They can be used in parallel with other screw press separators to increase capacity or in series with other technologies. Each screw press can handle a defined volume of manure each day. If the manure requiring processing exceeds the capacity of one screw press separator, several screw press separators can be used in parallel to increase the handling capacity. The systems run side by side producing solids and liquid streams that are each combined with the same products from each separator in the system. Separators can also be used in series with other equipment, such as other separator types, anaerobic digesters, and sand separation systems. In some instances, screw press separators can be used before other separators. For example, the separated solids from a screw press separator may then go through a belt press to remove additional moisture. Or the separated liquids may go through an inclined screen to remove additional small organic particles from the liquid stream.

The order of the components is selected to achieve the characteristics of the final streams that are desired. Screw press separators are commonly used after a digester to separate the digestate, or effluent from the digester. But in some cases, the separator can come before the digester with either the separated solid or liquid stream then going into the digester system. Removing liquid from the manure will reduce the size of the digester as there is less volume to process. A smaller digester reduces capital costs. In other cases, solids are removed to reduce the digester hydraulic retention time, or time the manure remains in the digester. This can also decrease overall system size. Screw press separator system integration requires a clear understanding of technology goals and performance to integrate the screw press separator at the most beneficial point in the manure system.

Technology Basics

Screw press separators are commonly used for manure but can be used in any organic stream. For example, a wet digestion system that accepts food waste may also integrate the technology following anaerobic digestion. Regardless of the application, screw press separators are more efficient in removing solids from manure slurry streams (greater than four percent total solids or dry matter content) than with more dilute liquid manure streams.

The influent stream enters the separator where plates exert pressure and liquids are then forced through a screen. The screen has small holes that allow liquids to exit and be collected while keeping solids inside the screen so they can be collected separately. The screen size openings determine the particle size of solids collected. A smaller screen size will capture smaller particles thereby increasing the solids separated. However, with smaller particles collected the moisture content of the solid stream usually increases. As the screen size increases, retention of solids decreases as does the moisture content.

Performance

Screw press separators have separated liquid streams with marginal reductions in the liquid total solids content. The separated solid streams have a dry matter content around 30%. However, the separated solids and liquid stream characteristics are variable based on the inputs and system design.

Separation system performance can be defined by their separation efficiency. Separation efficiency is measured by the removal of solids and nutrients from the incoming manure stream. An efficient separator results in separated solids with a high proportion of solid and nutrient content. Efficiency varies widely and depends on many factors, such as separator type and design, manure type, manure consistency, total solids content, and flow rates.

In a recent study of separators in Wisconsin dairy farms, screw press separators had different separation indexes for different manure constituents (Table 1) (AguirreVillegas, Larson, and Sharara 2019). The separation efficiency for solids was much greater than for nutrients, where nitrogen and potassium removal in the solids was low (as expected as they are more soluble). This agrees with a larger study conducted in Europe where screw press separators had low separation efficiencies for many parameters (Guilayn et al. 2019).

| Constituent | Separation Index |

|---|---|

|

Total Solids |

0.40 |

|

Volatile Solids |

0.42 |

|

Total Nitrogen |

0.11 |

|

Ammonia |

0.003 |

|

Total Phosphorus |

0.25 |

|

Total Potassium |

0.07 |

Cost

A screw press separator can cost between $50,000 and $150,000. However, installation costs can be greater as the system requires other components to integrate in the manure systems. Separators require manure handling and transfer systems to store manure prior to entering the separator, and to transport and handle the products once separated (Figure 3). In addition, separators typically require a space protected from the environment. If located in a building, it requires significant ventilation to manage human health concerns from the gases released from manure. The gases can cause asphyxiation or pose other human health risks such as toxicity from hydrogen sulfide. While the installation and operation may pose costs, the solid and liquid streams may be land spread more cost effectively than unprocessed manure.

Environmental Benefits

Installing a manure screw press separator can reduce greenhouse gas and ammonia emissions. The emissions are reduced after processing during manure storage and after land application when compared to manure handling without processing. A separator reduces greenhouse gas emissions through multiple pathways. First, methane emissions from liquid manure storage are reduced since the compounds responsible for these emissions (volatile solids) are separated along with the solid stream (Aguirre-Villegas, Larson, and Reinemann 2014). Second, if manure solids are stored, the aerated conditions that exist during this storage limit the emissions of methane. Third, the separation process removes the fibrous and large pieces of organic material from the manure liquid fraction, which prevents a natural crust from forming on top of the stored liquid. A natural crust can create aerobic conditions that promote nitrate production near the surface. Nitrate can then be converted to nitrous oxide, a greenhouse gas that is 264 times more potent in warming the Earth than carbon dioxide (Rotz et al. 2015). Without a natural crust storage conditions are anaerobic, which will prevent nitrate from forming, thus reducing nitrous oxide emissions from liquid manure storage. Greenhouse gas emissions from dairy manure management can be reduced by 19% when a screw press separator for solid-liquid separation is used (Aguirre-Villegas and Larson 2017; Aguirre-Villegas, Larson, and Sharara 2019). While there is an increase in fossil greenhouse gas emissions from electricity consumption when the energy matrix is based on fossil fuels (e.g. coal), the increment is negligible when compared to the manure emission reductions.

Ammonia emissions from storage of the liquid stream can increase after solid-liquid separation due to the lack of a natural crust on top of the storage (Rotz et al. 2015). This crust constitutes a barrier for wind that promotes nitrogen volatilization (gas lost as ammonia). Despite the increase during storage, total ammonia emissions from manure management in systems with solid-liquid separation remain the same as in systems without separation since the ammonia emissions after application are reduced (Aguirre-Villegas, Larson, and Reinemann 2014). This reduction is attributed to a more effective infiltration of inorganic nitrogen into the soil since the organic material in the liquid manure stream is decreased during separation. Some practices to reduce ammonia emissions include installing a manure storage cover and injecting manure into the soil instead of applying it on the surface.

Separating manure can also have water quality benefits as the solid manure can be used in environmentally sensitive areas to reduce runoff and infiltration. Applying manure with a higher solids content can reduce losses. In addition, the separated liquids have a higher infiltration rate when applied that can also reduce post-application runoff.

Limitation to Installation

Screw press separators are a mature technology, and many are installed and operational. The main limitation to the installation is capital cost. The capital costs may be too high to implement particularly at smaller livestock facilities.

References

Aguirre-Villegas, H.A. and R.A Larson. 2017. “Evaluating greenhouse gas emissions from dairy manure management practices using survey data and lifecycle tools.”Journal of Cleaner Production 143:169-179. https://doi.org/10.1016/j.jclepro.2016.12.133

Aguirre-Villegas, H.A., R.A. Larson, and D.J. Reinemann. 2014. “From waste-to-worth: Energy, emissions, and nutrient implications of manure processing pathways.” Biofuels, Bioproducts and Biorefining 8:770-793. https://doi.org/10.1002/bbb.1496

Aguirre-Villegas, H.A., R.A. Larson, and M. Sharara. 2019. “Anaerobic digestion, solid-liquid separation, and drying of dairy manure: Measuring constituents and modeling emission.” Science of the Total Environment 696:134059. https://doi.org/10.1016/j.scitotenv.2019.134059

Guilayn, F., J. Jimenez, M. Rouez, M. Crest, and D. Patureau. 2019. “Digestate mechanical separation: Efficiency profiles based on Anaerobic Digestion feedstock and equipment choice.” Bioresource Technology 274:180-189. https://doi.org/10.1016/j.biortech.2018.11.090

Rotz, C.A., M.S. Corson, D.S. Chianese, S.D. Hafner, R. Jarvis, and C.U. Coiner. 2015. “The integrated farm system model (IFSM): Reference manual, v. 4.2”, Pasture Systems and Watershed Management Research Unit, Agricultural Research Service, United States Department of Agriculture (USDA). University Park, PA.

© 2021 by the Board of Regents of the University of Wisconsin System doing business as the University of Wisconsin–Madison Division of Extension. All rights reserved.

Division of Extension publications are subject to peer review.

Reviewers: Sandra Stuttgen is the agriculture agent for Taylor County; Jerome Clark is the agriculture educator for Chippewa County; and Aerica Bjurstrom is the agriculture educator for Kewaunee County. All are with the University of Wisconsin-Madison Division of Extension.

University of Wisconsin–Madison Division of Extension, in cooperation with the U.S. Department of Agriculture and Wisconsin counties, publishes this information to further the purpose of the May 8 and June 30, 1914, Acts of Congress. An EEO/AA employer, University of Wisconsin–Madison Division of Extension provides equal opportunities in employment and programming, including Title VI, Title IX, the Americans with Disabilities Act (ADA), and Section 504 of the Rehabilitation Act requirements. For communicative accommodations in languages other than English, please contact oaic@extension.wisc.edu. Persons with disabilities who require alternative means for communication of program information (braille, large print, audiotape, etc.) should contact Heather Lipinski Stelljes.

This publication is available from your UW Extension office or from Division of Extension Publishing.

Screw Press Separation of Manure (A4192-002/AG-919-02)

1-10-2021

Publication date: Jan. 10, 2021

Reviewed/Revised: Dec. 23, 2025

AG-919-02

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.