Abstract

Including sloped screens for solid-liquid manure separation can have positive impacts on manure management systems by reducing lagoon sludge buildup, recycling manure fiber, and mitigating fibers. This fact sheet reviews the key indices used to evaluate the effectiveness, throughput, and other key factors, along with a summary of the cost and benefits of adopting sloped screen separation in multi-stage manure treatment systems.

A pdf version of this publication is available from The Learning Store, Division of Extension, University of Wisconsin-Madison.

Manure Processing Series Partners

- University of Wisconsin Platteville, School of Agriculture

- NC State University, College of Agriculture and Life Sciences

- Texas A&M, Agrilife Extension

- University of Idaho, Department of Soil and Water Systems

Technology Basics

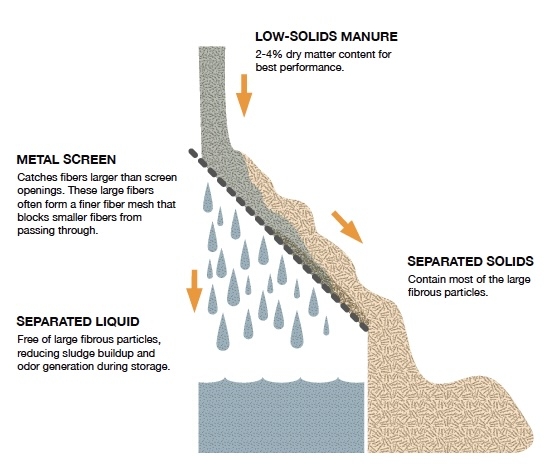

Sloped screen separators can remove solids from liquid manure at high rates. The manure in this system flows as a sheet over bar slats or a wedge-wire screen. The liquid passes through the slats or screen and solids are collected and slide down the sloped separator (Figure 1). The liquid that flows through is usually pumped to secondary separations, lagoons, and/or other manure storages. The separated solids accumulate on the lower part of the screen and then slide off periodically.

These separated solids can be directly deposited on a pad or stacked by a conveyor or an auger.

Sloped screen separation is the preferred separation method when manure has a dry matter content between 2 – 4%. Sloped screen separators are recommended for flushed manure from a freestall barn, wastewater from milking centers, and flushed swine manure from a recharge pit. Sloped screen separators are applicable when the dry matter content is greater than 5% and they are less effective than sedimentation or centrifuge when the dry matter content is less than 2%.

The screen catches almost all large fibrous particles (size greater than 0.02 – 0.1 inches, depending on the screen) from liquid manure (2 – 4% dry matter). Without separation, these large particles would enter the manure storage and take a long time to biologically degrade. By removing large particles, a sloped screen separator can reduce sludge buildup and mitigates odor generation from manure storage. At the same time, this operation saves labor and energy costs associated with manure agitation, removal from storage, and land application (cost saving from land application assumed the screened solids will be reused as bedding).

One major disadvantage of sloped screen separation is cleaning labor. Solids stuck in the screen are generally removed manually, unless the separator has an auto-clean feature (Figure 1). Another disadvantage of screen separation is its inability to remove very small solids. When the manure from a barn is flushed by lagoon water rich in fine solids, it will return these solids to the manure system.

Performance

The effectiveness and throughput capacity of a sloped screen separator is determined by the screen opening size and the rate at which manure is fed to the screen. A typical screen opening size is 0.02 - 0.1 inches. A finer screen reduces the throughput rate and the separated solids contain more dry matter. The maximum feeding rate that can be achieved depends on factors such as the screen size, opening size, and manure consistency. When the feeding rate is too high, a substantial amount of liquid can be seen to overshoot the screen. In this case, the bypass flow – liquid and solids that do not pass through the screen – lowers the separation efficiency by carrying solids into the liquid stream without separation.

A sloped screen separator retains large fibrous materials on one side of the screen, and the composition and quantity of these solids determine the capture rate of nutrients. Typical capture rates of sloped screen separators with 0.060 – 0.066 inch openings are shown in Table 1. There are often large variations in the capture rates (even with a similar type of screen) due to on-farm management factors such as the amount of organic bedding used and whether lagoon water is used to flush the manure.

|

Constituent |

Amount removed by screen (%) |

|---|---|

|

Total Solids |

49 – 61 |

|

Volatile Solids |

50 – 63 |

|

Ammonium-N |

8 – 46 |

|

Organic-N |

19 – 52 |

|

TKN |

17 – 49 |

|

Total Phosphorus |

11 – 53 |

A sloped screen separator is also capable of removing a portion of small particles. The separated solids usually contain a significant portion of manure, bedding, and waste feed particles smaller than the size of the screen openings. They are mainly trapped in a mesh formed by solids built up on the top of the screen (Figure 2). A sloped screen separator can generally catch more small particles with the naturally formed mesh or large particles compared with screens using mechanical pressure or scraping action, which would force small particles through the screens.

A sloped screen separator can capture more solids from fresh manure, especially when it is stored less than one day (Kunz et al., 2009). After extended storage, especially during warm weather, the manure solids degrade and become weaker and more dissolvable. Large organic fibers and particles may disintegrate into smaller ones and then pass through the screen. Solid-liquid separation is recommended as soon as possible after manure is collected, to achieve higher efficiency in removal rates.

Application in Multi-Stage Treatment

A sloped screen separator is one of the simplest separation technologies offering a high throughput rate. It is often used in series with other solid-liquid separation technologies, such as screw press, roller press, or centrifuge to provide high solid and nutrient removal rates while maintaining a high throughput rate. These downstream processes greatly benefit from the first-stage screen separation, because the total intake volume is reduced and foreign materials harmful to the equipment are removed by the screen. These systems yield separated solids with a dry matter content often greater than 20%.

In addition, sloped screen separation can also be combined with sedimentation and/or coagulation/flocculation (e.g., by polyacrylamide polymer or liquid aluminum sulfate) to achieve maximized removal of total solids, volatile solids, total phosphorus, TKN, and organic nitrogen. These two-stage systems are usually more efficient in reducing nutrients in the separated liquid stream, which can aid farms to achieve their wastewater and nutrient management plans.

References

Aguirre-Villegas, H.A., R.A. Larson, and M.A. Sharara. 2019. “Anaerobic digestion, solid-liquid separation, and drying of dairy manure: Measuring constituents and modeling emission.” Science of the total environment, 696: 134059. ↲

Chastain J.P., M.B. Vanotti, and M.M. Wingfield. 2001. “Effectiveness of liquid–solid separation for treatment of flushed dairy manure: a case study.” Applied Engineering in Agriculture, 17(3): 343–354. ↲

Fulhage, C.D., and J. A. Hoehne. 1998. “Performance of a screen separator for flushed dairy manure.” In Proc. of the Fourth Intl. Dairy Housing Conf., ed. J. P. Chastain, 28–30 Jan., St. Louis, Mo., 130–135. St. Joseph, MI: ASAE. ↲

Kunz A., R.L.R. Steinmetz, M.A. Ramme, and A. Coldebella. 2009. “Effect of storage time on swine manure solid separation efficiency by screening.” Bioresource Technology, 100, 5, 1815–1818. ↲

Zhang, R. H., and P. W. Westerman. 1997. “Solid–liquid separation of animal manure for odor control and nutrient management.” Applied Engineering in Agriculture, 13, 5, 657–664. ↲

© 2021 by the Board of Regents of the University of Wisconsin System doing business as the University of Wisconsin–Madison Division of Extension. All rights reserved.

Division of Extension publications are subject to peer review.

Reviewers: Kevin Janni is a Professor for the Bioproducts and Biosystems Engineering Department at the University of Minnesota; Jun Zhu is a Professor for Biological and Agricultural Engineering at the University of Arkansas; Tyler Barzee is an Assistant Professor for the Biosystems Engineering Department at University of Kentucky.

University of Wisconsin–Madison Division of Extension, in cooperation with the U.S. Department of Agriculture and Wisconsin counties, publishes this information to further the purpose of the May 8 and June 30, 1914, Acts of Congress. An EEO/AA employer, University of Wisconsin–Madison Division of Extension provides equal opportunities in employment and programming, including Title VI, Title IX, the Americans with Disabilities Act (ADA), and Section 504 of the Rehabilitation Act requirements. For communicative accommodations in languages other than English, please contact oaic@extension.wisc.edu. Persons with disabilities who require alternative means for communication of program information (braille, large print, audiotape, etc.) should contact Heather Lipinski Stelljes at heather.stelljes@wisc.edu.

This publication is available from your county Extension office or from Division of Extension Publishing.

Sloped Screen Separator for Manure (A4192-004/AG-919-04)

Publication date: Jan. 12, 2021

Reviewed/Revised: Nov. 19, 2025

AG-919-04

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.