An overview of the basic procedures and equipment required to manufacture heating pellets from biomass

Increased prices for nonrenewable heating fuels (such as propane, heating oil, and natural gas) have residential and farm consumers seeking more sustainable solutions to their heating needs. Price increases among these fuels will remain a trend as a combination of decreased reserves and increased demand continues to limit supply (EIA, 2012). Pellets produced from abundant biomass sources—such as grasses, crop residues, and woody fiber—are gaining acceptance as a valuable heating resource. Recently, the development of farm-scale pelleting systems has provided farmers and other consumers with greater opportunity to manufacture pellets at considerably lower costs than commercial systems. In this publication, we explain the pelleting process and considerations for consumers interested in either developing small-scale heating pellet production systems or burning pellets to meet their heating needs.

What Are Fuel Pellets?

Pellets consist of compressed biomass that is formed when plant material is forced through a die where it undergoes high temperature and pressure. The intended product consists of cylindrical pellets 3/16-inch to ¾-inch in diameter and cut to varying lengths. The length of the pellet is determined by adjusting a knife that cuts the pellets as they are pushed through the die. Most pellets are less than 1.5 inches long. During the pelleting process, biomass that has been reduced to a powder is heated in the pellet mill’s die until lignin begins to melt and flow. Lignin acts as a glue and binds plant fibers together. The result is a tightly compressed cylinder of biomass. Pellets have been produced for decades in the animal feed industry, and energy pellets are very similar but with a major difference: Energy pellet production is not concerned with palatability or animal nutrition. Therefore, energy pellets may cost less to produce. Energy pellets can be made from a wide assortment of local plant materials, such as corn stover, cotton stalks, peanut hulls, perennial grasses, poultry litter, sorghum, sunflowers, and tobacco stalks.

Advantages of Pellets

The primary advantage of pelleting is that light, fluffy biomass is densified, which dramatically reduces the space required to store the material. Pelleting also improves material handling operations and increases transportation efficiency. Pelleting research by the authors and at other institutions has indicated pellets produced from grasses can be four to nine times as dense as the chopped dry material (Mani et al., 2005; Fasina, 2008). Generally, loose biomass ranges in bulk densities between 2.5 lb/ft3 for loose straw to 15.6 lb/ft3 for wood residues (Demirbas, 2001; Tripathi, 1998). Pellet densities can surpass 50 lb/ft3 for agricultural materials and 35 lb/ft3 for woody materials (Mani, 2006; Obernberger et al., 2004). This significant increase in density reduces the amount of space required to store or ship biomass. During the pelleting process, biomass particles of different sizes are merged together, which eliminates fines that settle to the bottom of the storage or transportation container, simplifies handling, and improves burn characteristics. Finally, pelleting allows a producer to adjust the combustion characteristics of biomass by adjusting moisture content or incorporating quality enhancing additives (discussed later). These improvements provide more consistent, steady feeding of material into a firebox compared to raw biomass.

Pelleting does present some disadvantages. First, while the consistency of the fuel improves after pelleting, very little change occurs in its energy content. For example, if moisture content is the same, a pound of switchgrass pellets will have nearly the same heat energy content as a pound of dried chopped switchgrass. Pelleting modifies only the density—the pelleted switchgrass will take up much less space than the chopped switchgrass. This brings up the other major disadvantage of pelleting, which involves recovering the costs of purchasing and operating the pellet mill. Pelleting is needed only if a boiler or heater requires pellets as a fuel, if the biomass material will be packaged and transported long distances (such as exporting wood pellets from North Carolina to Europe), or if there is a need to mix different biomass materials and additives to produce a single homogenous product (such as animal feed). It is difficult to justify the time and labor costs to make pellets if they will be used on-farm in heating systems that do not explicitly require pellets as the fuel source.

The Pelleting Process

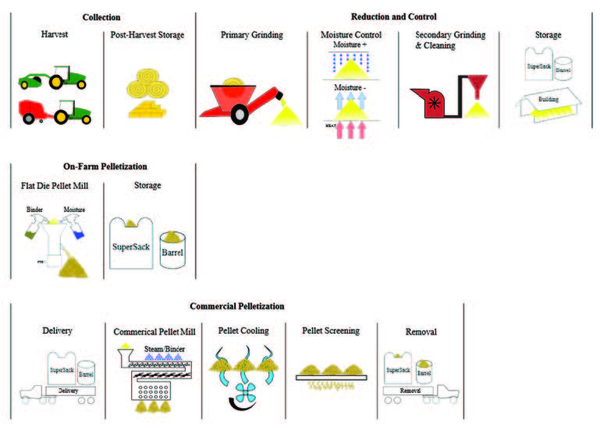

Using biomass to make pellets can be relatively simple; however, a pellet mill alone cannot complete the entire task. To make high-quality, consistent pellets, a producer must complete several preliminary tasks. Among the most important parameters to control during the pelleting process are the size and moisture content of the biomass entering the pellet mill. The optimal size and moisture content values will vary based on the mill type and its manufacturer, the biomass type, and the equipment used to grind the biomass to a smaller size. Size and moisture content must be adjusted prior to pelleting the biomass. Biomass conditioning is an optional step that may be taken to improve the “pellet-ability” of the biomass and usually involves the addition of binders or other additives that improve pellet characteristics. After the pellet is produced, it is important to provide adequate cooling for pellets as they exit the die to lessen fire hazards and improve pellet quality. An overall schematic for both farm- and industrial-scale pelleting is shown in Figure 2.

Material Reduction

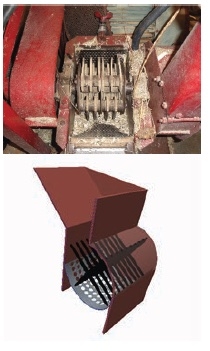

The first step after biomass collection is reducing the material to a size that can be efficiently pelletized. Pellet mills are not designed to break material down as their primary function. Typically, hammer mills or biomass grinders must be used to reduce the size of a material. Hammer mills are among the most popular machines used to complete this task. They work by swinging a gang of hammer bars around a rotating shaft to shatter the plant material until it passes through a screen (Figure 3). The size of the openings in the screen will determine how much biomass reduction occurs while hammering. Feed mixers embody a common tractor-driven hammer mill used on many farms across North Carolina (Figure 4).

Moisture Control

Controlling the moisture contained in the unprocessed plant material is critical for the production of quality pellets. A feed mixer provides a good tool to add and mix water into the biomass being fed into a pellet mill. Be sure to mix the water into the material so that it fully penetrates the material and does not simply wet the surface. Also, water should be used sparingly, as a gallon of water added to 100 lb of 10% moisture biomass will increase the moisture content by over 6%. If the biomass is too wet, a drying method is needed, which could include a mechanical dryer or sunlight. A more economical and rapid solution to dry out the biomass is using a feed mixer to incorporate very dry biomass into the mixture before pelleting. Well-dried wheat straw is well-suited for this activity.

Conditioning

Conditioning is a more difficult step to achieve with small-scale systems. Steam is a major conditioner in commercial pellet production as it provides a source of moisture correction as well as an opportunity to heat the

biomass prior to pelleting to improve pellet quality. The other objective of conditioning is to improve the binding characteristics of pellets with the introduction of binding agents. The most common binding agent used in animal feed pellet production is molasses. It is, however, relatively expensive for fuel pellet production. Alternative binders are discussed below. When using binders, there are two key points to remember: Good and thorough mixing is essential for quality pellet making and, in general, a little bit of binder goes a long way. Most binders can be added only until they are equivalent to 5% of the total biomass weight. Too much binder will hinder the pelleting process. Because a very small amount of binding agent is used, it must be added slowly and mixed in well. Adding binders too quickly will result in clumping and poor pellet making.

Typical Binding Agents

Most fuel pellets are held together by lignin that melts during the pelleting process to bind plant fibers together. Binding agents can be used either to supplement or to substitute for the biomass lignin if the biomass contains little lignin or if the plant’s structure limits access to the lignin. Binding agents also help reduce the fraction of fines, improve water resistance, increase pellet stability, and provide lubrication for the die. Besides molasses, common binders include vegetable oils, natural waxes, glycerin, and starches. In North Carolina, we have used cull sweetpotatoes as a binder. They should be used in moderation, however, as the temperature is high enough to gelatinize the potato’s starch and clog the die. An excellent binding agent is lignin sulfonate, which is a co-product of the pulp and paper industry. Lignin sulfonate is available from several suppliers in both a liquid and powder form. A major drawback to lignin sulfonate is that it is usually sold in bulk, which exceeds the needs of a small pelleting operation.

Pelleting Systems

There are two types of pellet mills used to produce energy pellets. Small-scale mills (those that produce less than 1 ton/hr) are usually the flat die mill type (Figure 6). In flat die mills, material falls down on top of the pellet die and a set of rollers presses the material into the holes on the die to form the pellets. Flat die mills rely on these rollers to compress and distribute the material to be pelleted across the die. A flat die mill has a rotating knife under the die that cuts the pellets to a pre-set length. These systems provide limited opportunity to adjust pellet material characteristics. Although this lack of sophistication makes these systems cheaper, they can be difficult to operate when the material being pelleted is not at ideal conditions.

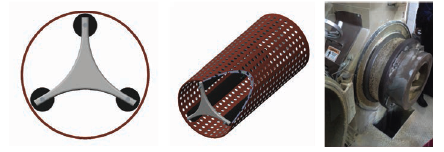

Commercial-scale pellet mills are usually known as ring die machines (Figure 7) and are very different from the flat die pellet mill described above. In most ring die units, the die is powered and rotates. The compression wheels simply turn as a result of frictional forces from contact with the spinning die. Properly conditioned material is augured into the die chamber along a horizontal axis (as opposed to dropping in vertically in a flat die mill). The material is spread along the face of the die by the rotating compression wheels. Some ring die mills are equipped with feed distributor flights that further help spread the material across the die face. Knives set at specified gap distances outside of the ring then cut the extruded pellets once a certain length is achieved.

Pellet Management

After the pellets are ejected from the pellet mill, cooling and removal of fines are necessary to ensure pellet quality. As the pellet cools, it hardens and its durability improves. Cooling also will prevent fire hazards when storing hot pellets. The fines are small biomass particles that did not form into a pellet. Their presence will cause uneven combustion of the fuel and can speed degradation of the pelleted biomass. Using a screen or shaking conveyer as the pellets exit the mill can remove the fines. The collected fines can then be reintroduced into the pellet mill. Expanded metal on a suitable support can be utilized as an economical means to develop a screen.

Pelleting Safety

Health hazards are present during the pelleting process, so caution should be used when making pellets. Making pellets involves the use of powered equipment that has inherent hazards. Be sure to discuss the equipment’s operation with the manufacturer, read all operator manuals prior to operation, and maintain all safety guards. Dust and equipment noise also present hazards, so personal protective equipment (PPE) such as respirators, safety glasses, and ear plugs should be employed. Finally, a fire hazard arises when hot pellets pile up immediately after they are formed in the mill. If the pellets are not cooled properly, they are liable to combust. Another fire hazard can result if wet biomass is stored before pelleting. This wet material will heat up as a result of microbial activity and could also spontaneously combust.

Pellet Storage

After pellets are extruded from the pellet mill and allowed to cool, they must remain in dry storage. At this writing in 2013, manufacturing water-repellent pellets on a small-scale is difficult because of equipment and additive limitations. When pellets produced by small pelleting systems get wet, they will tend to absorb water, become puffy and soft, and ultimately crumble into dust. There are a number of options available to keep pellets dry and stable after they are manufactured. Commodity sheds, grain bins, and large bags (super sacks) can be used. Keep in mind that the storage surface must remain as dry as possible to keep the pellets stable. After manufacture, pellets should stay at a stable 10% moisture content. Pellets can be augured, conveyed, or elevated using conventional grain handling equipment. Under high humidity conditions, pellets may develop mold or fungal growth. Proper air circulation and material turnover can reduce the potential for this microbial activity.

Pellet Mill Considerations

A number of considerations should be addressed prior to buying a pellet mill. The material used for pelleting, capital and operating costs, system input/output values, and complexity of the operation are among the most important items to consider. Cost will be one of the biggest factors, and it should be noted that production can cost between $75,000 to $250,000 per ton-per hour of capacity for commercial pellet mills (Ciolkosz, 2009). The costs vary based on the infrastructure used to house and operate the pellet mill, as well as the specifications of the mill itself. Commercial-scale pellet mills are beyond the scope of this fact sheet, so our discussion will focus on farm-scale pellet mills that require significantly less infrastructure, utilities, and knowledge to operate.

There are several companies that sell small pelleting systems that are capable of making pellets from a variety of ground-up biomass materials and require relatively low capital to purchase (less than $5,000). Nearly all of these units are flat die pellet mills and are limited to less than a ton of pellets an hour under ideal conditions (Figure 8). Many of these systems are imported, but a few manufacturers in the United States are offering mills driven by electric motors or tractor PTO shafts. If you are considering a farm-scale mill, ask the pellet mill supplier or manufacturer some key questions:

- Has the pelleting feedstock of interest been processed in this particular pellet mill?

- What is the production rate of the pellet mill for the feedstock of interest, and what are the required material properties (grind size, moisture content, binders) required to achieve that production rate?

- Can samples of pellets generated by the mill be provided for feedstocks of interest? If they are not available, ask about submitting sample feedstock for evaluation. Make sure the biomass of interest has been processed in the mill before you decide to purchase one.

- Is a demonstration or try-out allowed with the mill being considered for purchase? Knowing how the mill will perform with the biomass material of interest is a reasonable request.

- How much power is needed to operate the mill, and what are the options for powering the mill?

- What are the wear parts on the mill, what is the life of these parts, and what are their costs?

Farm-Scale Pellet Mill Moisture Control

As mentioned before, the moisture in the material being pelleted will affect both the efficiency of the pelleting machine as well as the potential for quality degradation. Having material too wet or too dry will lead to poor quality pellets or prevent the pellet mill from manufacturing any pellets. Unlike commercial pelleting systems that have access to high throughput dryers and steam conditioning systems, farm-scale systems require careful monitoring of biomass moisture content. A windrow hay moisture meter is a good, versatile tool for monitoring the moisture content of a variety of biomass resources and mixtures. Here we will describe our experience with moisture content in making pellets with a farm-scale pellet machine. When the material is too wet, in the range of 16% to 18% (wet basis) or higher, the excess water acts as a coolant. The pellet mill cannot generate enough heat to convert the water into steam and make good pellets. Very soft, long, curly pellets are a clear indicator the material is too wet. Having material that is too dry, typically less than 10% moisture, also negatively affects steam production. Dry material does not have enough free water to make steam, and the material will not properly bind. A clear indicator of dry material is very fine dust passing through the die without pelleting. Also, a solid mat of material between the rollers and die of the pellet mill will fail to form, and the formation of this mat is critical for pellet making. If the material is too dry, the rollers just keep kicking up and swirling the powderized biomass and will not push it into the die.

Pellet Quality Control

The Pellet Fuels Institute has provided a set of standards to guarantee the quality of densified biomass fuels. Their standard can be found online. This standard sets three grades of pellets: premium, standard, and utility (in order of declining quality). The main characteristics that differentiate the pellet grades are density, presence of fines, ash content, and moisture. The premium pellets have the fewest fines and the least ash and moisture, and they represent the highest density material. Pellet density is, to some extent, a function of the quality of materials going into the mill. But for the most part, the design and performance of the mill will be the limiting factors in how dense the final pellet will be. The other quality properties can be adjusted through pre- and post-processing operations. Fines can be adjusted through post-pellet screening, moisture can be adjusted by pre-pellet drying or moisture addition, and ash content will be inherent to the material used to make the pellets.

Economics Of Pellet Making And Use

The cost to make pellets is a significant factor when it comes to both marketing pellets (setting a sales price) and consuming pellets (determining if it is financially better to burn pellets instead of natural gas or wood chips). Several studies have been conducted that studied the economics of pellet-making from biomass at an industrial scale, but very few studies have focused on farm-scale production. In general terms, the price for producing pellets breaks down into three areas: feedstock (up to 40% of total cost), drying (up to 30% of total cost), and labor (up to 25% of total cost) (Mani, 2006; Garstang, 2001). The actual pelleting equipment costs are less than 12% of the total production cost (Nolan et al., 2010).

Most studies indicate that pelleting costs are primarily tied to the feedstock used to make the pellets. In other words, the price paid to acquire biomass is difficult to offset in the manufacturing process. All things being equal on the pellet mill side of processing, buying biomass for $60/dry ton will always lead to more expensive pellets than purchasing biomass at $25/dry ton. Estimates place the cost of acquiring biomass at 40% of the final cost to produce a pellet. Fasina (2006) estimated the cost of making pellets from different materials as follows: $8.60/ton for switchgrass, $37.88/ton for peanut hulls, and $5.66/ton for poultry litter. These costs reflect only the pelleting cost, not the cost of the feedstock and any additives, drying, grinding, and storage. Nolan et al. (2010) estimated the cost for final pelleted products starting with nonwoody biomass raw material to be approximately $135/ton, which includes all potential costs. Both of these studies were conducted for high-throughput ring die mills and are not accurate for farm-scale flat die mills. But at the time both studies were completed, the cost of the pellets as a heating fuel was cheaper than most sources of nonrenewable heating fuels (such as natural gas, propane, and heating oil).

Pellet Heating and Heating Values

Pellets present unique combustion characteristics and should be used only in boilers, heaters, and stoves that have been designed to use pellets as a fuel source. Additionally, wood pellet stoves should not be used to burn nonwoody biomass pellets unless the manufacturer specifically says a stove is designed to handle such material. There are several pellet boilers, heaters, and stoves on the market. Select a pellet mill based on your consideration of these critical factors: pellet type, pellet size, heating requirements, and infrastructural requirements.

Heating values for pellets are a direct result of the materials used to make the pellets. Pelleting does not improve the amount of energy in the biomass. It simply places the biomass in a more compact, dense form. A pound of switchgrass pellets contains essentially the same amount of energy as a pound of recently harvested dried switchgrass. The key reason for pelleting is to improve the packaging of the biomass fuel. Pellets require less storage space and are easier to convey than many ”raw” forms of biomass. Pellets also provide a more efficient means of transport as they can be bagged, augured, and bin stored. So although pellets will not improve the heating characteristics, they provide better storage and transport opportunities for a pellet maker. In some cases, heating values of a biomass pellet may be slightly greater than the raw biomass form. If that is the case, then the binding additives used to help form the pellet have added additional heat energy potential. For more information on heating values, please refer to a related N.C. Cooperative Extension publication: A Guide to Biomass Fuels in North Carolina (AG-783).

Pelleting Problems and Concerns

Because pelleting requires several operations, numerous unforeseen obstacles can occur. Some of the obstacles encountered during our research are described here to provide the reader with some additional considerations if on-farm pelleting is being considered. First, material drying has proven to be a laborious task in farm-scale forced-air driers. These dryers can take over an hour to load and unload but yield small amounts of usable material for time invested. Rodent and insect impact on material has also been observed. While a producer is storing the raw material on-farm prior to making pellets, insects such as fire ants can infest the material and rodents can remove material to build nests—with a material loss resulting in both cases. Pellet generation in small-scale flat die pellet mills can be a challenge as conditions (moisture, material size, material consistency, die temperature) need to be ideal for adequate production. These small pellet mills do not have the auxiliary systems to improve conditions easily. Over time, the flat die on a pellet mill will wear unevenly, which will require the die to be resurfaced or replaced. Both options are expensive. As wear occurs, the time to effective extrusion increases to the point that pellets are not generated. Many flat die pellet mills, especially those imported, are constructed using cast parts that can fail prematurely.

If a larger commercial pellet mill is used to generate pellets, there are additional concerns. Commercial-scale pellet mills are highly sensitive to fines or variations in material size. Therefore, it is essential that grinding and hammer mill operations are carried out using the proper milling equipment. To ensure uniformity, multiple grindings through different size screens may be necessary. For example, material may initially be hammer milled using a ¾-inch screen, followed by a 3/8-inch screen, and lastly, a 3/16-inch screen to achieve a consistent feed material for the pellet mill. Attempting to go straight to a 3/16-inch screen will dramatically cut the hammer mill’s efficiency and create a ground material that is not very uniform (on a single pass).

Conclusions

While pelleting provides an opportunity for a farm or residential consumer to create their own heating fuel, it is important to fully understand the process before committing resources to pellet making. Is pelleting absolutely necessary? Determining that is the first step in figuring out if a system is appropriate for a particular application. Communication with the manufacturers of the pelleting equipment and heating system will be necessary to purchase the correct equipment for your pelleting and heating needs. For instance, some pellet mills work well with ground wood or sawdust as a feedstock, whereas others will perform better with grasses. Additionally, the condition of the biomass entering the mill (including moisture content, particle size, and particle distribution) will be determined by the manufacturer of the pellet mill. Because of the variability in mill types and capacities, it will be important to have these conversations with manufacturers early in your considerations to ensure a proper system is constructed to meet your needs.

References and Resources

Ciolkosz, D. 2009. Manufacturing Fuel Pellets from Biomass. University Park, PA: Penn State Agricultural Research and Cooperative Extension.

Demirbas, A. 2001. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Conservation and Management 42:1357-78.

Energy Information Administration (EIA). 2013. Annual Energy Outlook. Washington, DC: US Department of Energy.

Fasina, O.O., D. Bransby, J. Sibley, and C. Gilliam. 2006. Heating of greenhouse with biofuel pellets (ASABE Paper No. 064183). 2006 ASABE International Meeting (Portland, OR). St. Joseph, MI: American Society of Agricultural and Biological Engineers.

Fasina, O.O. 2008. Physical properties of peanut hull pellets. Bioresource Technology 99(5): 1259-1266.

Garstang, J. 2001 September. Transportation Issues. Presentation at National Energy Crops Conference. (London, England). London: Department for Environment, Food, & Rural Affairs (DEFRA).

Lehtikangas, P. 2001. Quality properties of pelletised sawdust, logging residues, and bark. Biomass and Bioenergy 20(5):351-360.

Mani, S., S. Sokhansanj, X. Bi, and A. Turhollow. 2006. Economics of producing pellets from biomass. Applied Engineering in Agriculture 22(3):421-426.

Mani, S., L. Tabil, and S. Sokhansanj. 2006. Effects of compressive force, particle size, and moisture content on mechanical properties of biomass pellets from grasses. Biomass and Bioenergy 30(7):648-654.

Nolan, A., K. McDonnell, G.J. Delvin, J.P. Carroll, and J. Finnan. 2010. Economic analysis of manufacturing costs of pellet production in the Republic of Ireland using nonwoody biomass. The Open Renewable Energy Journal 2010(3):1-11.

Obernberger, I., and G. Thek. 2004. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass and Bioenergy 27(6):653-669.

Pellet Fuels Institute (PFI). 2008. PFI Standard Specification for Residential/Commercial Densified Fuel. Arlington, VA: PFI.

Pfost, H.B. 1964. The effect of lignin binders, die thickness, and temperature on pelleting process. Feedstuffs 36(22):20, 54.

Samson, R., S. Bailey-Stamler, and C. Ho. 2006. Optimization of Switchgrass Management for Commercial Fuel Pellet Production. Alternative Renewable Fuels Research and Development Fund project summaries. Ste-Anne-de-Bellevue, QC: Resource Efficient Agricultural Production—Canada (REAP).

Tripathi, A.K., P.R.V. Iyer, and T.C. Kandpal. 1998. A techno-economic evaluation of biomass briquetting in India. Biomass and Bioenergy 14:479-488.

Prepared by

Matthew W. Veal, Assistant Professor and Extension Specialist

Edward E. Godfrey III, Research AssociateDepartment of Biological and Agricultural Engineering

NC State University

Photographs by M. W. Veal and E. E. Godfrey III

Publication date: Sept. 4, 2014

Reviewed/Revised: May 22, 2024

AG-785

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.