To sell, label, or represent their products as “organic,” growers and processors who sell organic products valued at $5,000 or more a year must be certified by a certifying agent accredited by the U.S. Department of Agriculture (USDA). The National Organic Program Final Rule (NOPFR) spells out requirements for organic crop and livestock production, handling, certification, and recordkeeping. The NOPFR and other related documents are available aon the USDA website.

Organic Certification Process

Because all certifiers must follow USDA requirements, the organic certification process is similar across certifiers. The farmer-applicant, the certifying agent, and the inspector must complete specific steps.

The Farmer

A farmer seeking certification must do the following:

- Comply with the federal standards for organic production (see “Federal Standards for Organic Certification”).

- Choose a certifier.

- Complete an Organic System Plan (or Organic Farm Plan), which is also considered the application for certification. The Organic System Plan describes the producer’s operation and demonstrates how practices and inputs align with the standards of the National Organic Program. The Organic System Plan must describe all relevant aspects of the operation, including farm maps, and document a three-year field history for crops planted and inputs applied. (See “Recordkeeping: A Critical Requirement” later in this chapter for more details.)

- Submit the completed Organic System Plan with application fees and other required documents to the certification agency.

The Certifying Agent

- Reviews the Organic System Plan and accompanying documentation to ensure completeness and determine whether the applicant appears to comply or has the ability to comply.

- Verifies information regarding any previous certifications, notification of noncompliance, or denials of certification.

- Arranges an on-site inspection of the farm, the next step toward certification. The certifying agent assigns an organic inspector, who schedules an inspection appointment with the applicant. The inspection may take between three and six hours, depending on the complexity of the operation.

The Inspector

- Verifies information from the Organic System Plan. To accomplish this, he or she inspects fields, farm buildings, and equipment; assesses contamination risks; fills out an on-site inspection report; and gathers as much information as needed for the certifying agent to determine if the operation complies with federal standards.

- Evaluates crop health and growth, soil tilth, the fertility management program, pest and weed management strategies, seed sources, adjoining land uses, and the applicant’s understanding of and commitment to compliance.

- Reviews records to ensure monitoring and compliance. The inspector may be authorized to take soil, tissue, or product samples for analysis. The inspector reviews any noncompliance issues at the time of the inspection.

- Conducts an exit interview with the applicant to confirm the accuracy and completeness of the observations and information gathered, to address the need for additional information, and to discuss issues of concern.

- Completes a report based on the information gathered. The inspector does not make the certification decision, but identifies noncompliance issues with regard to organic standards or inconsistencies between what is documented during the inspection and what is reported in the Organic System Plan.

- Sends the inspection report and all associated paperwork to the certifying agent.

What Happens Next?

After the inspection, the certifying agent assigns a certification committee, staff members, or review committee to review the Organic System Plan, the inspection report, and all associated documentation. If the certifying agent determines compliance in all procedures and activities, the applicant is granted certification and is issued a certificate of organic operation that must be renewed each year. If the certifying agent determines any minor noncompliance issues, the applicant has the opportunity to correct these noncompliances as a condition of certification.

Maintaining Organic Certification

To maintain organic certification each year, the certified farmer must pay annual certification fees, submit an updated Organic System Plan detailing changes from the previous year, and submit an update on corrections of any minor noncompliance issues previously identified by the certifying agent. Other records or information may be needed if deemed necessary. Each farm must be inspected at least once annually to maintain certification. The updated Organic System Plan and inspection report must also be completely reviewed by the certifying agent before the farm receives a renewed certificate for the organic operation. (See “Federal Standards for Organic Certification.”)

Denial of Certification

If certification is to be denied, the certifying agent must provide the applicant with written notification of noncompliance, giving the date by which the correction must be accomplished, and specifying any documentation necessary to support correction. The applicant may rebut in writing any noncompliances identified by the certifying agent. When a correction is not possible, a notification of noncompliance and notification of denial of certification is provided to the applicant. This notification is also provided to the USDA National Organic Program administrator.

Reapplying

The applicant can reapply for certification when any noncompliances are corrected, or request mediation with the certifying agent. When applying to a different certification agency, the applicant must submit a copy of the previous denial of certification with the application paperwork to the new certifier.

Filing an Appeal

An applicant can file an appeal of the denial of certification with the USDA National Organic Program administrator. If the certifying agent has reason to believe that the applicant made false statements or otherwise misrepresented compliance, the agent can simultaneously deny certification and issue a notification of noncompliance.

Federal Standards for Organic Certification

To become a certified organic production operation, the farm and farm practices must comply with the Organic Foods Production Act of 1990 and the USDA National Organic Program rules and regulations (Federal Register, Vol. 65, No. 246, pgs. 80367-80663).

In simplified terms, National Organic Standards for crop farms require the following:

- Proof that no prohibited materials have been applied to the crop for three years (36 months) prior to harvest. (A list of prohibited materials is provided below.)

- Distinct, defined boundaries for the organic operation.

- Implementation of an Organic System Plan, with proactive fertility systems, conservation measures, and environmentally sound manure, weed, disease, and pest management practices.

- Monitoring of the operation’s management practices.

- Use of natural inputs or approved synthetic substances on the National List, provided that proactive management practices are implemented prior to use of approved inputs.

- Management of compost production and use. If compost is used for fertility, it may be applied at any time but must be managed according to very specific parameters under the National Organic Standard requirements for compost production.

- Management of raw animal manure. If raw animal manure is used for fertility, it must be managed according to the crop being produced:

Feed crops (crops not intended for human consumption) may be incorporated at any time into the soil before harvest.

Crops for human consumption must be incorporated at least 90 days prior to harvesting a crop where the edible portion of the plant does not have contact with soil or soil particles, or 120 days prior to harvest of crops where edible portions do have contact with soil or could be splashed with soil particles. - Use of organic seeds, when commercially available (and no use of seeds treated with prohibited synthetic materials, such as fungicides, as noted below).

- Use of organic seedlings for annual crops when commercially available.

National Organic Standards prohibit the following:

- Use of genetically engineered organisms (GMOs), defined in the rule as “excluded methods.”

- Residues of prohibited substances exceeding 5% of the EPA tolerance. A certifier may require residue analysis if there is reason to believe that a crop has come into contact with prohibited substances or was produced using GMOs.

- Use of sewage sludge.

- Irradiation.

- Use of any synthetic substance not on the National List.

- Use of any other prohibited substances on the National List.

- Field burning to dispose of crop residues. (Burning may be used only to suppress disease or to stimulate seed germination. Flame weeding is allowed.)

In addition, organic producers must do the following:

- Maintain or improve the physical, chemical, and biological condition of the soil; minimize soil erosion; and implement soil-building crop rotations.

- Use fertility management systems that do not contaminate crops, soil, or water with plant nutrients, pathogens, heavy metals, or prohibited substances.

- Maintain buffer zones, depending on risk of contamination.

- Prevent commingling of split operations. (The entire farm does not have to be converted to organic production, provided that sufficient measures are in place to segregate organic from nonorganic crops and production inputs).

- Maintain records for at least five years.

Recordkeeping: A Critical Requirement

Recordkeeping is critical to organic certification. A certified operation must maintain records that document the production, harvest, and handling of agricultural products intended to be sold, labeled, or represented as organic. Records must be adapted to the particular commodity that the certified operation is producing. For example, an organic grain farmer must keep records pertaining to the processes and facilities involved in the production, handling, and marketing of the organic grain crops, such as storage, cleanout, and transportation records. Records must also fully disclose all activities and transactions of the certified operation in sufficient detail as to be readily understood and audited.

All records must be maintained for at least five years beyond their creation, and sufficiently demonstrate compliance with the National Organic Program rules and regulations. Split operations (organic and conventional production on the same farm) must also maintain records on the conventional processes and facilities to ensure that no commingling occurs. The certified operation must make all relevant records available for inspection and copying during normal business hours by authorized representatives of the Secretary of Agriculture, the applicable state program’s governing official, and the certifying agent.

One of the primary recordkeeping requirements of organic certification is maintaining an audit trail—the records that show the commodity was produced using only approved inputs, processes, and facilities. This can be challenging; many new applicants are unsure of what documents are needed, and they do not know what an inspector needs to review during inspection. The documents needed by the inspector depend on the production operation, but some basic documents are required for nearly every farm:

Farm Maps

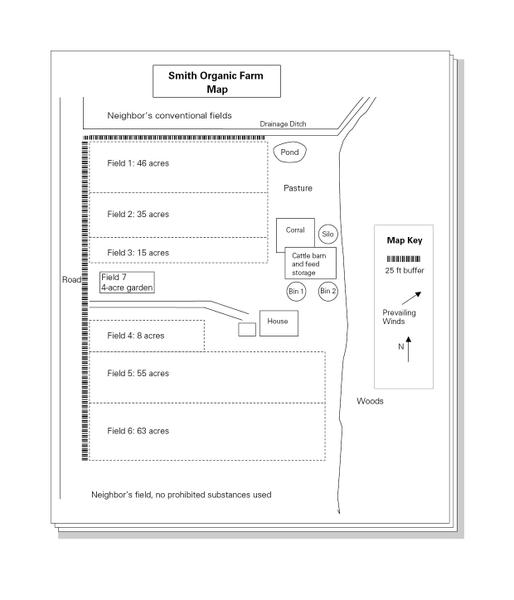

A farm map must clearly show the layout of the farm and the land use in areas surrounding the farm or the organic fields (Figure 12-1). Maps must depict the following:

- Outlines of the fields. Indicate the field number and acreage of each field.

- Adjoining land uses. Indicate if adjoining land is cropped or not, and if cropped, if it is conventionally or organically managed. If any farmland or adjoining land is not cropped, its use must be noted (such as pasture, woods or trees, rivers, and roads).

- Location of any water crossing a field and in what direction it flows. If there are waterways established in a field, these need to be marked.

- Location of any structures on the land. Structures should be identified, whether they are bins, equipment storage areas, buildings, or homes.

- Location of fields in relationship to one another. If the farm is very large, include one map showing all fields and their relationship to each other. Supplemental maps can depict individual fields or groups of fields.

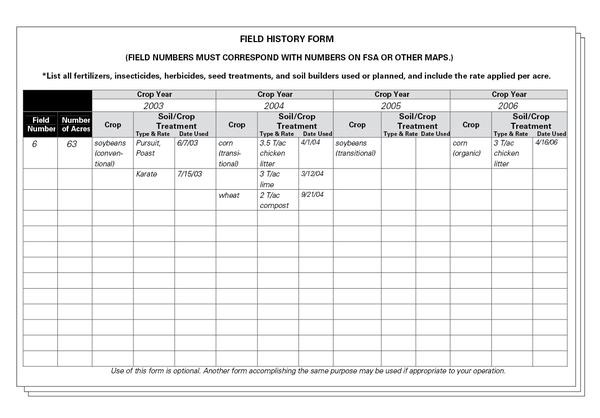

Field History

The certifying agent reviews the field history to determine if a field is eligible for certification. This document must include the field number and acreage, what is grown currently and what has been grown for the past three years, the types of inputs used (both approved and prohibited), and the dates the inputs were used (Figure 12-2). For fields transitioning to organic, the dates of inputs are critical in determining the date each field will be eligible for certification, so be as specific as possible. It is best to indicate the year, month and day of the last input used. If this is not possible, at least indicate the month and year of the last use of a prohibited material so your certifier can determine when the field is eligible for certification.

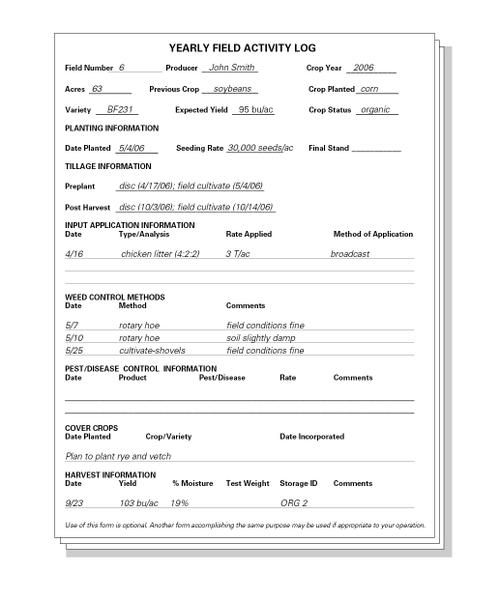

Field Activity Logs

These are probably the most important but least understood components of the audit trail. This is where the majority of the information regarding actual farming activity is kept. The field activity log, or field record, should show all field prep work, planting information, post-planting fieldwork (such as cultivation, fertilization, and pest management), dates and rates of any and all inputs, and harvest dates for each field in the organic operation (Figure 12-3). A field log can be kept in a number of ways. Carrying a pocket calendar and simply jotting down daily activities is a very simple and clear way to keep a field record. But one disadvantage of this system is that only one year’s information is recorded at a time. Another approach is to keep a notebook that is regularly updated for each field. This helps track what happens in each field over a time span of several years. If keeping track of many fields is too difficult, a three-ring binder with a yearly record sheet for each field may be easier for long-term tracking. Computer software, such as simple spreadsheets, can also be used to maintain field activity records. Select a method that ensures documentation of all the required information in a way that works well for your operation.

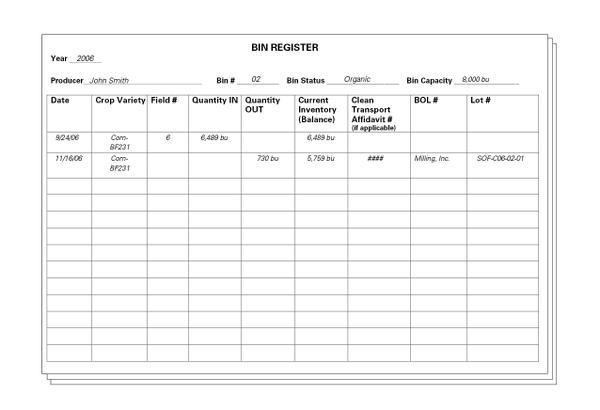

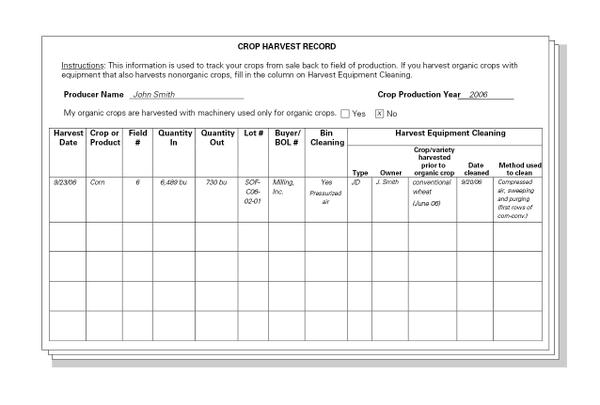

Storage Logs

These logs are needed only if crops are stored on the farm prior to sale. Grain farms will usually need some storage records (Figure 12-4). For organic certification, the following information is required: crop, amount, and date added to a bin or storage unit and what field it came from; crop, amount, and date removed from a bin; and the lot number for the sale (also see “Sales Documentation” below). If the storage bin was previously used for nonorganic crop storage, the storage log must indicate how and when the bin was cleaned prior to storing organic crops.

Sales Documentation

This refers to all the information attached to a sale of organic products. It should include scale tickets, bills of lading, clean transport documentation, and invoices for sales. Also included in sales documentation should be the word “organic” and the lot number for the product sold. A lot number is an identification number used to track any crop sold as organic back to the originating field (Figure 12-5). This number is unique to each sale, but it should be based on a formula that is easy to remember because it needs to be consistently used.

Example

If Smith Organic Farm makes an organic sale for a soybean crop stored on the farm, the farmer would use a lot number such as “SOF-SB06-01-03.” This number would signify:

| Description | Code |

|---|---|

| Smith Organic Farm | SOF- |

| soybeans harvested in 2006 and | SB06- |

| stored in bin number 01 | 01- |

| third load sold from that bin. | 03 |

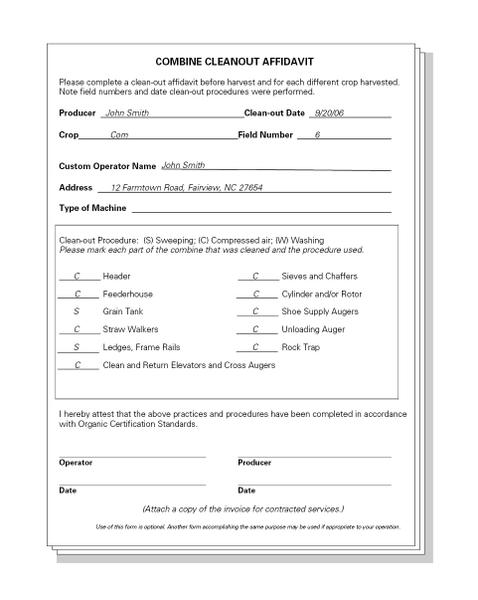

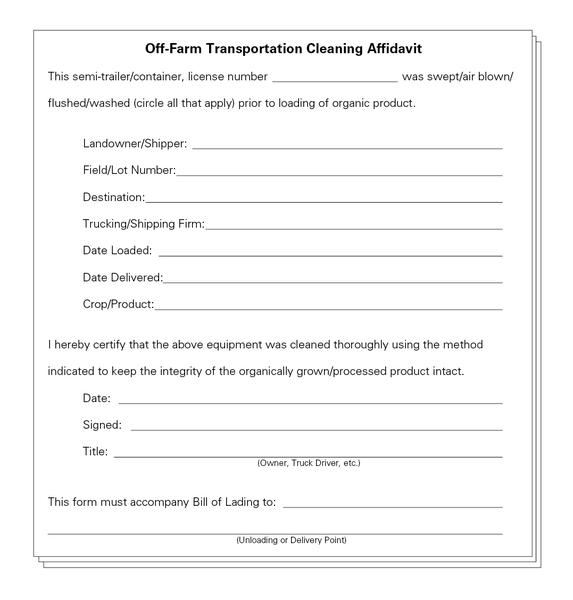

Split Production Records

Keep in mind that if an organic farm grows the same crop both organically and conventionally, the inspector will need to see all harvest, storage, and sales records for both crops. This is necessary to verify that no commingling occurs between organic and nonorganic crops. Additionally, the records must show that all equipment was cleaned between uses in organic and nonorganic fields (Figure 12-6). This kind of affidavit is required for any equipment shared between organic and nonorganic production, any rented equipment, or any field work completed by an outside contractor on a custom basis. The cleaning of transportation vehicles also must be documented. The cleanout date, previous product transported, organic product transported, cleaning activity, and name(s) of the driver(s) are generally needed for the documentation (Figure 12-7). Consult the certifier about specific cleanout procedures. Storage bins or containers and areas used for organic crops should be thoroughly cleaned before use and clearly labeled “organic.”

This guide includes several samples of the kinds of documents needed to create an organic audit trail (Figures 12-1 through 12-9). These specific documents are not required, but they can be used as templates that you can modify to match your production needs. Contact your certifier if you have specific questions regarding the requirements for audit trail documentation. Additional recordkeeping templates can be downloaded from the Carolina Farm Stewardship Association, or from the National Center for Appropriate Technology.

Certification Agencies

A list of all USDA-accredited organic-certifying agencies can be found in the Organic Integrity Database. Physical copies can be obtained by request from the National Organic Plan (NOP) office at 1400 Independence Avenue, SW, Room 2510 South Building, Washington, DC, 20250.

Choosing a Certifier

When choosing an organic certifier, an applicant should consider several factors. First, it may be helpful to choose a certifier that the end-user of your product recommends. For example, you could choose the certifier used by the organic mill who buys your organic grain.

Location and Fees

Consider the location of inspectors that the certifier uses. Most certifiers require the applicant to pay all expenses associated with the on-site inspection, including travel. Because the USDA requires that certifiers fully disclose all fees, an applicant can also compare certifiers based on expense or fees.

Turnaround time and experience

Also consider the turn-around time required by certifiers to process an application, and the experience the certifier has in certifying a particular type of operation. Some applicants choose a certifying agent based on the agency’s level of involvement in organic certification policy and advocacy at state and national levels.

Organic Compliance in Grain Production

Organic grain production involves some specific requirements that may not apply to other farms and commodities because of the way grain is produced, stored, and sold.

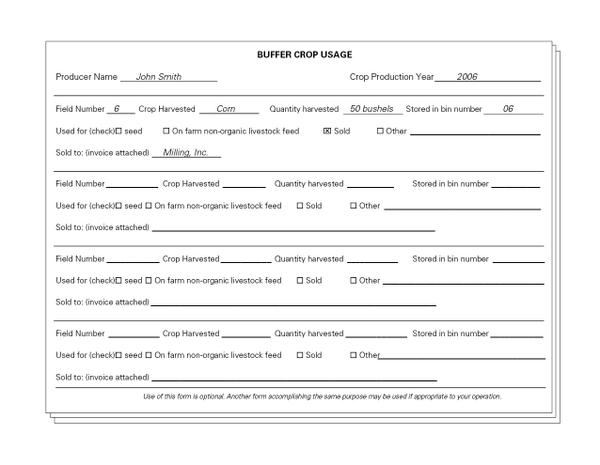

Isolation buffers

The size requirements vary for isolation buffers between organic land and adjacent nonorganic land, depending on land uses, prevailing winds, runoff directions, ditches, and other barriers. An isolation buffer is usually between 20 and 50 feet wide. However, cross-pollinated or wind-pollinated organic crops (such as corn) should be isolated from GMO crops of the same type by a larger buffer to maintain seed purity. Part of a field buffer can consist of the outside rows of a crop field, harvested and sold as conventional (Figure 12-8). Confirm buffer distances with your certification agency. If an applicant can provide a written statement from his or her neighbors that no prohibited materials are being used on adjoining land, the organic operation may not need a buffer at all.

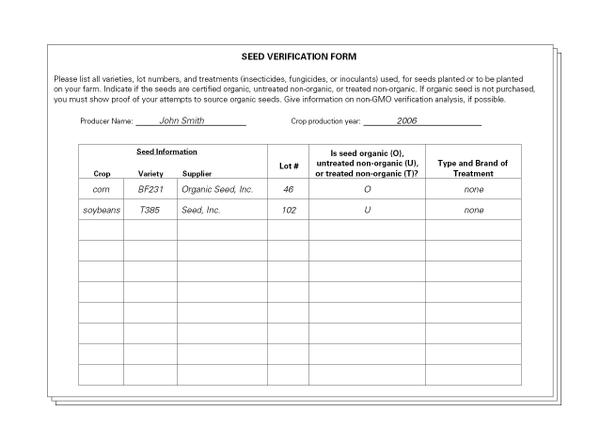

Organic seed

Organic seed must be used when commercially available. In many cases, however, the crop or variety desired is not commercially available as organic seed. This is particularly true for organic grain production. Generally, the applicant must contact at least three seed companies or sources that carry organic seeds and try to obtain organic seed of the crop or variety desired. The three seed sources contacted must produce or supply seed of the crop desired. The applicant must document the contact, including the date; whether the contact involved a telephone, fax, letter, or email message; the crop and variety; and the most comparable variety with organic seed source and price (Figure 12-9). The certifying agent may require a copy of this documentation if nonorganic seed is used.

Accidental contamination

Accidental contamination of a farm by prohibited substances can occur because of spraying by the Department of Transportation (DOT), electrical companies, or neighbors. It is important to communicate very clearly about your organic operation and display signs that indicate organic land. Inform the DOT and electrical companies about the location of organic land and specifically ask them to avoid spraying the area.

Pesticides

A number of pesticides—mainly non-synthetic compounds and biocontrols—are approved for use in certified organic production systems. Insecticides include neem, Bacillus thuringiensis, Beauvaria spp., diatomaceous earth, pyrethrum, spinosads, horticultural oils, and species of Trichoderma. Fungicides include hydrogen peroxide, potassium and sodium bicarbonate, copper products, sulfur, species of Pseudomonas, and pesticidal soaps. While these products have potential for controlling insect or disease pests, or both, no research has been conducted with them on grain crops in North Carolina, and we cannot make recommendations for their use in this state. The cost of pesticides approved for organic production may also be prohibitively expensive for field crops. Conditions for use of an approved pesticide must be documented in the organic system plan as required by the 2000 National Organic Plan before a pesticide is used.

The Organic Materials Review Institute (OMRI) publishes a list of commercially available products that can be used in certified organic operations for pest control. Some approved products may not be listed by OMRI, but always check with your certifier before using any product. Some certifiers charge a fee for reviewing any pesticide that will be used on a crop. Always contact your certifier prior to using any pesticide to document use or to gain approval for use.

Publication date: March 19, 2024

AG-660

Other Publications in North Carolina Organic Commodities Production Guide

- Chapter 1: Introduction

- Chapter 2: Organic Crop Production Systems

- Chapter 3: Crop Production Management - Corn

- Chapter 4: Crop Production Management - Wheat and Small Grains

- Chapter 5: Crop Production Management - Organic Soybeans

- Chapter 6: Crop Production Management - Flue-Cured Tobacco

- Chapter 7: Crop Production Management - Peanuts

- Chapter 8: Crop Production Management - Sweetpotatoes

- Chapter 9: Soil Management

- Chapter 10: Weed Management

- Chapter 11: Rolled Cover Crop Mulches for Organic Corn and Soybean Production

- Chapter 12: Organic Certification

- Chapter 13: Marketing Organic Grain Crops and Budgets

- Chapter 14: Organic Market Outlook and Budgets

- Chapter 15: Resources for More Information on Organic Commodity Production

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.