Introduction

Agricultural, industrial, and municipal wastes, when used properly, can provide much-needed plant nutrients for farmers, landscapers, and home gardeners. Analysis of a waste product is essential for determining its proper use as a fertilizer, liming material, or soil amendment. By determining the product’s amounts of nutrients, levels of some metals, and liming potential, users of these materials can make informed decisions about how much of a waste product to apply.

This factsheet clarifies the importance of waste analysis and describes the procedures for taking reliable samples and submitting them to the Agronomic Services Division of the North Carolina Department of Agriculture & Consumer Services (NCDA&CS).

North Carolina is one of the top livestock-producing states in the United States. In 2017, North Carolina ranked number two in swine production, with 9 million head; number two in turkey production, with 32.5 million head; and number two in poultry production, with 831 million head of broilers and 376 million head of layers (USDA-NASS 2019). These facilities are a source of nutrient-rich byproducts, which are often used to fertilize North Carolina crops.

Animal-producing farms are not the only source of soil amendments that have fertilizer or liming value. Agricultural and food producers, paper manufacturers, and municipalities all generate a variety of waste products. For example, municipalities use centralized wastewater treatment facilities to biologically digest human waste, which produces semisolid residual material known as “biosolids.” Municipalities also accumulate a tremendous volume of yard waste that can be processed into a variety of mulch and compost products. Crop residues (for example, cotton gin residues, tobacco stems, and peanut hulls), food processing byproducts (for example, brewery mash, kitchen scraps, and egg shells), or almost any carbonaceous material may be re-purposed as the starting feedstock in composting operations. These waste materials can then be converted into a marketable agricultural product. The paper industry also generates paper fiber byproducts that can be a significant source of calcium in the form of calcium sulfate (gypsum) or calcium carbonate (lime) in soil amendments. These waste products must be managed differently, depending on each product’s source, nutrient and liming characteristics, and intended use.

As landfill space became increasingly limited in the 1980s, North Carolina’s environmental laws evolved to favor a reduce-reuse-recycle policy. The goal was to drastically reduce the volume of organic materials flowing into landfills, particularly because there were alternative uses for the materials. Waste producers were forced to seek alternative disposal sites or potential recycling opportunities. Land application in accordance with best management practices became the preferred alternative, and it remains so today. Waste products are applied to cropland, pastures, and forests because they contain nutrients or liming materials beneficial to plant growth. Before land application, some materials are composted to reduce volume, improve uniformity, or alter nutrient availability.

Regardless of the source of waste, its intermediate handling, or its final treatment, waste should be analyzed for nutrient content, liming value, and several other important properties that help assess its suitability as a soil amendment. For example, sampling and analysis of animal wastes are required by law for farms with more than 250 head of swine, 100 head of cattle, or 30,000 turkeys or chickens. The law stipulates that manure must be sampled and analyzed within 60 days of land application. This requirement is intended to ensure that land-application rates match the nutrient needs of the crop receiving the waste. Likewise, application of waste materials from sources other than animals should be coupled with an analysis of the nutrient and liming value in the material and a recent soil test specifying the nutrient and liming requirement for the crop.

There is considerable variation of nutrient concentrations and liming values in organic waste products. For example, different batches of compost rarely have the same nutrient value because of differences in the starting feedstocks. The same is true for manures. Changes in feed additives and ration formulation during animal production can drastically alter the nutrient value of the resulting manure. Likewise, the amount of rain falling on an anaerobic treatment lagoon can have a significant dilution effect on swine manure. When management decisions are made without waste analysis information, even well-intentioned users can underapply or overapply waste, thus affecting plant growth and yield or endangering the environment.

Laboratory analysis gives the user of the material the information needed to determine the application rate that meets the specific crop nutritional requirements for each site. Animal wastes analyzed by the NCDA&CS Agronomic Services Division vary widely in nutrient content and liming values (Table 1).

| Manure Type | Nutrient | Minimum | Maximum | Median |

|---|---|---|---|---|

| Broiler house litter (lb/ton) | Nitrogen | 2.0 | 106 | 52 |

| Phosphate (P2O5) | 2.5 | 127 | 44 | |

| Potash (K2O) | 0.6 | 114 | 57 | |

| Turkey house litter (lb/ton) | Nitrogen | 1.9 | 105 | 39 |

| Phosphate (P2O5) | 0.3 | 108 | 50 | |

| Potash (K2O) | 0.1 | 93 | 35 | |

| Swine lagoon effluent (lb/1,000 gal) | Nitrogen | 0.0 | 11.0 | 2.6 |

| Phosphate (P2O5) | 0.001 | 276 | 0.7 | |

| Potash (K2O) | 0.004 | 117 | 5.5 | |

| Dairy liquid slurry (lb/1,000 gal) | Nitrogen | 0.2 | 116 | 16.7 |

| Phosphate (P2O5) | 0.1 | 154 | 9.1 | |

| Potash (K2O) | 0.1 | 204 | 15.4 |

| Byproduct | Minimum | Maximum | Median |

|---|---|---|---|

| Compost, plant-based | 1 | 830 | 15 |

| Wood ash | 1 | 77 | 6 |

| Paper fibers | 1 | 1,733 | 6 |

| Biosolids | 1 | 676 | 4 |

Note that in some cases the maximum and minimum values for nitrogen, phosphate, potash, and agricultural lime equivalence (ALE) differ by more than a thousandfold (Tables 1 and 2). These numbers demonstrate that average nutrient estimates from the tables are not adequate guides for the safe, efficient use of waste materials.

Growers who apply compost or waste to land without testing it are guessing: Are they supplying plants with adequate nutrients? Are they building up excess nutrients that may ultimately move to streams or groundwater? Are they changing the soil pH to levels that will not support plant production? Are they applying heavy metals at levels that may be toxic to plants and permanently alter soil productivity?

To get answers to these questions, growers should always have waste materials analyzed by a qualified laboratory. The information in the analysis report helps determine the best application rates, reducing potential environmental damage and resulting in optimum growth and yield.

How Do I Take a Waste Sample?

Proper sampling is key to reliable waste analysis. Although laboratory procedures are extremely accurate, they have little value if the samples fail to represent the waste product. Laboratory analyses are performed on a portion of the sample submitted that is as small as 0.01 pound (0.5 gram) for solid materials or less than a tablespoon (10 milliliters) for liquid materials.

Waste samples submitted to a laboratory should represent the average composition of the material that will be applied to the field. Reliable samples typically consist of a composite of subsamples collected from at least 10 locations. Precise sampling methods vary according to the type of waste.

Never use galvanized metal containers for collecting, mixing, or storing waste samples because of the risk of sample contamination from zinc in the protective surface coating.

Liquid waste sampling and preparation

Collect and prepare the samples as follows:

- Place sample in a 12-ounce plastic bottle. Used water or soda bottles are acceptable but should not be washed with detergent. Glass is not acceptable because it is breakable and may contain contaminants.

- Fill the container only three-fourths full to allow for expansion caused by the release of gases from the waste material.

- Seal tightly.

- Refrigerate samples that cannot be shipped on the day they are collected. This will minimize chemical reactions and pressure buildup from gases. Samples should be stored no longer than one week and should never be frozen.

- Label the sample containers to match the sample identifier (ID) included on the Sample Information Form.

Collect specific types of liquid waste as follows:

Lagoon liquid sampling. If the surface liquid in the lagoon is the only component being pumped, there is no need to premix it. Growers with two-stage systems should collect samples from the lagoon that is to be pumped.

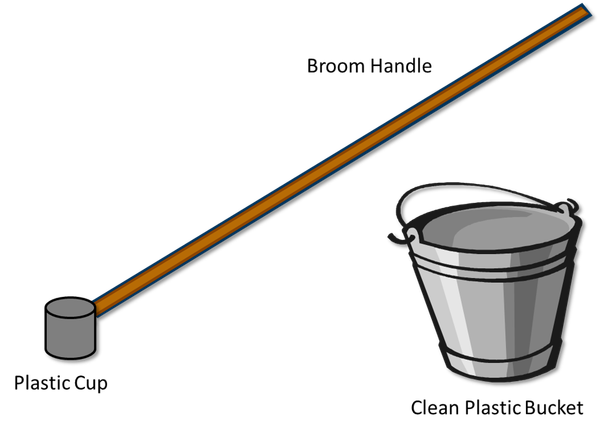

Using a plastic container like the one shown in Figure 1, collect subsamples that measure half a pint to 1 pint each from 10 to 12 sites around the lagoon. Collect the subsamples at least 6 feet from the edge of the lagoon, at a depth of about 1 foot. Oxygen transfer near the surface of anaerobic lagoons often alters the chemistry of the solution, making surface samples less representative than deeper samples. Avoid collecting floating debris and scum. Deposit the collected subsamples in a plastic container and mix them thoroughly. Fill a plastic container three-fourths full with the mixed material, seal the container, and send it to the laboratory for analysis.

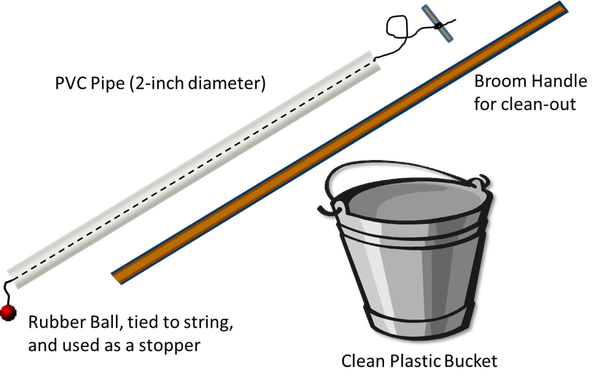

Liquid slurry sampling. Waste materials to be applied as slurry (a mixture of surface liquid and bottom semisolids) from a pit or storage basin should be agitated prior to sampling. Collect subsamples from 10 to 12 areas around the pit or basin, and deposit them in a plastic container. Figure 2 shows a sampling device for collecting slurry. After inserting the PVC pipe into the pit, pull the rubber ball into the pipe to create suction and collect the subsample.

You can also use an 8- to 10-foot section of plastic pipe that is one-half to three-fourths of an inch in diameter. Extend the pipe into the pit and press your thumb over the end to form an air lock. Remove the pipe from the waste, position the end of the pipe over the collection container, and release the air lock to deposit the waste in the container. Mix the collected subsamples thoroughly. Fill a plastic container three-fourths full with the mixed material, seal the container, and submit it to the laboratory for analysis. Do not use additional water to rinse the sample into the container, because doing so dilutes the mixture and distorts nutrient evaluations.

Solid waste sampling and preparation

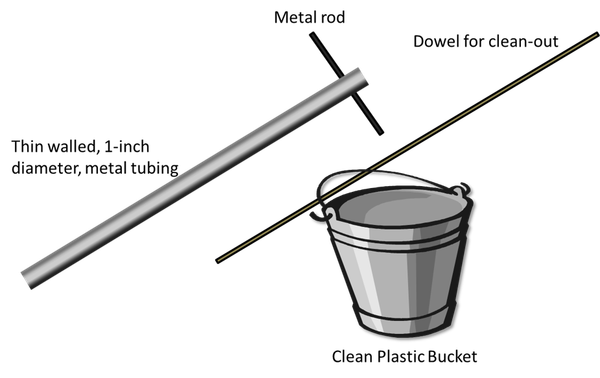

Solid waste samples submitted for analysis should represent the average moisture content of the waste. Figure 3 shows an illustration of a device for collecting solid waste.

Collect and prepare the samples as follows:

- Label a closable plastic sample bag to match the sample submission form.

- Place a 12- to 14-ounce sample in the sample bag.

- Seal the bag tightly.

- Refrigerate samples that cannot be shipped on the day they are collected. This will minimize chemical reactions and loss of moisture. Samples should be stored no longer than one week and should never be frozen.

Collect specific types of solid waste as follows:

Poultry in-house manure sampling. Nutrient concentrations vary widely in poultry litter, both from house to house and within each house. If waste application will correspond to individual houses, collect a separate sample from each.

Collect in-house subsamples from 10 to 12 locations. Each subsample should extend from the top of the accumulated waste to the bottom, assuming a whole-house cleanout. Samples taken around waterers, feeders, and brooders should be proportionate to the spaces these areas occupy in the house. Mix the subsamples thoroughly in a plastic container or bucket. Place approximately 1 pint of this mixture into a labeled plastic container or bag, seal the container, and submit it to the laboratory for analysis.

Poultry below-house manure sampling. In a high-rise system, manure is deposited below the poultry house. If the system is properly managed, the manure should be fairly uniform in moisture and appearance.

Collect 10 to 12 subsamples from the storage area. If manure in certain areas differs in appearance from manure in other areas, take subsamples proportionate to the size and number of these areas.

For example, if 10% of the manure differs from the bulk pile, then 10% of the total sample should be taken from this area. Mix the subsamples thoroughly in a labeled plastic container. Place approximately 1 pint of this mixture in a plastic container or bag, seal the container, and submit it to the laboratory for analysis.

Stockpiled litter. When waste is stockpiled for longer than 15 days, North Carolina General Statutes require that it be stored under cover. The stockpiled waste sample should be collected and analyzed within 60 days of the land application event, but preferably as close to the time of application as is practical. When stockpiled waste is left uncovered, rainfall leaches water-soluble nutrients out of it, and nitrogenous gases escape from the surface. Therefore, the weathered exterior of uncovered waste may not accurately represent the composition of the majority of the material, making it essential to collect subsamples from within the pile and not from the exterior.

Collect subsamples from stockpiled waste to a depth of at least 18 inches, from at least 10 locations. Mix the subsamples thoroughly in a plastic container or bucket. Place approximately 1 pint of this mixture into a labeled plastic container or bag, seal the container, and submit it to the laboratory for analysis.

Surface-scraped waste. Surface-scraped and piled materials should be treated like stockpiled litter. Follow the same procedures for taking samples. Ideally, surface-scraped materials should be protected from the weather unless they are used immediately.

Composted waste. Ideally, composted waste should be stored under cover on an impervious surface. Although nutrients are somewhat stabilized in these materials, some nutrients can leach out during rains. When composted waste is left unprotected, samples should be submitted to the laboratory before the material is applied each time (it may also be collected and submitted the day of application). Sampling procedures are the same as those described for stockpiled litter.

Who Can Analyze My Waste Sample?

The NCDA&CS Agronomic Services Division analyzes wastes, interprets analytical results, and provides management recommendations for use of the waste material. The fee per sample is $8 for North Carolina residents and $25 for submissions from out of state. Additional fees may be charged for certain requested tests. For example, the ALE test costs an extra $10 per sample and is listed as CCE (calcium carbonate equivalency) on the submission form. The test for concentrations of inorganic nitrogen (N) in the nitrate-nitrogen (NO3-N) and ammonia-nitrogen (NH4-N) forms costs $10. Clients can also order molybdenum (Mo) testing for $2 and a heavy metals suite (arsenic, lead, nickel, chromium, selenium, and cadmium) for $20. The samples must be accompanied by a completed Waste Sample Form. These forms are also available from your local Cooperative Extension center or from your NCDA&CS Regional Agronomist. Make checks payable to NCDA&CS.

Directions for filling out the Waste Sample Form are printed on the form. To get the most value from your waste analysis, fill out the form completely and accurately. Contact your local N.C. Cooperative Extension center or NCDA&CS Regional Agronomist if you need assistance. Be sure that all the samples are labeled with your name and sample ID. This is especially important when submitting several samples at once.

Private laboratories also provide some of these services, and their fees vary. A good analytical service should always determine the concentrations of essential plant nutrients, including nitrogen, phosphorus, potassium, calcium, magnesium, sulfur, iron, manganese, zinc, copper, and boron. Analyses of certain municipal and industrial wastes should also include tests for heavy metals such as nickel, cadmium, and lead, as well as elements such as sodium and chlorine. For products or materials suspected of having liming characteristics, the CCE should also be determined.

What Does My Waste Analysis Report Tell Me?

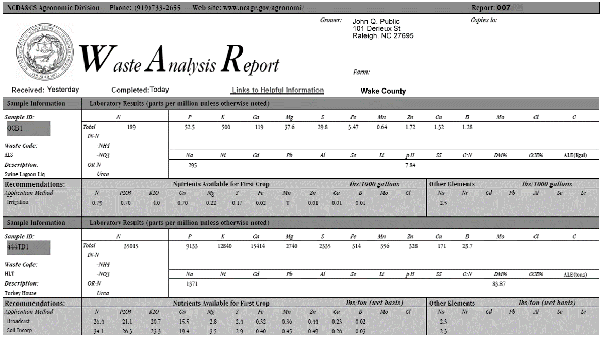

Waste analysis reports provided by the NCDA&CS Agronomic Services Division list concentrations of 11 plant nutrients (nitrogen, phosphorus, potassium, calcium, magnesium, sulfur, iron, manganese, zinc, copper, and boron), sodium, and aluminum. Total nutrient concentrations are reported in parts per million (ppm) on a dry-weight basis for solid wastes and on an as-received basis for liquid wastes in the top panel of the waste analysis report. Plant available nutrients are reported as lb/ton or lb/1,000 gal on an as-received basis in the bottom panel of the report (Figure 4).

Plant-available nutrients

Unlike inorganic fertilizers that become plant available once dissolved, organic plant nutrients are not readily available for plant uptake and must first be mineralized. Organic nutrients are bound in large, complex organic molecules (for example, carbohydrates and proteins) that are not in the chemical forms conducive to plant uptake. During mineralization, soil bacteria decompose these organic molecules, breaking the carbon bonds surrounding the nutrients and releasing the nutrients into their inorganic, mineral form. Thus, the most useful information on a waste analysis report is a prediction of the nutrients available for uptake by the first crop. While the availability of all plant nutrients is subject to mineralization to varying degrees, only nitrogen is reported with an availability estimate. All other nutrients are reported as being 100% available. Nitrogen availability is calculated based on a predicted mineralization rate dependent on the application method. For example, application methods that increase soil contact with the material and reduce nitrogen loss through ammonia volatilization, such as soil injection or incorporation, are predicted to have faster and higher nitrogen availability than surface application methods such as irrigation and broadcasting. Of the total nitrogen in the material, 40% to 60% is predicted to be released in the first year, with most of the release occurring in the first month. Thus, growers should apply wastes near the time when the plants require nutrients. The remaining nutrients gradually become available over the next several months. Nutrients unavailable for the first crop are released or mineralized into plant-available forms over many years. If waste is repeatedly applied over a number of years to soils that do not readily leach, it is possible for nutrients, particularly phosphorus, zinc, and copper, to accumulate in high — even harmful — quantities.

Nutrient availability cannot be determined with 100% accuracy. Many variables — such as the waste type, carbon-to-nitrogen (C:N) ratio, and soil characteristics (texture, moisture, temperature, and aeration) — influence the breakdown of the waste material and nutrient loss. NCDA&CS waste analysis reports provide a realistic but conservative estimation of nutrient availability based on waste type and application method.

To determine the proper waste application rate to meet a specific crop’s nutrient requirements, base your calculations on the nutrient levels listed in the report as “available for the first crop.” For the availability prediction to be reliable, you must correctly identify the type of waste and the application method on the Waste Sample Form submitted to the laboratory.

Agricultural lime equivalent

Sometimes materials that are applied to the land for their nutrient content also have the ability to raise soil pH. For waste materials suspected of having liming effect, such as wood ash, lime-stabilized biosolids, or even many composts, growers should request a CCE determination (Figure 5). The CCE can be used to compare waste materials to agricultural lime in terms of their effectiveness in neutralizing soil acidity. The ALE, which is calculated from the CCE, equates the amount of the waste product that would have to be applied to have the same liming potential as agricultural lime with 90% CCE. For example, if a solid material has an ALE of 5, then 5 tons of that material have the same liming effect as 1 ton of agricultural-grade lime. The lower the ALE value, the stronger the waste material is as a liming source.

Products that may have valuable lime potential often provide less magnesium than dolomitic lime, so users should be aware that they might have to supplement with magnesium, especially when applying waste to sandy soils.

Although particle size of a liming material is not a part of the test for ALE, users should recognize that particle size influences reactivity and spreadability, which are important considerations in evaluating the suitability of materials as lime substitutes.

Note: For materials that may have a liming value, it is critical that growers determine the ALE of materials before soil application. Basing application rates of material with significant liming ability on the nitrogen, phosphorus, or potassium concentrations rather than the ALE can lead to excessively high soil pH and negative impacts on agricultural productivity.

Record Keeping and Monitoring

Those who use waste materials as fertilizer or for liming should keep records of waste reports, application rates, and soil test reports for each application site. You should also take plant samples to evaluate your nutrient management program, identify corrective actions for current crops, and plan improvements for future crops, especially if you are experiencing crop issues. If you are operating a farm with a waste management system permitted by the state of North Carolina, you should review your permit conditions for any additional record keeping requirements.

Where waste products have been applied regularly for years, growers should also monitor buildup of soil-test levels of metals such as zinc and copper that can affect long-term soil productivity. For sites where municipal and industrial wastes are located, nickel, cadmium, lead, selenium, chromium, arsenic, and molybdenum should also be monitored.

Acknowledgments

This publication is a revision of an earlier version. The authors would like to thank D. Crouse, D. Hardy, C. Hudak-Wise, J. Hudyncia, D. Osmond, J. Smyth, J. Spencer, R. Vick, N. Woolard, J. Barker, B. Cleveland, and J.P. Zublena for their earlier contributions.

References

United States Department of Agriculture, National Agricultural Statistics Service (USDA-NASS). 2019. North Carolina’s Rank in U.S. Agriculture — 2018. United States Department of Agriculture, National Agricultural Statistics Service, North Carolina Field Office. Raleigh, NC. Accessed March 23, 2020.

Publication date: June 10, 2021

AG-439-33

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.