Vinegar

FDA considers the following to be satisfactory guidelines for the labeling of vinegars:

Natural vinegars as they come from the generators normally contain in excess of 4 grams of acetic acid per 100 mL. When vinegar is diluted with water, the label must bear a statement such as "diluted with water to _______ percent acid strength", with the blank filled with the actual percent of acetic acid - in no case should it be less than 4 percent. Each of the varieties of vinegar listed below should contain 4 grams of acetic acid per 100 mL.(20C).

VINEGARS:

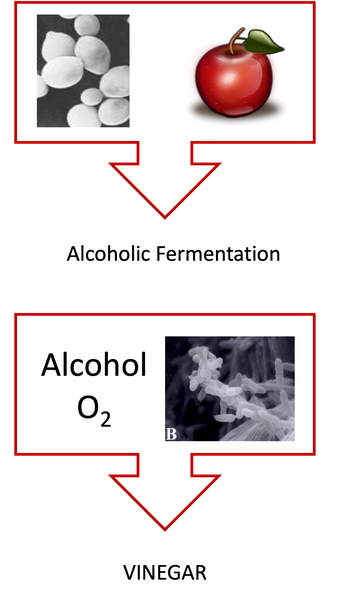

- VINEGAR, CIDER VINEGAR, APPLE VINEGAR. The product made by the alcoholic and subsequent acetous fermentations of the juice of apples.

- WINE VINEGAR, GRAPE VINEGAR. The product made by the alcoholic and subsequent acetous fermentations of the juice of grapes.

- MALT VINEGAR. The product made by the alcoholic and subsequent acetous fermentations, without distillation, of an infusion of barley malt or cereals whose starch has been converted by malt.

- SUGAR VINEGAR. The product made by the alcoholic and subsequent acetous fermentations of sugar sirup, molasses, or refiner's sirup.

- GLUCOSE VINEGAR. The product made by the alcoholic and subsequent acetous fermentations of a solution of glucose. It is dextrorotatory.

- SPIRIT VINEGAR, DISTILLED VINEGAR, GRAIN VINEGAR. The product made by the acetous fermentation of dilute distilled alcohol.

- VINEGAR, MADE FROM A MIXTURE OF SPIRIT VINEGAR AND CIDER VINEGAR. The product should be labeled as a blend of the products with the product names in order of predominance. This labeling is applicable to a similar product made by acetous fermentation of a mixture of alcohol and cider stock.

- VINEGAR MADE FROM DRIED APPLES, APPLE CORES OR APPLE PEELS. Vinegar made from dried apples, apple cores or apple peels should be labeled as "vinegar made from ______," where the blank is filled in with the name of the apple product(s) used as the source of fermented material.

Different countries may use other starting materials, for example:

- Continental Europe- grape wines

- Great Britain- malt

- Hawaii and the Far East- pineapple

- USA- apple

Acetic Acid (Fermentation?)

- 2CH3CH2OH + O2 = 2CH3COOH + 2H20

- Ethanol 92 mg/mol

- Acetic acid 120 g/mol

- Theoretical yield (120/96) × 100 - 130%

- Practical yield ~ 120%

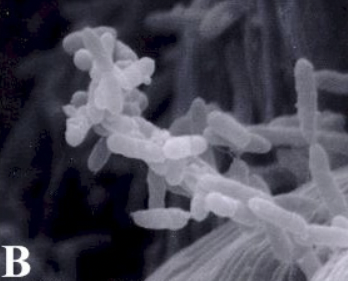

Acetic Acid Bacteria

- Obligatory aerobic

- Nitrogen-fixing bacteria

- Known for producing acid as a result of metabolic processes

- Acetobacter aceti (Figure 2).

Fermented Vinegar

- Made from good alcohol (wine, beer) that is fermented using acetic bacteria that convert alcohol to acetic acid.

- The process can be controlled by using great care in cleanliness and introducing chosen yeast (wine) and bacteria (vinegar) to obtain good quality every time.

Methods of Making Vinegar

SLOW

- Home making

- Orleans process. ----> Better flavor of vinegar

RAPID

- The generator system

- Submerged fermentation system (bubble method)

Wine Vinegar

- Wine that usually contains 11-12% alcohol must be diluted to 5.5-7% alcohol before using it to make vinegar

- Vinegar should contain at least 5% acetic acid as required for preserving and pickling

Making Wine Vinegar

- Utensils

- Use glass, stainless steel, and enamel. Vinegar leaches molecules from iron and aluminum

- Sanitize utensils

- Everything that will touch vinegar should be sanitized. Soak everything for 20 minutes in a solution of 2 tablespoons chlorine laundry bleach to 1 gallon of water

- Dilute wine to 5.5-7% alcohol with water

- Fill sterilized containers about 2/3 full

- Add bacteria cultures

- Leaving wine exposed to air may sometimes start the process, but it is very risky because some other organisms may grow

- It is recommended to order pure cultures of bacteria, sometimes called the mother of vinegar

- They can be purchased in any store that supplies wine-making equipment. It usually comes as a clear liquid in a jar (Figure 3)

- Cover the container with a cloth to keep the insects out while allowing air to freely reach the stock (Figure 4 and Figure 5)

- Two factors require special attention when making vinegar at home:

- Oxygen Supply

- Temperature

- Between 80-85°F is ideal

- Low or fluctuating temperatures slow the process

- High temperatures will kill bacteria

- Formation of the Film

- Living bacteria are in the liquid

- They can be used to start a new batch of vinegar, so it is not necessary to purchase new starter bacteria

- Full fermentation will take 3-4 weeks

Preserving Vinegar

- Filter vinegar through a layer of cheesecloth to remove the formed film-mother of vinegar before pasteurization

- Heat vinegar before pouring it into sterilized bottles

- Bottle and place in a hot water bath

- In both cases, the temperature of the vinegar must reach at least 140°F and should not exceed 160°F and should be held at that temperature for at least 30 minutes

- Vinegar will stay in excellent condition almost indefinitely if pasteurized and unopened. Once opened, mold contamination can occur and be visibly growing in vinegar.

Aging Vinegar

- Vinegar has a strong, sharp bite when it is just made

- It becomes mellow when aged

- It usually lasts six months or longer when stored at a cool, steady temperature (50-60°F) (Figure 8)

- This undisturbed rest also allows suspended solids to fall, making the vinegar clear and bright

- Once the vinegar is ready, it should be kept away from oxygen because acetic acid could be converted into water and carbon dioxide

Flavored Vinegar

- Flavoring can be added to homemade vinegar just before bottling

- Some additives can include: garlic, ginger, or any combination of dried, fresh herbs

- Place flavoring material in a small cheesecloth bag and suspend in vinegar until the desired strength is reached

- It will take approximately four days, except for garlic, which takes only one day

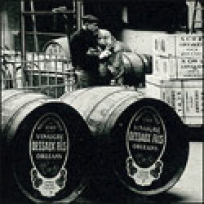

Orleans Process

- Wine or cider is fermented in wooden barrels or covered vats.

- There are screened air vents in the container's top part

- Vents are screened to prevent fruit flies.

- A starter culture is put into the container, and the fermentation is continued until the certification is complete.

- About 3/4 of the vinegar will be drawn off and replaced with fresh wine or other fermentable liquid.

- The process will repeat itself if quality vinegar can still be produced.

- This process is very slow (several weeks) and is usually done in small batches (Figure 9, Figure 10, and Figure 11).

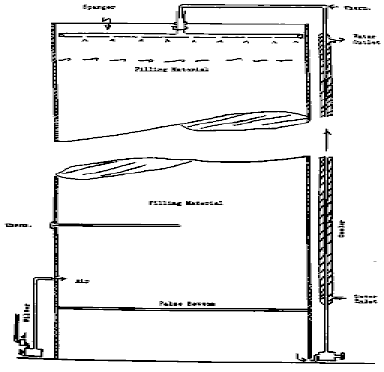

Rapid-generator Process (Schutzenbach)

- Fermentation is done in a container that consists of two chambers.

- The larger (upper) chamber is packed with solid materials almost to the top (wood shavings, corncobs, etc.) (bacteria attach to it).

- The upper chamber is separated from the lower chamber by a screen.

- Air is injected and blown upward through the screen and the solid materials, and the air escapes through the top.

- The fermenting liquids are distributed evenly over the top of the material and allowed to percolate through the material.

- The resulting liquid is pumped back to the top and recirculated until the alcohol content is reduced to 1/2 percent.

- The vinegar is drawn off, and fresh alcoholic solution is added.

Submerged Culture Fermentation (Bubbling)

- First was developed during World War II for the production of penicillin

- Tiny bubbles of air are passed through the solution of ethanol

- Agitated by propellers, dispersing cells of acetic acid bacteria

Essentials for Vinegar Generator

- Must provide for the introduction of fresh substrate without disturbing the content of alcohol or the surface growth

- Must provide easy sampling for titration

- Must protect system from contamination

- Must have means of temperature control

Rate of Acetic Acid Production

- The inherent capacity of Acetobacter aceti to convert alcohol to acetic acid

- The amount of ethyl alcohol (6-8% optimal, 12% tolerated)

- The temperature (80°F optimal, 68-96°F range)

- The amount of aeration of surface area of the growth material

Publication date: July 28, 2022

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.