Introduction

Sediment traps and basins at construction sites, agricultural operations, and other unsettled areas provide temporary pools for runoff that allow sediment to settle before the water is discharged into a river, stream, or landscape. They prevent erosion and trap sediment and other coarse material. They are most effective in sandy soils and less effective in clayey soils. Unfortunately, these traps and basins are not efficient when the swift, turbulent water moves along a straight-line flow that takes runoff quickly to the basin’s outlet. This short-circuits interaction with the entire basin. Using baffles to slow, calm, and distribute the water can help solve this problem. Baffles can lengthen the flow path and distribute the flow more widely. They significantly increase the amount of sediment captured and also trap much smaller particles than open basins.

The Flow Path

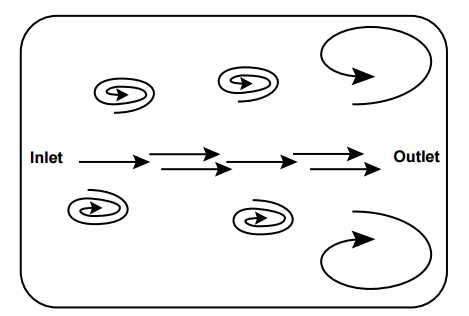

The typical flow in an open basin receiving peak-period, high-speed runoff is illustrated in Figure 1 (note the high velocity down the middle, as swift water bypasses much of the basin’s breadth. There are significant back flows near the outlet and smaller side eddies in the middle and near the inlet, all of which reduce settling efficiency). The majority of the water entering the basin rushes down the middle from inlet to outlet and does not interact with the entire basin area. Turbulence resulting from the high flow rate gives rise to backflow currents and side eddies, which interfere with the settling process and reduce settling efficiency. Installing either solid or porous baffles can improve the basin’s efficiency. Solid baffles are the simplest to install, but porous baffles are more efficient.

Solid Baffles

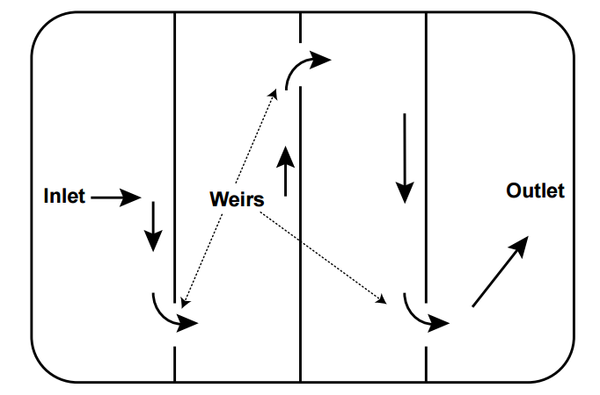

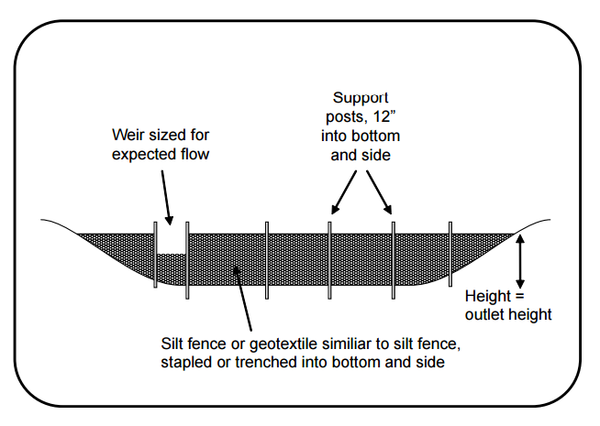

A simple way to lengthen the flow path is to install solid baffles that force the water to move from side to side in the basin (Figure 2). These may be made of sturdy plywood or similar materials, usually with a notch or weir cut into the top at opposite ends to create a long, back-and-forth flow path. Silt fencing (or geotextile) has also been used because the material is sturdy, inexpensive, and easy to install, and it is commonly available on construction sites. The geotextile is essentially impermeable for the kinds of flows expected in the basin. An example of this type of baffle is shown in Figure 3.

The water is forced to follow a longer path than if no baffles were used, thereby creating more time for settling. Moreover, the runoff is exposed to more basin surface, which provides more area for settling of the sediment.

Baffles must be installed correctly to take full advantage of their benefits (Figure 4):

- The weir should be sized to accommodate the effects of the storm for which the basin was designed. For a 1-foot-deep weir, the width of the weir in feet should equal the flow in cubic feet per second divided by 3.

- The weirs should be placed on opposite sides of each other but not too close to the basin’s perimeter to keep the flow through them from eroding the basin’s sides.

- The first bay should be accessible for maintenance, as most of the sediment will accumulate in this area.

Porous Baffles

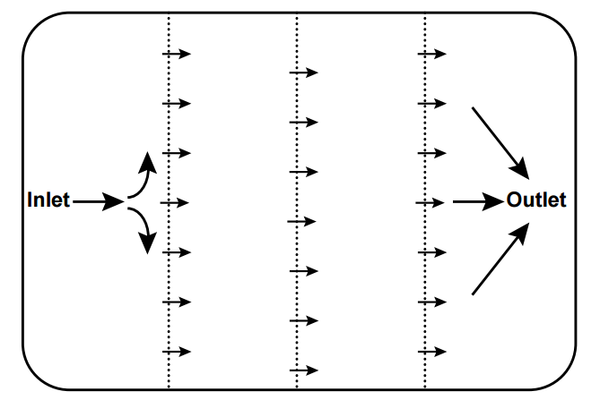

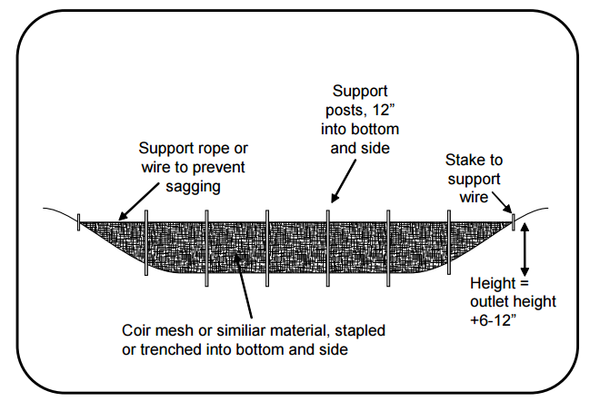

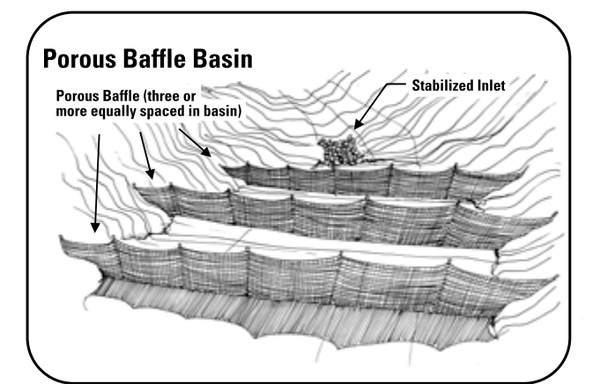

An even more effective way to improve a basin’s efficiency involves using porous baffles to spread the flow over the width of the entire basin. This is accomplished using materials that do not block the water as much as silt fence material does. As the water flows through the baffle material, it is slowed sufficiently to back up the peak flow so it spreads across the entire width of the baffle (Figure 5). Spreading the flow across the full cross section of the basin greatly reduces its speed and turbulence. This combination increases sediment deposition and retention and also decreases the particle size of sediment captured. The installation can be similar to the silt fence baffle but without a weir (Figures 6 and Figure 7). Materials such as jute backed by a coir erosion blanket (Figure 8), coir mesh, and a tree-protection fence folded over to reduce pore size have all been used successfully. Other similar materials could work as well. A silt fence supported by hogwire fencing has been used with slits cut into the material in the middle of each fence opening. A support wire or rope across the top will help prevent excessive sagging if the material is attached to it with strong zip ties or similar fastenings. Another option is to use a sawhorse type of support with the legs stabilized with rebar inserted into the basin floor. These work well, can be prefabricated off site, and can be installed quickly.

Conclusion

Runoff on construction sites often contains large amounts of soil, and trapping it before it leaves the site is critical in preventing damage to streams, rivers, and lakes. Such sediment can have major impacts on the quality of water that humans drink, the habitat of fish and other wildlife, and the overall value of our waterways. Sediment traps and basins are the most common methods of trapping soil on-site, but adding baffles is a demonstrated method of greatly improving their performance.

Reference

Thaxton, C. S., J. Calantoni, and R. A. McLaughlin. 2004. Hydrodynamic assessment of various types of baffles in a sediment detention pond. Transactions of the ASAE. Vol. 47(3): 741-749.

Publication date: March 10, 2015

Reviewed/Revised: March 28, 2025

AG-439-59

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.