Understanding and Managing Animal Food Safety Hazards

New food safety regulations, especially the Food Safety Modernization Act of 2011 (FSMA), require animal feed and ingredient processing facilities to evaluate their ingredients and processes for the presence of hazards that could impact food safety. In this new series from the NC State Animal Food Safety program, we will explore:

-

different hazards that could be present in animal food ingredients and products, and

-

how consumers and processors can protect their animals and products from these potential hazards.

It’s important for those responsible for the implementation of food safety programs (Preventive Controls Qualified Individuals) to be aware of food safety hazards that could be present in their ingredients, products and facility.

What Are Aflatoxins?

Aflatoxins are part of a more general category of naturally occurring chemical food safety hazards called mycotoxins. Mycotoxins are toxic chemical compounds produced from mold. The specific type of mycotoxin produced depends on the species of mold it comes from.

Aflatoxins, produced by Aspergillus flavus, are among the most concerning of the mycotoxins because of the wide impact they can have on human and animal health. Aflatoxins cannot be seen by the naked eye on ingredients or food products. Depending on the species and age of an animal, consuming aflatoxins in food can cause a wide range of health consequences.

Aflatoxins and other food safety hazards are particularly dangerous for animals because animals generally follow a single diet. In contrast, humans tend to eat a variety of foods from different sources. In pets and livestock, toxins or other food safety hazards can accumulate over time, creating more serious health consequences or death.

Animal food producers should also be aware that some mycotoxins, such as aflatoxin, can be passed through dairy feed into milk that is consumed by humans. Many human foods, such as milk, corn and peanuts are tested for mycotoxins, but it’s important to mitigate them as early as possible to prevent illnesses or food waste.

How Can Aflatoxins Impact Animal Health?

Aflatoxicosis, or aflatoxin poisoning, is an illness caused by ingesting aflatoxins.

In livestock and poultry production, young and immature animals, such as

-

chickens and ducks that are less than 8 weeks old,

-

turkeys less than 12 weeks old,

-

goat, sheep and pigs less than 4 months old, and

-

cattle and equine less than 6 months old,

are most susceptible to adverse effects of aflatoxicosis.

Livestock, horses and poultry that experience acute aflatoxicosis may exhibit symptoms such as

-

generalized hemorrhage,

-

bloody diarrhea, and

-

death in 1-3 days.

Aflatoxin toxicity may lead to reduced feed intake, reduced weight gain, liver damage, jaundice and eventually death.

Pets can also get aflatoxicosis. In pets, aflatoxicosis symptoms include

-

sluggishness,

-

loss of appetite,

-

vomiting, and

-

jaundice, and/or diarrhea, as well as asymptomatic liver damage.

FDA Aflatoxin Guidelines

The U.S. Food and Drug Administration (FDA) currently enforces aflatoxin levels in animal food. Just as aflatoxicosis can impact animals based on their species and production class, the aflatoxin action levels reflect the intended use of the feed products as such.

|

Intended Use |

Animal Food and Animal Food Ingredient |

Action Level |

|---|---|---|

|

Finishing (i.e. feedlot) beef cattle |

Corn and peanut products |

300 ppb |

|

Beef cattle, swine or poultry (regardless of age or breeding status) |

Cottonseed meal |

300 ppb |

|

Finishing swine of 100 pounds or greater |

Corn and peanut products |

200 ppb |

|

Breeding beef cattle, breeding swine or mature poultry |

Corn and peanut products |

100 ppb |

|

Immature animals |

Corn, peanut products, and other animal food and food ingredients, but excluding cottonseed meal |

20 ppb |

|

Pets (dogs, cats, rabbits, etc.) of all ages |

Corn, peanut products, cottonseed meal, and other food ingredients and complete pet food |

20 ppb |

|

Dairy animals and other animal species (including wildlife), or other uses not specified in this table; or, when the intended use is not known |

Corn, peanut products, cottonseed meal, and other animal food and food ingredients |

20 ppb |

Source: FDA Compliance Policy Guide Sec. 638.100 Action Levels for Aflatoxins in Animal Food

Aflatoxin Mitigation

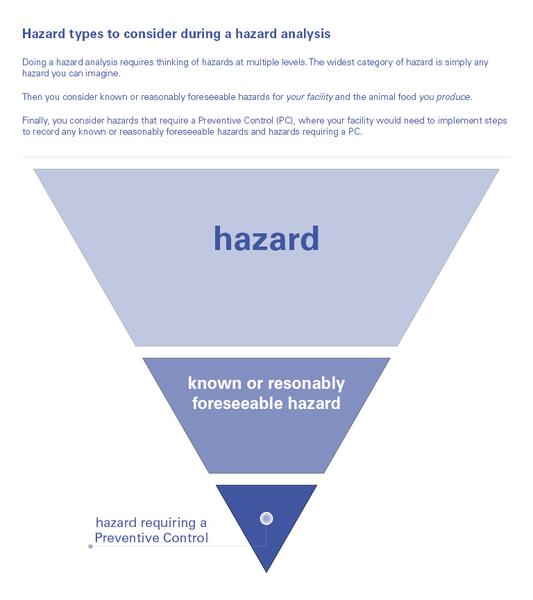

Animal food producers should have a testing program for aflatoxins in place if this is a hazard that is known or reasonably foreseeable (Figure 1) in their incoming ingredients and animal food.

A known or reasonably foreseeable hazard is something that is likely to be present in an ingredient or product that could cause illness or injury to humans or animals.

There are many hazards that could cause illness or injury to humans or animals, but it is up to each facility to assess which ones are likely to be present in their products and have programs or controls in place to prevent them from causing illness or injury.

There are two ways to monitor aflatoxins in a facility:

-

have an in-house testing program in place for incoming ingredients, or

-

collect samples of incoming ingredients to be sent to an offsite lab for testing.

TIP: it’s not recommended to use techniques such as “blacklighting” grains to monitor aflatoxin or other mycotoxin levels. Blacklights cannot measure actual levels of mycotoxins in the ingredients of products.

There are other ways to mitigate the hazard of aflatoxins in a facility. In addition to testing procedures, it is important to have a robust quality assurance program that could include:

-

a supplier approval program;

One way of managing new and existing suppliers is to design a testing program around your supplier approval program. If you have an existing supplier with consistently high quality products and little to no quality issues, you may decide to take composite samples of their incoming ingredients and test less frequently. On the other hand, if you have a new supplier, you may want to test every load for a set amount of time until you have built a relationship and are confident in the quality of their product. Should your monitoring program show that there is an issue with a load or tested ingredient, be prepared to conduct a recall on the affected lots, if necessary. -

monitoring weather conditions;

Another strategy that can be used in conjunction with a testing program is to monitor weather conditions in the areas your ingredients are harvested. If the weather conditions in that area are favorable for aflatoxin production, increase the frequency you are testing these ingredients that come into your facility. -

keeping up with aflatoxin reports;

Aflatoxin and other mycotoxin reports can also be useful in monitoring incoming ingredients. If there are reports of high levels of aflatoxins and other mycotoxins in the area your ingredients are harvested, increase the frequency of testing for these ingredients. A good report comes out each week from Neogen. -

having a lot coding program in place to be able to track ingredients as they are made into different products.

Many recalls are expanded because facilities are not able to provide documentation of their last safe batch of feed that contained a hazard.

Most importantly, make sure your suppliers are aware of the acceptable aflatoxin levels you allow into your facility and don’t be afraid to reject a load of ingredients if they surpass these levels.

If you accept a load, but it does not meet the quality standards after being tested, there are ways to mitigate the ingredient without causing harm to animals consuming the product:

-

If an ingredient is brought into your facility, but tests too high in aflatoxin, you can move that ingredient to its own bin to be fed to animals that can tolerate higher levels of aflatoxins.

Be sure to keep documentation of the segregation and production records that show which products contain the lot of this ingredient, and follow sequencing and flushing procedures to make sure there is little to no cross contamination between batches.

Don’t blend the ingredient with another load that has been tested at a lower level of aflatoxin contamination. This is unlawful, according to the FDA.

How Can Consumers Ensure Animal Food Is Safe?

There are strict food safety regulations in place for livestock, poultry and pet food producers.

Animal food producers sometimes have to recall food for safety or quality reasons (just as in the human food and produce industries).

There are many ways for you, as a consumer, to stay informed about these recalls and make sure your animal food is safe.

-

Always wash your hands before and after handling animal food. Wash bowls and utensils after use as well.

-

Save important product information regarding your livestock, poultry or pet food.

-

One easy way to keep track of this information is to keep the food in its original packaging, taking care to make sure the packaging is sealed between uses to prevent contamination.

-

If you store animal food in a separate container, place the entire bag into the container, or cut out the product Universal Product Code (UPC) and lot code identification information and secure it to the container. Update the UPC and lot code information each time you put a new bag of food into the container.

-

Be sure to use the entire product and clean out the bin between different packages.

-

When there is a product recall, you want to be able to quickly make sure the lots of product you have on hand are not part of the recall. If they are, follow the instructions in the recall announcements for product disposition. This could require you to return the product, or follow specific disposal instructions.

-

Visit FDA for more information on Proper Storage of Pet Food & Treats.

-

-

Examine products when you open the packaging for any noticeable contamination, odors or other signs of issues. In product manufacturing, the first line of defense against poor quality or contaminated ingredients is inspection at receiving. The same is true in the household or barn. As you open the packaging, take time to make sure the product looks and smells consistent with previous packages. If you notice anything off about the product, notify the company you purchased it from for options.

-

If your pet is having health issues that you suspect are food related, you can report pet food complaints to the FDA (How to Report a Pet Food Complaint). Pet Food Safety Reporting Frequently Asked Questions provides helpful information about the reporting process.

If your horse or other livestock is having health issues that you suspect are food related, you can report horse or other livestock feed/food complaints to the FDA (Reporting Problems with Horse or other Livestock Feed/Food).

Resources

Below is a list of some of the resources used to create this factsheet. These resources are great for facilities as they work on improving their food safety programs, and consumers who want to learn more about what the animal food industry is doing to make safe food and how they can continue to keep food safe at home.

-

NC State Extension Animal Food Safety and Food Safety Modernization Act

-

FDA Compliance Policy Guide Sec. 638.100 Action Levels for Aflatoxins in Animal Food

-

Hazard Analysis and Risk-Based Preventive Controls for Food for Animals

If you have questions about animal food safety, contact Marissa Cohen.

Publication date: Jan. 27, 2021

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.