This publication summarizes on-farm research work conducted in North Carolina to assess the potential of sorghum as a bioenergy feedstock in sprayfields and non-sprayfields (Heitman et al. 2017a, 2017b, and 2018).

Introduction

Interest in economical alternatives to fossil fuels has grown over the past several decades, in part because of greater energy demand and the need to reduce reliance on fossil fuels. Sorghum [Sorghum bicolor (L.) Moench] is an annual grass that has emerged as a potential dedicated bioenergy feedstock (Figure 1). High biomass at harvest and nutrient removal potential are desirable characteristics for crops to be planted on land receiving large quantities of animal waste effluent, for example, from lagoons in swine sprayfields of North Carolina. Understanding differences in biomass harvested and nutrient partition among stem, leaf, and panicle components, and their interactions with management practices such as nitrogen fertilization rate, can aid in hybrid selection and development of harvest management practices to optimize the quality of the harvested feedstock and to inform nutrient management plans.

Field Trials

On-farm trials were conducted in North Carolina for four years (2012 to 2015) to evaluate nitrogen fertilization effects on biomass production, nutrient removal, and partitioning of biomass and nutrient removal. Experimental areas were located on-farm at sprayfields in Duplin, Wayne, and Sampson Counties and at the Williamsdale Biofuel Field Lab near Wallace, NC.

Sweet sorghum cultivar M81-E and biomass sorghum Blade ES5200 were planted in 30-inch rows (plot size was 141 × 90 feet) between late April and early June. In non-sprayfield areas, plots were fertilized with nitrogen rates of 0, 60, 120, 180, and 240 pounds per acre. At the sprayfields, nutrient (nitrogen, phosphorus, and potassium) loadings were monitored using in-field precipitation gauges. Across four years and three locations, loading for total nitrogen ranged from 36 to 556 pounds of nitrogen per acre, 6 to 99 pounds of phosphorus per acre, and 59 to 1,040 pounds of potassium per acre.

Plots were harvested between September and October each year using a Wintersteiger forage harvester (Figure 2). Sorghum was at midreproductive growth stage at time of harvest. Average length of the growing season, from planting date to harvest, was 140 days (±16).

Biomass Harvested, Plant Height, and Nutrient Removal

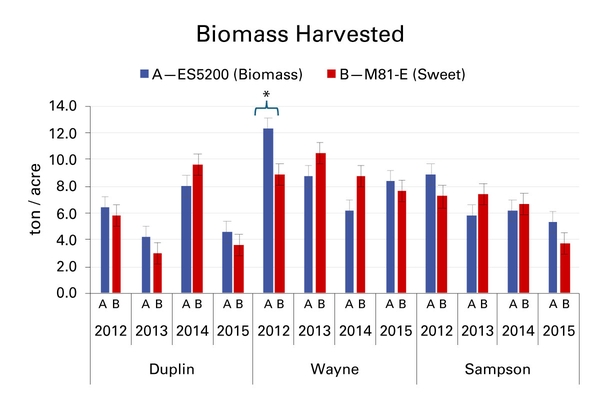

Biomass harvested was similar for both cultivars in sprayfield conditions across years and locations, except for Wayne County in 2012 (Figure 3), where the biomass harvested for ES5200 sorghum was exceptionally high (12 tons per acre). Across location and years, biomass harvested averaged 7 (± 2.0) tons per acre and ranged from 3 to 12 tons per acre (Figure 3). The large variation reflects the variability at sprayfields due to management in terms of nutrient loadings, which were different among locations and varied by year in each location, and environmental conditions at each site. For example, lowest biomass harvested in 2013 and 2015 in Duplin County resulted from abnormally high rainfall (>12 inches) in June (that is, one month after planting), which caused less than ideal conditions for crop establishment and development. In addition, the total nutrient loadings for Duplin 2015 were the lowest (at 36, 6, and 59 pounds per acre for nitrogen, phosphorus, and potassium, respectively) compared to the other years and locations.

Plant heights at harvest time followed the same trend as biomass harvested: the taller the plants, the greater the biomass. Sorghum heights ranged from 9 to 16 feet tall in sprayfield and non-sprayfield areas. On average, the height of sorghum ES5200 was about 2 feet greater than sweet sorghum M81-E. Increasing nitrogen fertilization rate from 0 to 240 pounds per acre resulted in about 1 foot height increase for sorghum ES5200.

Averaged across four years, three locations, and two sorghum cultivars, nutrient removals were 127 (± 63) pounds nitrogen per acre, 27 (± 9) pounds phosphorus per acre, and 283 (± 97) pounds potassium per acre. Due to the high nutrient loading in the sprayfields, these data from the sprayfields most likely represent the maximum nutrient removal values achievable for sorghum in this region.

In non-sprayfield areas, nitrogen fertilizer rate treatments had different effects for each sorghum cultivar. For biomass sorghum ES5200, nitrogen fertilizer addition had a moderate effect on biomass harvested in two years (2012 and 2014) out of a total of four years (2012 to 2015) of experimentation. In 2012 and 2014, the greatest increase in biomass harvested was from 6.5 to 8.3 tons per acre when nitrogen fertilizer rate increased from 0 to 60 pounds per acre. There was no response to nitrogen fertilizer addition for sweet sorghum M81-E, and total biomass harvested ranged from 3.7 to 5 tons per acre.

Partitioning of Biomass Harvested and Nutrient Removal

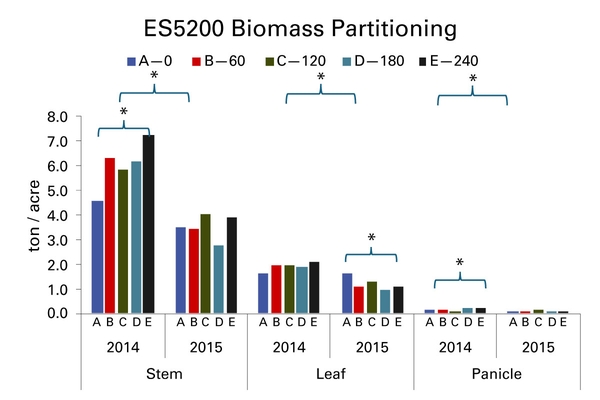

Averaged across N rates, the stem component consistently accounted for 74% in 2014 and 73% in 2015 of the total crop biomass yield for sorghum ES5200 (Figure 4). The leaf component accounted for 24% and the panicle for the remaining 2%. When biomass increased in 2014 as a function of nitrogen fertilization rates for sorghum ES5200; the stem component accounted for about 81% of the total biomass increase (Figure 4). Increasing rates of nitrogen fertilizer partitioned resources primarily toward the stem component. Greater overall biomass harvested was associated with greater canopy height and stem yield.

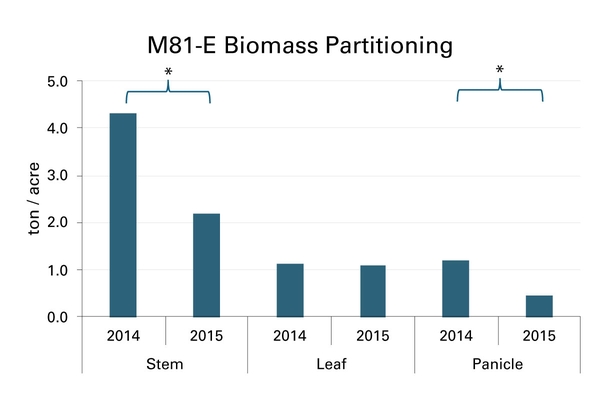

For sweet sorghum M81-E, there was no effect of nitrogen fertilization. No response to nitrogen fertilizer rates, or limited response up to 40 pounds nitrogen per acre, has been reported previously across multiple US locations (Erickson et al. 2012; Han et al. 2012; Heitman et al. 2017b; Wortmann et al. 2010). Averaged across years, the stem, leaf, and panicle components accounted for 63%, 24%, and 13%, respectively, of the total biomass harvested (Figure 5).

Nutrient removal is calculated by multiplying the biomass harvested by the concentration of the nutrient in the harvested plant tissue (Table 1). Considering the total amount of nutrients removed by the three components of biomass (that is, stem, leaf, and panicle), the stem component alone accounted for 55%, 64%, and 84% of the nitrogen, phosphorus, and potassium removals, respectively, for sorghum ES5200. Removal of nutrients in the panicle was ≤5%. In contrast, the panicle in sweet sorghum M81-E accounted for 29%, 45%, and 8% of the total nitrogen, phosphorus, and potassium removed, respectively. The stem component for sweet sorghum M81-E accounted for 40%, 25%, and 76% of the total nitrogen, phosphorus, and potassium removed, respectively.

| Sorghum | Component | N removal | P removal | K removal |

|---|---|---|---|---|

| lb per acre [a] | ||||

| ES5200 | Stem | 48 | 10 | 109 |

| Leaf | 35 | 5 | 19 | |

| Panicle | 5 | 1 | 2 | |

| M81-E | Stem | 29 | 2 | 84 |

| Leaf | 22 | 3 | 18 | |

| Panicle | 21 | 4 | 8 | |

[a] Data are mean values of two years. ↲

Summary

High biomass produced by both sorghums and collected in a single clipping event supports the use of sorghum as a dedicated bioenergy crop. Nevertheless, the relatively low nutrient removal rates, especially for nitrogen (that is, ≤ 88 pounds per acre), compared to bermudagrass cropping systems currently used in sprayfields (nitrogen removal of 270 pounds per acre) may limit sorghum use in nutrient-rich environments such as sprayfields. If sorghum is to be the only crop grown during the season, then irrigation management and nutrient loading will need to be less intensive (lower amounts) compared to current bermudagrass-based systems to prevent soil nutrient accumulation. Sorghum-based double-cropping systems that incorporate a cool season crop could potentially help offset nutrient loadings, but data are limited on sprayfield environments at this point.

Across years, the proportion of biomass harvested by component (that is, stem, leaf, and panicle) was more consistent compared to the numerical values, which varied by year. The effect of nitrogen fertilization varied by sorghum cultivar. Adding nitrogen fertilizer increased biomass harvested only for sorghum ES5200. The increase resulted from resources partitioned primarily toward the stem component. There was no effect of nitrogen fertilization for sweet sorghum M81-E. Nutrient removals followed the trend of stem>leaf>panicle.

References

Erickson, J.E., K.R. Woodard, and L.E. Sollenberger. 2012. “Optimizing Sweet Sorghum Production for Biofuel in the Southeastern USA Through Nitrogen Fertilization and Top Content.” BioEnergy Res. 5:86–94. ↲

Han, K.J., W.D. Pitman, M.W. Alison, D.L. Harrell, H.P. Viator, M.E. McCormick, K.A. Gravois, M. Kim, and D.F. Day. 2012. “Agronomic Considerations for Sweet Sorghum Biofuel Production in the South-Central USA.” BioEnergy Res. 5:748–758. ↲

Heitman, A.J, M.S. Castillo, T.J. Smyth, C.R. Crozier, Z. Wang, and R.J. Gehl. 2017a. “Biomass and Sweet Sorghum Fertilized with Swine Lagoon Effluent for Bioenergy.” Agron. J.

Heitman, A.J., M.S. Castillo, T.J. Smyth, C.R. Crozier, Z. Wang, R.W. Heiniger, and R.J. Gehl. 2017b. “Nitrogen Fertilization Effects on Yield and Nutrient Removal of Biomass and Sweet Sorghum.” Agron. J. ↲

Heitman, A.J., M.S. Castillo, T.J. Smyth, and C.R. Crozier. 2018. “Stem, Leaf, and Panicle Yield and Nutrient Content of Biomass and Sweet Sorghum.” Agron. J. ↲

Wortmann, C.S., A.J. Liska, R.B. Ferguson, D.J. Lyon, R.N. Klein, and I. Dweikat. 2010. “Dryland Performance of Sweet Sorghum and Grain Crops for Biofuel in Nebraska.” Agron. J. 102:319–326. ↲

Publication date: Nov. 26, 2024

AG-978

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.