Subsurface drip irrigation (SDI) is a relatively new system that may give North Carolina producers similar or higher crop yields while using less water than other irrigation systems. Proper site selection helps ensure optimum system performance and crop yield while minimizing expenses. This publication will help you consider the characteristics of your field, soil, crop, cropping system, and irrigation water resources as they apply to SDI. Managerial and farm labor resources, economic factors, and industry support infrastructure are also discussed, as they affect your decision about the appropriateness of SDI in your situation.

Introduction

Irrigation is commonly needed in North Carolina despite the fact that average annual rainfall exceeds the amount of moisture that evaporates from fields and is used by crops, evapotranspiration (ET). Rain doesn’t always fall when and where it is needed, and sandy soils, such as those found in the coastal plain, have a limited capacity for holding water. To avoid potential economic loss from under- or over-irrigation, growers need an irrigation system that applies water uniformly and efficiently.

To decide if SDI is the right system for your site, you need to carefully consider and weigh it against other alternative systems. The water supply and pumping considerations; soil considerations; field size, shape, and topography; producer preferences, practices and experiences; crops and cropping systems; and maintenance aspects all affect the ultimate economic success or failure of an SDI system on your farm. While each of the pros and cons of a SDI system may not apply to your situation, it is useful to recognize that they can occur. A review of SDI advantages and disadvantages is provided by Lamm, (2002). Fail to recognize a significant constraint or to give too much weight to a positive aspect and you may end up with a poorly adapted system. This publication gives you a brief overview of the most crucial considerations, and provides good primary information if you are considering SDI.

Water Supply and Pumping Considerations

The water supply is often the limiting factor in determining whether irrigation is appropriate for a particular farm. How much good quality water can your potential water supply provide? Volume criteria include the flow rate that can be sustained and the reliability of the water supply, both during a growing season and over a number of years. A lake or pond that is filled by the surrounding watershed should be able to store the water needed for irrigation, but there may not be enough rainfall to refill the pond during the growing season. During a dry year, you will need an additional water source. This can be surface water from a river or stream or groundwater from a well. A well can supply an ample volume of water, but the flow rate can be limited by the characteristics of the aquifer and/or by the size of the well. Surface and groundwater supplies may also diminish or fail during drought, just when you most need the water. Many water supplies are replenished annually, but if rainfall is low for several years, some water supplies will continue to decline. You must design an irrigation system based on the water supply flow rate for the most probable limiting condition, considering both flow rate and reliability.

The quality of the source water must also be a prime consideration for an SDI system. If the water is not clean, emitters will clog. Algae and sediment are common problems in surface water sources. Dissolved iron, manganese, sulfur, and carbonates are common problems in groundwater. You may need to filter and/or chemically treat your water before it is suitable for SDI. The cost and effort associated with treating water is a key consideration for determining the potential for SDI.

Creeks and streams are often used for irrigation. However, these are flowing water sources and, therefore, have very limited storage. The stream flow must be greater than the pumping rate of the irrigation system at all times to make the source useful for irrigation. The maximum rate of water use by crops in North Carolina can approach 0.25 inches per day. Since irrigation systems are not 100 percent efficient, water must be applied at a rate greater than the crop use rate to prevent crop water stress. You will need to supply a flow rate of 12 gallons per minute (gpm) for each acre irrigated if you plan on running your system 12 hours per day; more if you will operate it fewer hours and less if you will operate it more hours.

The required pumping flow rate mentioned above needs to be matched with the SDI system flow rate. The system flow rate is a function of the dripline output, dripline spacing, and the area irrigated. For example, if the dripline is rated at 0.45 gpm per 100 feet of dripline, and the dripline is placed on a 6-foot spacing (7,260 feet of dripline per acre), then the water source will need to provide 32 gpm for each acre irrigated at one time. If you plan on operating your system 12 hours per day, this means that the SDI system would need to be divided into three zones (32 gpm is about three times 12 gpm). For small fields, it may be impractical to divide the SDI system into zones, and you would need to provide the full system flow rate (32 gpm per acre in this example). If one-half inch of water is to be applied during each irrigation event, then 7 hours are needed per set (zone) in this example.

If you have a relatively shallow and adequate aquifer below your field, groundwater will normally be your first choice as a water supply for SDI. Get information about the likelihood of finding an adequate groundwater supply from regional offices of the United States Geologic Survey (USGS) in Asheville, Charlotte, or Raleigh. Local well drillers can also help evaluate an area for potential well development. Drilling a well can be expensive. Cost depends on aquifer depth, borehole diameter, and casing material. Additional costs include the pump and power source and any needed permits. The availability of energy sources for pumping can be an important factor in site selection. Electric motors larger than about 10 horsepower used to power irrigation pumps normally require three-phase electricity that may not be available in rural areas. Pumps powered by petroleum-based engines may have limited options for automation, and they can be more costly to operate. In most situations, a high-production well must be drilled deep into the aquifer and have a large diameter borehole. A series of low-capacity wells may cost less to install than one well, but the hydraulic system must be carefully designed to ensure an efficient pumping system. A system with multiple wells can lower the overall risk to the crop when one pump needs repair.

Ponds, lakes, rivers, and streams are excellent sources of irrigation water when they are near the field. If the source is not adjacent to the field, then the cost of moving water can be prohibitive. Pressurized pipe conveyance has two significant costs: the purchase and installation of the pipe and pump, and the annual energy cost of operating the pump.

Water harvesting may provide another source of water. Water harvesting is the process of collecting water when it is available and storing it until needed. Embankment ponds built in the lower parts of watersheds are examples of water harvesting. The stored water then augments another water source. A common example is a low-production well with inadequate flow rate for irrigation that is used to fill a pond in between irrigation events. Then you can irrigate from the pond.

Groundwater is often of very high quality, which can reduce the cost of filtration for an SDI system. However, you need to check for high concentrations of dissolved ions, such as iron, manganese, or sulfur. These ions can be oxidized by bacteria and form slimes. Iron, manganese, and calcium can also form mineral precipitates (scale) when oxidized. The pH and level of alkalinity are also important, and indicate whether a scaling problem is likely to occur. Water treatment may be required to prevent mineral precipitants from forming. (Pitts et al., 1990)

Ponds, lakes, and slow-moving streams will tend to have high concentrations of algae, suspended solids, and floating debris. Fast-moving streams may have higher sediment loads after a storm. Sand media filters and/or disc filters are recommended for removing heavy concentrations of algae and suspended solids. Filtration will improve the water quality, but filters must be properly sized and routinely flushed and maintained. Generally speaking, the quality of surface water will be poor compared to groundwater, and thus require more filtration. Effluent from municipalities might also be a source of irrigation water. Using effluent for irrigation has three positive features:

-

It is a source of water,

-

It can provide some of the crop nutrients, and

-

The soil provides additional water treatment of the effluent as it percolates through the soil.

There are also some drawbacks that must be addressed:

-

Effluent can contain high nutrient levels that may cause microbial growth in driplines.

-

Treatment plant effluent may need additional filtration, chemical treatment, and possible disinfection to protect workers.

-

Reuse of treated wastewater may be restricted to use on certain crops. Guidelines on water reuse vary by state (USEPA, 2004).

Whatever the source of water for an SDI system, the water must be clean or emitters can become clogged by material suspended in the water, precipitation of dissolved minerals in the water, and biological material. Determine the water treatment needed by considering the severity of the clogging potential and/or the water quality hazard to the crop. In general, you can use water treatment to filter out physical and biological solids, and to change the water chemistry.

Soil Considerations

Soil type is a primary consideration for designing and implementing SDI. Generally, driplines can be deeper and spaced farther apart on heavier soils. In recent studies on sandy soil, Dukes and Scholberg (2005) reported a dripline spacing of 2.5 feet and depth of 9 inches was optimum for sweet corn production. Grabow et al. (2006) found that a 6-foot dripline spacing and 9-inch depth for cotton production in a sandy loam soil worked well, while up to a 7.5 foot-dripline spacing at a 12-inch depth was found to work for field corn in a clay loam soil in the Piedmont of North Carolina (Grabow, et al., 2003). The shallow depth required for SDI on coarse soils of the coastal plain prevents deep tillage and can lead to compaction (Camp et al., 1999). Water holding capacity of the soil is an important factor in site selection as it affects irrigation frequency and amount.

Understanding how water is held and moves through the soil allows you to make an educated decision about the depth of placement and the spacing of the driplines in your particular fields. For narrowly spaced row crops, such as corn and soybeans, your goal is to have a nearly continuous wetted-zone beneath the surface. For crops grown in widely spaced rows, such as fruits and vegetables, the wetted zone is usually about half the distance between rows, or less for coarse soils.

The upward movement of water depends on the soil’s texture. Courser soils will provide less upward water movement. Shallow placement is recommended if irrigation is needed for seed germination on coarse soils. Shallow placement also allows more of the root zone to be filled with water, so you can irrigate less frequently. Deep installations may not require any changes in cultural practices (except for deep ripping). This installation may limit your ability to rotate shallow-rooted crops and will not provide water to establish crops on coarse soils where vertical movement is limited.

Field Size, Shape, and Topography

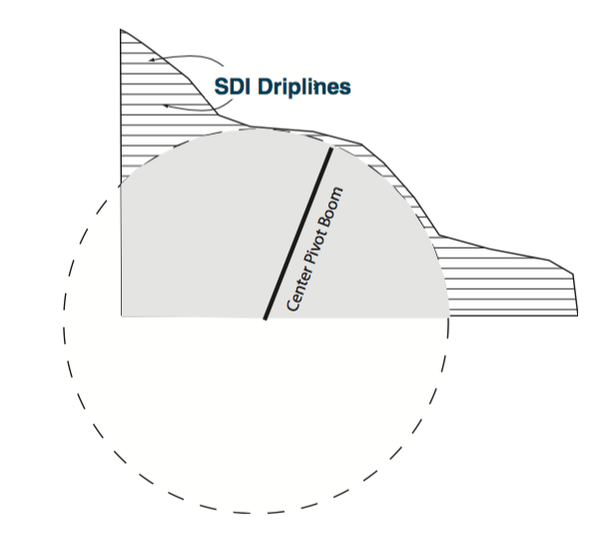

Many North Carolina producers increased irrigation efficiency by moving to center pivot sprinkler irrigation. However, irregular field shape and sizes limit the use of center pivot irrigation. SDI can be adapted to your field and water resource constraints. While the cost per acre of a center pivot sprinkler system increases rapidly if your field size is less than 100 acres, SDI systems are less subject to increasing per acre costs as field size decreases (Bosch, et al. 1992, O’Brien et al. 1998).

The field size, shape, and topography (along with peak crop water use rates and dripline hydraulic characteristics) will also help determine the number of irrigation zones. Designing a system that uses fewer zones than determined from matching pumping requirements to system requirements as discussed earlier may result in a system that is more economical to install and operate; however, you must keep in mind that fewer zones will increase pump and mainline costs. Therefore, it is wise to consider the effect of system layout, component selection, and field parameters carefully.

Topography can complicate system design and limit feasibility of SDI. Whenever possible, install dripline laterals downslope on slopes of less than 2 percent (Lamm et al., 2003). A pressure change of approximately 20 percent along the dripline will result in a flow change of approximately 10 percent. A maximum of 10 percent flow change is the generally acceptable maximum flow variation along the lateral (Bralts et al., 1987). On steeper terrain, place the driplines along the field contour and/or use dripline with pressure compensating emitters. Dripline with pressure compensating emitters is more expensive which may limit use of SDI for commodity-type crops (e.g. corn, soybeans, cotton, and peanuts). Shorter dripline runs can also help control pressure, but they will decrease zone size and increase the overall number of zones unless driplines run in both directions from the manifold.

Field slope may also cause inadvertent backsiphoning when the SDI system is shut down. You may need to place check valves, air vents, and vacuum breakers at various points in the SDI system to keep chemically treated water out of the water supply and also to keep soil from being sucked into the driplines when the system is shut down. Preventing backsiphoning into dripline laterals can be expensive on undulating slopes and may limit your use of SDI if the backsiphoning hazard is great.

Producer Preferences, Practices, and Experiences

When considering SDI, you must first consider the size of the system to be installed and if the system will be expanded in the future. You need design, installation, and management criteria for your soil, crop, climate, market, etc. Needs vary considerably among sites. Since SDI is relatively new to North Carolina and there are few commercial SDI systems to base success on, it may be prudent to start with a smaller SDI system to reduce risk. Based on experience with the smaller system, the design and management criteria could be modi ed before investing resources in a larger system.

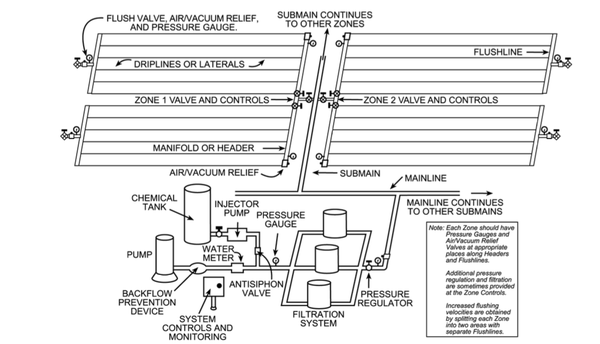

Also consider how much time you and your farm’s management staff will have to learn the proper operation and maintenance of a new technology. You will need to familiarize yourself with the basic components of an SDI system (Figure 3). Required components include a pump and motor, a filtration system, distribution pipe (i.e. PVC mains, submains, and manifolds), driplines, control valves, and pressure regulators. Since SDI systems are buried, you won’t be able to visually inspect many system components to assess their operation. When placed in strategic locations, flowmeter readings and pressure measurements can be used to monitor your system to maintain peak system performance. SDI systems are often connected to manifolds at the end off the dripline to facilitate flushing. If fertilizers are to be injected, fertilizer containment, an injection system, and proper backflow prevention are required. You can automate the system by adding an irrigation controller and automatic (solenoid or hydraulic) valves. This can reduce the labor requirements and possibly increase the system efficiency. The inability to visually evaluate and have confidence in SDI performance has limited its adoption for high-value crops in some areas of the country. Growers adopting SDI must adopt rigid and consistent strategies to evaluate performance and make timely adjustments to ensure high crop yields and long SDI system life. Are you willing to take this on? Additional design information can be found in Rogers et al. (2003) and Lamm et al. (2003).

Crops and Cropping Systems

Many of the North Carolina crops suitable for irrigation are also suitable for SDI. Some crops may even be better suited for SDI than for other irrigation methods. For example, melons produced on bare soil are less susceptible to diseases and some rotting problems because the soil surface remains drier with SDI. However, this benefit would be minimal in wet years and/or if you use plasticulture for crop production. The drier soil surface may cause pegging problems in peanuts, and a sprinkler irrigation may be better for temperature moderation and movement of calcium (plaster) into the pegging zone. You may need to adjust and control tillage and planting patterns to ensure proper irrigation distribution to the plants and to avoid damaging the SDI system. A more comprehensive discussion of the many crops suitable for SDI lies beyond the scope of this publication, but additional discussion can be found in Camp (1998).

Subsurface drip irrigation is not a new technology, but it is not widely used in North Carolina. Producers are apprehensive about SDI because the lines are buried and water cannot be seen. The success of a SDI system depends on good design, proper installation, and regular maintenance. A knowledgeable consultant can be a deciding factor as you explore the suitability of a SDI for your farm.

When compared with surface or sprinkler irrigation systems, you will find time lags associated with applying irrigation water, and water will be applied to a smaller portion of the root zone. Delay can prove costly, so the need to irrigate must be anticipated. This situation is compounded if you have sandy soils with a low water-holding capacity or are growing crops with a shallow root zone.

Looking at plants to see if they need water may not be sufficient. Irrigations should be scheduled based on the soil moisture status. Three procedures may be used:

- A checkbook method based on the estimated crop water use rate, irrigation and rainfall, and the soil’s water holding capacity, such as that found in Evans et al. (1991),

- Direct measurement of soil moisture water with instrumentation (Munoz-Carpena et al, 2006; Evans et al., 1991), and

- A combination of soil water status instrumentation used with a water balance procedure.

These procedures require knowledge of your crop’s water requirements and root-zone depth, your soil’s water-holding capacity, and your irrigation system capabilities in order to schedule irrigations effectively.

Maintenance

SDI systems may be damaged by insects, rodents, and other animals, especially when they chew through thin-walled drip tubing seeking water during a drought. Pest control programs are essential. Repair is costly and labor-intensive. Discussion of pest problems in regions like North Carolina can be found in Stansly and Pitts (1990), Childers et al. (1992), and Boman and Bullock (1994).

Your primary challenges will be to keep the emitter devices from clogging and roots out of the drip tubing. Internal clogging, caused primarily by sediment, algae, and bacterial slime can usually be effectively controlled by proper filtration, emitters with larger discharge orifices and flow paths, and proper chlorination of the SDI system.

Root intrusion into the drip tubing tends to occur when there is crop water stress. To prevent root intrusion, limit crop water stress by saturating the root zone around the emitter, or use dripline that incorporates physical barriers at the emitter and/or has herbicides impregnated in the dripline. Chemical injection of herbicide can also help prevent root intrusion. Be sure to follow State of North Carolina guidelines and label recommendations when injecting chemicals.

Chemical treatment of the irrigation water is often required to keep microbial growth and/or mineral precipitation from clogging emitters. Generally, you can control microbial activity with chlorine, and acid injection can remove scale deposits, reduce or eliminate mineral precipitation, and make the environment unsuitable for microbial growth.

Summary

What must you take into account when considering a site for subsurface drip irrigation? Consider your soil. The majority of soils on the Coastal Plain are sandy loam and are fairly coarse and require driplines to be placed at shallow depths. This will require shallow cultivation, which could lead to compacted soil and reduced crop performance. You may also face increased maintenance from tillage if not careful. When using surface water in warmer areas of the state, excess biological growth within the dripline can result in clogging, and insects and other pests may damage driplines. The relatively high mineral content and pH of most groundwater in North Carolina can clog driplines, so you may need the extra expense of water treatment. But perhaps your largest challenge will be management. You will need to manage something you cannot directly observe. This requires more effort managing water filtration and monitoring the system with water meters and pressure gauges.

References

Alam, M., T.P. Trooien, F.R. Lamm, and D.H. Rogers. 2002. Filtration and maintenance considerations for subsurface drip irrigation (SDI) systems. Kansas State University Cooperative Extension Irrigation Management Series, MF-2361. Revised. 4pp. (Accessed Feb. 9, 2005)

Boman, B. J. and R. C. Bullock. 1994. Damage to microsprinkler riser assemblies from Selenisa sueroides caterpillars. Applied Engineering in Agriculture, 10(2):221-223.

Bosch, D. J., N. L. Powell, and F. S. Wright. 1992. An economic comparison of subsurface microirrigation with center pivot sprinkler irrigation. Journal of Production Agriculture, 5(4):431-437.

Bralts, V.F., D.M. Edwards, and I.P. Wu. 1987. Drip irrigation design and evaluation based on the statistical uniformity concept. Advances in Irrigation, 4:67-117.

Camp, C.R. 1998. Subsurface drip irrigation: A review. Transactions ASAE, 41(50):1353-1367.

Camp, C.R., P.J. Bauer, and W.J. Busscher. 1999. Evaluation of no-tillage crop production with subsurface drip irrigation on soils with compacted layers. Transactions ASAE, 42(4):911-917.

Childers, C. C., S. H. Futch, and L. A. Stange. 1992. Insect (Neuroptera: Lepidoptera) clogging of a microsprinkler irrigation system in Florida citrus. Florida Entomology 75(4): 601-604.

Dukes, M.D. and J.M. Scholberg. 2005. Soil moisture controlled subsurface drip irrigation on sandy soils. Applied Engineering in Agriculture, 21(1):89-101.

Evans, R. O., R. E. Sneed and D. K. Cassel. 1991. Irrigation scheduling to improve water and energy use efficiencies. AG-452-4. North Carolina Cooperative Extension.

Evans, R. O., D. K. Cassel and R. E. Sneed. 1991. Measuring soil-water for irrigation scheduling: Monitoring methods and devices. AG-452-2. North Carolina Cooperative Extension.

Grabow, G. L., R.L. Huffman, R.O. Evans, D. L Jordan, and R.C. Nuti. 2006. Water Distribution from a Subsurface Drip Irrigation System and Dripline Spacing Effect on Cotton Yield and Water Use Efficiency in a Coastal Plain Soil. Transactions of the ASABE 49(6): 1823-1835

Grabow, G.L. Rodney L. Huffman, and Robert O. Evans. 2003. Testing the Effect of Subsurface Drip Line Spacing on Corn and Soybean Yield, Presented at the Fourteenth Annual Joint Conference & Agricultural Expo, Sheraton Imperial Hotel, New Bern, NC., Jan. 15-16.

Lamm, F. R., 2002. Advantages and disadvantages of subsurface drip irrigation. In Proc. International Meeting on Advances in Drip/Micro Irrigation, Puerto de La Cruz, Tenerife, Canary Islands, December 2-5, 2002. Instituto Canario de Investigaciones Agrarias, Canary Islands. 13 pp. (Accessed Feb. 2, 2005).

Lamm, F. R., D. H. Rogers, M. Alam and G. A. Clark. 2003. Design considerations for subsurface drip irrigation (SDI) systems. KSU Cooperative Extension Irrigation Management series, MF-2578. 8 pp. (Accessed Feb. 2, 2005)

Munoz-Carpena, R., S. Shukla, and K. Morgan. 2007. Field devices for measuring soil water content. Southern Regional Water Quality Program. Cooperative States Research, Extension and Education System, United States Department of Agriculture.

O’Brien, D. M., D. H. Rogers, F. R. Lamm, and G. A. Clark. 1998. An economic comparison of subsurface drip and center pivot sprinkler irrigation systems. Applied Engineering in Agriculture, 14(4):391-398.

Pitts, D.J., D.Z. Haman, and A.G. Smajstrla. 1990. Causes and prevention of emitter plugging in microirrgation systems. Bulletin 258, Florida Cooperative Extension Service, Institute of Food and Agricultural Science, University of Florida, Gainesville, FL. (Accessed Feb. 9, 2005)

Rogers, D. H., F. R. Lamm, and M. Alam. 2003. Subsurface drip irrigation (SDI) components: Minimum requirements. KSU Cooperative Ext. Irrigation Management Series, MF-2576. 4 pp. (Accessed Feb. 2, 2005)

Stansly, P. A., and D. J. Pitts. 1990. Pest damage to micro-irrigation tubing: Causes and prevention. Proceedings of the Florida Horticultural Society, 103:137-139.

USEPA. 2004 Guidelines for water reuse. 2004. Prepared for USEPA and USAID by Camp, Dresser & McKee, Inc. September.

Wade, H., D. Seal, C. Clark, B. Walls, K. Messick and G. Grabow. 2003. Chemigation and fertigation: Anti-pollution devices for irrigation systems. Prepared by North Carolina Department of Agriculture & Consumer Services and North Carolina State University.

Other publications in the Subsurface Drip Irrigation series available:

Acknowlegments

Contributions to this fact sheet were made by faculty of the Cooperative Extension Service, the Agricultural Experiment Stations and universities in Arkansas, Florida, Georgia, Kansas, Louisiana, Maryland, North Carolina, South Carolina and Tennessee, and the USDA-ARS in Georgia and South Carolina. Activities that resulted in the publication of this document and the companion documents listed were supported by the CSREES multi-state project S-1018, "Irrigation Management for Humid and Sub-Humid Areas" and the ASCE/EWRI Irrigation and Drainage Council-On-Farm Irrigation Committee-Task Committee on "Subsurface Drip Irrigation Application for Humid Regions."

Publication date: Feb. 1, 2008

Reviewed/Revised: May 22, 2024

AG-695-02

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.