Bermudagrass (Cynodon dactylon L.) is a warm-season perennial grass and one of the most important forage and turf species in the southeastern United States. Over the years, acreage of bermudagrass has increased in North Carolina. Most productive during the summer, bermudagrass is a nutritious forage that is well suited for both grazing and hay production, mainly in the coastal plain and piedmont. This publication is primarily for Extension agents and land and livestock managers seeking detailed information about bermudagrass production in the state, including cultivar characteristics, propagation, fertilization, and pest and disease management.

General Characteristics and Adaptation

The botanical characteristics of bermudagrass are variable among cultivars (Taliaferro et al. 2016). Bermudagrass leaf blades are typically 0.06 to 0.13 inch wide and 1.2 to 3.2 inches long, with a hairy ligule (ciliate membrane) at the base. The plants produce both rhizomes and stolons. Stem diameter is variable, ranging from slender to stout; internodes are short (common bermudagrass) to relatively long (Tifton 85). Seedheads form a digitally arranged cluster of three to five thin spikelets 1 to 2.5 inches long. Plants are usually short, ranging from 12 to 25 inches tall.

If drainage is good, bermudagrass will grow well in a variety of soil types, including sand, loam, silt, and clay. It is best suited to well-drained sites; in soils too sandy to realistically produce high yields of row crops or good growth of clover-fescue, bermudagrass thrives. Plants may survive in poorly drained soils, but production potential is limited; bermudagrass is not adapted to wet areas. It grows best at high temperatures (85°F to 95°F); growth is minimal once nighttime temperatures fall below 60°F. Therefore, bermudagrass varieties are best-adapted to the piedmont and coastal plain. Bermudagrass does not grow well in shade. It is drought tolerant, although production decreases during drought conditions. Bermudagrass grows best when soil pH is 5.5 or higher; the ideal range is 5.8 to 6.0 or up to 6.5 if the pasture will be overseeded with legumes.

Besides being widely grown for forage, bermudagrass is also a “nutrient receiver crop” on sprayfields (land receiving swine effluent application) and on fields receiving poultry litter. In the coastal plain, land managers typically allocate 75% to 100% of their sprayfields to bermudagrass. Forage accumulation of bermudagrass grown in sprayfields ranges from 4 to 6 tons per acre (Spearman et al. 2021) and tends to be greater compared to bermudagrass grown in traditional non-sprayfield areas in the piedmont (Burns and Fisher 2008; Burns et al. 2009).

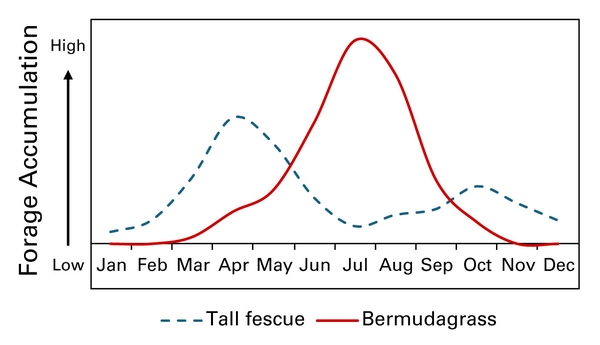

To increase forage production of the farm operation by extending the growing season, bermudagrass fields can be overseeded with annual ryegrass or winter annuals such as rye, oats, wheat, or triticale (Figure 1) (Aiken 2014). Overseeding winter annual grasses into bermudagrass also allows animal manures to be applied during the fall and winter months in North Carolina in the context of farm nutrient management plans. Overseeding alfalfa into bermudagrass is also increasingly popular in North Carolina for hay and grazing in non-sprayfield areas (Figure 2). Hence, bermudagrass cropping systems provide the opportunity for year-round soil cover and year-round forage supply (Figure 3) with minimum tillage because cool-season annual and perennial forages can be no-till planted into established bermudagrass swards (Figure 4).

Bermudagrass Cultivars

Several bermudagrass cultivars are used in the southeastern United States. Bermudagrass cultivars are classified as seeded types and vegetatively propagated types (also known as hybrids). The planting material for the vegetatively propagated types may be tops (that is, aboveground material including stems and leaves) or sprigs.

Sprigs are vegetative plant parts containing stolons, crown buds, and rhizomes or runners dug from an established field. Each sprig can produce a new plant when it is transplanted. Hybrid sprigged-type bermudagrasses are the most common propagation material used in North Carolina, and the major locally available cultivars are Coastal, Tifton 44, Tifton 85, Midland 99, and Ozark. Seeded-type bermudagrass cultivars include Cheyenne, Cheyenne II, Gaucho, Wrangler, Mohawk, Ranchero Frio, and Laredo.

Common bermudagrass has very aggressive growth characteristics and is often a major weed in cultivated crops of the Southeast due to viable seed production. It has relatively low nutritive value and productivity, forms a dense sod, and barely grows over 4 inches tall. It is a common pasture weed that is hard to eradicate selectively. It is still used as a pasture forage crop, however, especially in soils with low fertility and poor management.

Coastal was the first improved bermudagrass, and it has become the industry standard. Its stems, stolons, and rhizomes are larger than those of common bermudagrass, and its internodes are longer. In addition, the light-green leaves of Coastal are more sharply angled to the stem. Coastal bermudagrass produces fewer seed heads than common bermudagrass, and the seeds are sterile, so it must be established from vegetative planting material. In sandy soils, Coastal bermudagrass roots extend deep into the soil profile. When well fertilized, Coastal has nearly three times as many roots below the 4-foot level as common bermudagrass, making it more productive and drought tolerant. Coastal bermudagrass is resistant to the root-knot nematode (Burton and Johnson 1987).

Tifton 44 was released in 1978. It is a hybrid of Coastal bermudagrass and a winter-hardy bermudagrass from Berlin, Germany. Compared to Coastal, Tifton 44 has finer stems, is darker green, and has a more vigorous rhizome and root system, thereby forming a denser sod. On heavy clay soils, Tifton 44 does not spread as rapidly as Coastal or other hybrids. Even though it produces fewer seed heads, Tifton 44 is often confused with common bermudagrass because of its fine stems and leaves. During short dry periods, Tifton 44 rapidly produces seed heads. It also recovers from drought much more slowly than Coastal. Tifton 44 usually begins growing 7 to 14 days earlier than Coastal.

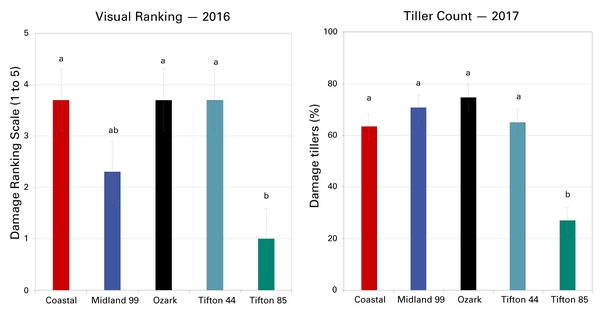

Tifton 85 was released in 1992. Compared to Coastal and Tifton 44, Tifton 85 is taller, has larger stems and wider leaves, and is darker green. Its nutritive value is greater than Coastal. It has a lower cold tolerance than Coastal and Tifton 44. Tifton 85 has large rhizomes and can be established from sprigs or top growth. Tifton 85 usually has greater digestibility than other bermudagrass cultivars and is consistently less affected by stem maggot than Coastal, Midland 99, Ozark, and Tifton 44 (Spearman et al. 2021). The biggest drawback to Tifton 85 compared to other cultivars is its low freeze tolerance (Anderson and Wu 2011). Tifton 85 is recommended for planting solely in the southeastern portion of North Carolina.

Midland 99 was released in 1999. It is tolerant of heavy grazing, low soil pH, and winter stress. Midland is a cross between Coastal and a winter-hardy variety. Productivity is similar to or greater than Tifton 44. Crude protein concentration is comparable to Coastal and Tifton 44. Midland 99 produces seed heads later than most bermudagrass varieties. It is tall and leafy and slightly more winter hardy than Tifton 44. In sprayfields in North Carolina, Midland 99 had greater canopy cover, canopy height, and productivity early in the growing season (first clipping in June to July) compared to Coastal, Ozark, Tifton 44, and Tifton 85; by mid-season, however, these characteristics were similar to other bermudagrass cultivars (Spearman et al. 2021).

Ozark was released in 2002 and is best adapted to sandy loam soils. Very cold-tolerant, Ozark is often recommended for the northern half of the bermudagrass belt, but it can be grown broadly in North Carolina. Productivity of Ozark is similar to Tifton 44. Forage nutritive value of Ozark is similar to or better than other high-yielding bermudagrass varieties. Relatively tall with an upright growth pattern, Ozark has longer leaves compared to Tifton 44.

Newell was released in 2023 by the University of Florida. It was selected based on total productivity and length of the growing season from trials in Florida, Georgia, North Carolina, and Oklahoma. Compared to Tifton 85, Newell has faster establishment, about 15% greater dry-matter productivity, and similar tolerance to bermudagrass stem maggot (Rios et al. 2023). Current planted area is limited across Florida and the Southeast. Although experimental plots in North Carolina were part of the evaluation trials that led to the release of Newell, more research is needed to assess its suitability for this region.

Cheyenne was released in 1989. It is a seeded bermudagrass with a nutritive value similar to Coastal. Cheyenne has exceptionally good persistence, is winter hardy, and quick to establish. Cheyenne has not been a good seed producer, and availability has been limited. Cheyenne II was released from improved selections of Cheyenne. Cheyenne II is now sold and used in seed blends such as Ranchero Frio.

Wrangler was released in 1999. It is a seeded bermudagrass. It is cold hardy and has good cover during the establishment year. Based on trials in Georgia and North Carolina, persistence has been an issue with Wrangler.

CD90160 is a seeded bermudagrass. It is most often sold in seed blends, including Vaquero, Gaucho, Sungrazer Plus, and Sungrazer 777. When grown alone, CD90160 matches the yield, winter hardiness, and persistence of Cheyenne. This cultivar has also demonstrated higher protein and digestible nutrients than Cheyenne.

Gaucho is a seeded bermudagrass that is a blend of CD90160 and Ranchero.

Mohawk is a seeded bermudagrass. It was developed from a turfgrass variety to provide improved coverage and cold tolerance. Mohawk showed cold tolerance in trials in Virginia.

Many blends are available, including two in North Carolina—Ranchero Frio and Laredo. Evaluate the blend to make sure it is recommended for your area.

Establishment

The keys to successful establishment include proper soil preparation, adequate moisture, and weed management. Fields should be fertile, free of weeds, and have a firm, moist seedbed, and the soil pH should be above 5.5. If soil pH is below 5.5, incorporate lime six months prior to planting to allow time for the soil pH to adjust to the desired level. Apply fertilizers according to soil test recommendations. Test the soil regularly (annually or every two years) as part of your field management program. Apply phosphorus and other nutrients only if recommended by the soil report.

For nitrogen fertilization recommendations (which are not provided by the soil test report in North Carolina), consult the North Carolina Realistic Yield Database. This online tool allows you to select your county and soil type, and then provides data for that specific soil, such as Realistic Annual Yield, Realistic Nitrogen Rate, and Estimated Phosphorus Removal. Once the plants start to spread by elongation of stolons (also known as runners) at about six to eight weeks after growth begins, apply 45 to 60 pounds of nitrogen per acre. If moisture and nitrogen are readily available and weeds are controlled, bermudagrass will achieve full ground cover by the end of the year it was established (Spearman et al. 2021).

For planting dates and rates, see AG-266, Planting Guide for Forage Crops in North Carolina. The guide is also available as an interactive online tool; when you select your county and type of crop (or time of year), the tool will provide specific recommendations for planting dates and rates. Recommended planting rates are 6 to 8 pounds per acre (on a pure live seed basis) when seed is broadcast and 10 to 15 pounds per acre when seed is drilled (4- to 9-inch rows) to 0.25 to 0.5 inch deep. Sprigs should be planted at a rate of 40 to 60 bushels per acre.

Sprigging bermudagrass is generally considered more expensive than establishing bermudagrass from seed; however, sprigging offers some advantages. First, herbicides are available for weed control during early vegetative establishment. The lack of effective weed control is a serious issue when establishing seed-type varieties, as stands can be lost to weed competition during the first year. Second, many available sprig-planted bermudagrass hybrids were developed in the South and may be better adapted to our environment. Seeding, on the other hand, is usually less expensive, and it may be easier to find a source of seeds.

Establishment by Seed

Seeded bermudagrass should be established into a well-packed, clean-tilled seedbed. Prepare the ground as early as possible in the spring to allow the soil to settle. To establish a weed-free seedbed, weeds can be sprayed with glyphosate (for example, Roundup) or paraquat (for example, Gramoxone Max). Do not disturb the soil after spraying weeds. Seed can be broadcast and cultipacked into a firm seedbed. To confirm that the seedbed is firm enough, walk across the field and observe footprint depth. If your boot sinks deeper than 1/8 inch, the soil is not firm enough. Seeds can also be planted using a no-till drill. It is recommended to sow seed when the soil temperature at 4 inches deep is 65°F or higher (usually around early May in North Carolina).

Establishment by Sprigs

To avoid contamination by common bermudagrass, other unwanted grass species, and noxious broadleaf weeds, we recommend planting certified sprigs. Certified sprig fields are inspected annually by the North Carolina Crop Improvement Association (NCCIA) to verify that plants are true to variety and have minimal weed content. The NCCIA website lists sources of certified sprigs. There may be well-known, very reputable spriggers in your area who are not certified; know the quality of the stock before you plant. Sprigs are measured and sold by the bushel or cubic foot. One bushel equals about 1.25 cubic feet and contains about 1,000 sprigs. Certified sprigs of Coastal, Tifton 44, Tifton 85, Midland 99, and Ozark are available in North Carolina.

The two methods for sprigging bermudagrass are dormant sprigging and spring sprigging. Dormant sprigging is done in the winter (February to early March), when the plants have not yet begun to grow. Planting dormant sprigs generally allows for quicker coverage in the establishment year. Sprigging in mid- to late-spring (April to June) can be successful if moisture is adequate. Sprigging can be successful even as late as midsummer. Plantings after late June, however, are more likely to encounter moisture deficit, heat stress, weed competition, and freezing of poorly developed root systems during the first winter.

Plant hybrid bermudagrass sprigs into a moist, clean-tilled, firm seedbed at a rate of 40 to 60 bushels of sprigs per acre. Regardless of establishment method, it is very important to firm the soil around the sprig to maintain sprig-to-soil contact, retain soil moisture, and improve sprig survival. Planting with a commercial sprigger generally produces the best results (Figure 5). The sprigger machine cuts a shallow furrow, drops the sprigs 2 to 3 inches deep, and firms the soil over the sprigs with press wheels. You can also broadcast sprigs onto the soil surface with a manure spreader or by hand. Press the sprigs into the soil using a disk with its blades set to cover lightly. After disking, firm the soil around the sprigs with a cultipacker. Cultipacking after sprigs are planted promotes contact of roots with the soil and leaves a smooth surface that is less prone to erosion if heavy rains follow planting. Do not cover sprigs with more than 3 inches of soil or they may not survive.

Plant sprigs as soon as possible after they are dug to maintain quality. If planting must be delayed, store sprigs in a cool, moist place for no more than 24 hours. Sprigs quickly lose their viability if exposed to high ambient temperatures and low moisture. Sprigs allowed to dry or exposed to sunshine for several hours will have decreased viability. Avoid harvesting sprigs two days after a late freeze because of decreased viability.

Sometimes farmers purchase certified sprigs to establish a 1- to 2-acre nursery. The following spring, nursery-grown sprigs are harvested and used to plant larger acreage. Establish nurseries in fields that are free of common bermudagrass and weeds. Digging machines are available to harvest sprigs; an alternative method is to cross-disk to break into small sprigs and then cultivate with a spring-tooth harrow to bring sprigs to the surface. You can use a hay rake to shake the soil from the roots and make it easier to pick up the sprigs.

Establishment by Top Growth or Cuttings

Fresh, aboveground cuttings or clippings can be planted to establish some varieties, including Tifton 85 and Coastal. To establish from cuttings, green top growth is cut like hay, gathered, and quickly spread over the seedbed and lightly incorporated into the soil. Fresh cuttings should be planted the same day they are cut to achieve the best results. Bermudagrass intended for cuttings should be six to eight weeks old and have several nodes on each stem. Cuttings can be spread in rows or broadcast with a manure spreader. Incorporate the cuttings with a disk to cover nodes on the stems. Firm the soil with a cultipacker or field roller after disking to improve soil contact. This technique is inexpensive but could potentially fail more often than sprigging if moisture is restricted after planting. Irrigation when conditions turn dry is strongly recommended.

Weed Management During Establishment

Management of weed pressure during the establishment phase is essential. Try to plant in fields that are relatively free of weeds. Newly established bermudagrass cannot compete with rapidly growing annual grasses and broadleaf weeds. A thick cover of weeds slows stand establishment by shading the emerging bermudagrass and prevents the stolons from pegging down.

Diuron (Direx), a pre-emergent herbicide, can be used only on newly sprigged bermudagrass (not seeded plants or tops) to help reduce weed competition. Diuron applications provide fair to good control of crabgrass, crowfootgrass, and goosegrass and provide residual control of certain annual broadleaf weeds. Diuron should be applied immediately after sprigging before weeds emerge. Do not graze or feed treated foliage for 70 days after diuron application. After emergence, most broadleaf weeds can be controlled with 2,4-D, but read the label carefully so you do not use it too soon. Cimarron (metsulfuron methyl + chlorsulfuron) should be applied no earlier than two months after planting bermudagrass as a post-emergent herbicide to control broadleaves and bahiagrass. Check with your North Carolina Cooperative Extension agent for additional information and current recommendations. If herbicides are not an option, then mowing at appropriate times can provide some control of weeds.

Hay, Haylage/Baleage, and Silage

For a general overview and detailed information on conservation practices for bermudagrass and other forage crops in North Carolina, see the NC State Extension publications AG-803, Hay Production and AG-812, Silage and Haylage Production. For detailed information on fertilization management, see AG-804, Forage Fertilization in North Carolina: Concepts and Guidelines.

For the best compromise between nutritive value (that is, crude protein and digestibility) and forage accumulation, harvest bermudagrass at four- to five-week intervals or when it is 12 to 15 inches tall, whichever comes first (Figure 6). Clip to a stubble height of 3 to 4 inches. A delay of two weeks or more in harvest time can result in loss of regrowth, lower crude protein concentration, and overall low nutritive value (Table 1).

| Clipping Frequency (weeks) | Forage Accumulation (tons/acre) | Crude Protein (%) | ||

|---|---|---|---|---|

| Wet Year | Dry Year | Wet Year | Dry Year | |

| 2 | 2.2 | 1.0 | 13.6 | 16.2 |

| 3 | 3.3 | 1.4 | 12.9 | 12.8 |

| 4 | 3.7 | 1.7 | 11.2 | 11.0 |

| 6 | 4.8 | 2.3 | 7.8 | 9.3 |

| 8 | 5.1 | 2.4 | 8.4 | 9.7 |

Adapted from Prine and Burton 1956.

Fall management of bermudagrass is important to maintain a vigorous stand and to prevent winter injury, particularly in the piedmont. At the start of winter, bermudagrass should have 3 to 4 inches of growth to insulate from winter damage. Do not graze or otherwise remove this growth before February 15.

Burning in winter to early spring has several benefits. Burning will encourage early spring growth by removing dead material from the previous year, which allows the soil to warm up quicker in the spring and reduces competition for sunlight as the new bermudagrass struggles to break dormancy. Spring burning also helps with weed management, particularly in sandbur-infested fields; burning will destroy the previous year’s sandbur seeds before they can germinate. Safety is the primary issue to consider when burning. If you do not have the necessary equipment or experience to safely burn a field, then err on the side of caution. Always check local burning laws and consult the North Carolina Forest Service to make sure no burning bans are in effect.

Grazing Management and Animal Performance

The balance between the number of grazing livestock and the land available for grazing (also known as the stocking rate) is a critical determinant of the animal and pasture responses. Pasture responses include forage accumulation, nutritive value, weed infestation, and persistence. Animal responses include individual animal responses (for example, weight gain and milk production) and also responses measured on an area basis (for example, weight gains per acre and milk production per acre).

When pastures are understocked, nutritive value of the forage may be lower due to infrequent defoliation and longer pasture-regrowth intervals that result in mature forage. With understocking, forage allowance (the amount of forage per animal at a point in time) will be greater; although individual animal responses may also be greater due to selective grazing by the livestock, the overall productivity per acreage will be lower. In contrast, overstocked pastures can result in reduced forage accumulation (and ultimately permanent damage of the pasture by killing the desirable forage species), increased weed pressure, and overall lower animal performance. For information on bermudagrass defoliation management, including when to start and stop grazing in rotationally stocked pastures, see AG-939, Pasture Grazing Heights for Rotational Stocking.

Well-managed bermudagrass can result in animal gains of about 1.5 pounds per day and stocking rates of over 1 animal unit per acre (1 animal unit = 1,100 pounds of live weight) during the growing season (about 100 days in North Carolina). Bermudagrass cultivars, however, respond differently to grazing management. For example, a four-year grazing study in the North Carolina piedmont indicated that although pasture productivity (about 2 tons per acre) was similar between Tifton 44 and Coastal continuously stocked with beef steers (about 610 pounds) to maintain a canopy height of at least 4 inches, Tifton 44 had slightly lower neutral detergent fiber, comparable crude protein concentration, and greater digestibility than Coastal. These pasture responses supported greater individual animal daily weight gains for Tifton 44 (1.4 pounds compared to 1.1 pounds for Coastal) but similar weight gains per acre (Burns and Fisher 2008). Data from a three-year experiment in Florida with Tifton 85 continuously stocked with crossbred yearling beef heifers (about 750 pounds) to maintain the canopy height at 8 inches tall reported an average stocking rate of 2.6 head per acre, individual animal average daily weight gain of 1.4 pounds per acre, and weight gains of 568 pounds per acre (Pedreira et al. 2016).

Keep in mind that grass grows at different rates depending on moisture, temperature, and other conditions. Because the peak of bermudagrass availability occurs in the middle of the summer (Figure 4), it can be challenging to impose proper grazing management throughout the year using a predefined stocking rate. As forage growth increases in the summer, and with a moderate stocking rate, a section of the pasture can be closed off, keeping animals concentrated in the remaining area to improve forage utilization and maintain proper grazing pressure in the grazed area. Excess growth can be stockpiled for use later in the fall or harvested for hay.

Stockpiling

Stockpiling, sometimes refer to as “standing hay,” is a forage management practice in which forage is grown in a reserved area for grazing later in the season. In recent years, more producers have become interested in stockpiling forage for late fall or winter grazing. Stockpiling eliminates the cost of mechanical harvesting, storage, and feeding that is incurred with conserved forages (such as hay, haylage, and silage). The nutritive value of stockpiled bermudagrass may not be as high as that of tall fescue but can still reach sufficient levels for dry cows in good body condition. In an on-farm demonstration in Johnston County (Figure 7), stockpiled bermudagrass fertilized with swine waste contained 11% crude protein and 57% total digestible nutrients (TDN) on October 7, but by October 28 the nutritive value declined to 10% crude protein and 55% TDN. Information about stockpiling is still scarce in North Carolina. The nutritive value of bermudagrass may decline more rapidly after frost, so grazing of stockpiled bermudagrass should begin in October.

To stockpile bermudagrass, clip or graze the field 6 to 7 weeks before the average first frost and apply 60 pounds of nitrogen per acre. Keep animals off the field and allow the pasture to grow until October. Use temporary electric fencing to provide livestock daily strips of forage and to help promote efficient use of the grazed forage (Figure 7). A network of electrified perimeter fencing can supply power to a reel of polywire or polytape supported on step-in posts to fence off temporary paddocks. The most common approach to initiate grazing is to start at the end of the field where the water is located and move the fence to the next area to be grazed every one to three days.

Weed Management

The primary defense against weed pressure is to establish and maintain a vigorous bermudagrass stand via proper fertilization and management of grazing or clipping. Early spring is the main time of year when many weeds (both broadleaf and grassy) will begin to outcompete bermudagrass. Proper weed identification is a critical component in weed control and management. Contact your local Extension agent to help you identify problem weeds or consult AG-764, Weed Identification in Pastures, Hayfields, and Sprayfields. For a compendium of herbicides, see Grass Pasture and Hay Field Herbicides. Note that herbicide labels are continuously updated, so seek advice from your Extension agent or consult the North Carolina Agricultural Chemicals Manual, which is revised annually.

Broadleaf weeds are readily controlled by the numerous herbicides on the market. Most of these products contain a blend of two or more chemicals and usually offer significant residual control. A single spring application of most broadleaf forage herbicides will provide sufficient control for the entire growing season. For heavy weed infestations or particularly troublesome weeds, a second application may be necessary later in the summer. Certain newer broadleaf herbicides offer very effective control but have high residual activity in the forage and can even persist in the waste of animals that graze the forage or eat treated hay. Hay from areas treated with these herbicides cannot be sold off the farm until 18 months after application. Always read and follow label directions.

Grassy weeds (for example, foxtail, vaseygrass, and crabgrass) are significantly more difficult to control than broadleaf weeds, and availability of effective herbicides is much more limited. Proper herbicide selection, as well as timing of application, is more critical when trying to control grassy weeds. It may take two to three years of spraying to effectively control heavy infestations of most grassy weeds. For production of pure bermudagrass hay, use of a pre-emergent herbicide is often advisable. Pre-emergent herbicides applied prior to spring growth or in sequential applications after hay harvest can be highly effective at reducing populations of annual weeds, particularly annual grasses.

Rezilon, a pre-emergent herbicide for use in established bermudagrass, provides control of many annual grasses and broadleaf weeds; it has no hay or grazing restrictions and has a longer-term residual effect. Weed species controlled by this herbicide include dogfennel, horseweed, redroot pigweed, crabgrass, crowfootgrass, goosegrass, ryegrass, and sedge. Consult the label for other controlled weed species. Multiple applications of Rezilon may be needed at different times of the year to control cool- and warm-season weeds. Because of its residual effect, plant back intervals for other crops are about 22 months. Overseeding of winter annuals should occur after at least 18 months.

Prowl H2O provides good pre-emergence control of summer annual grasses such as crabgrass and sandbur and some annual broadleaf weeds. It will not control emerged weeds. Prowl H2O is labeled only for established dormant bermudagrass. Apply Prowl H2O to established bermudagrass in winter dormancy in the late winter and early spring. Prowl H2O may also be applied as a sequential or split program when initial applications are made in the dormant season and subsequent applications are made in-season between cuttings. DO NOT apply more than a maximum cumulative total of 4.2 quarts of Prowl H2O per acre per year. There is no preharvest interval for grass forage, hay, or for livestock grazing after application.

Diseases

Several environmental and biotic factors can trigger bermudagrass diseases. Diseases are usually not a serious problem in adequately managed bermudagrass (that is, fertilized and harvested on a four- to five-week schedule); when present, however, diseases can negatively affect forage accumulation, nutritive value, and overall quality of forage crops. Bermudagrass leaf spot is caused by a fungus from the genus Helminthosporium (Bipolaris) and is informally called Helminthosporium leaf spot, Helminthosporium leaf blotch, or leaf blight. Areas affected by Helminthosporium appear to be frosted grass with reddish-brown to purplish-black spots on the foliage (Figure 8 and Figure 9). Leaf rust (also called Puccinia disease) is caused by Puccinia cynodontis, which forms pustules that, when disrupted, release an orange-red powdery mass of spores similar to rust. Both leaf spot and leaf rust typically appear in late summer when weather is warm, usually between 75°F and 90°F, with high relative humidity. There are no effective, economical, or legal fungicides to control those diseases in bermudagrass. Maintaining the appropriate potassium levels, burning the fields just before green-up, and harvesting or grazing on a regular schedule will help prevent the occurrence of these diseases.

Pests

Tolerance to pests and diseases varies among bermudagrass cultivars. Hence, cultivar selection and defoliation management, as well as insect and disease management, should be considered as part of an integrated pest management (IPM) approach. Pests of North Carolina bermudagrass fields include fall armyworms, green June beetles, fire ants, two-lined spittlebugs, sting nematodes, and bermudagrass stem maggots. Examine forages regularly to scout for insect infestations. Check frequently during the growing season, particularly during periods of drought. Monitor three to four locations in each 10-acre section. Symptoms of early insect infestation may be visible as chewed leaves. Symptoms also may be less obvious. Insects may appear on the foliage, hide in the crowns of plants, or feed on plant roots. Look for yellowing plants and spots where the grass may be dead or thinning.

Fall armyworm moths migrate north each year from the Caribbean islands, extreme southern Florida and Texas, and Central America. By early summer, they are laying eggs in pastures and hayfields in North Carolina. Damaging populations of caterpillars are usually reported in late July and early August when later generations of the pest are present, though outbreaks can occur as early as June. Hot, dry weather is favorable for fall armyworms. Fall armyworms must be treated when they are still small—no more than 1 inch long—so early detection is critical. When larvae are fully grown, they are less susceptible to insecticides. In addition, if the majority of the caterpillars are nearly grown, most of the feeding damage may already have been done.

The green June beetle is an increasing problem on North Carolina bermudagrass. The larvae of this beetle, commonly called grub worms, rarely feed on grass roots, but their extensive burrowing disrupts the roots’ contact with the soil. Once the soil around the roots is loosened, grazing cattle can easily uproot the plants. When green June beetle grubs are present, the pasture will appear thinned. The soil will be pulverized in some areas, and you may see 0.5-inch diameter tunnels made by the grubs. To scout for grubs, dig a 12-inch by 12-inch area 6 inches deep and count the grubs. A typical treatment threshold is four to five grubs per square foot. June beetle grubs can be effectively controlled with carbaryl during the winter if it is applied during warm periods when the grubs are active.

The impact of fire ants in pastures is hard to quantify because they affect different areas of the livestock operation. They injure both cattle and humans, and they also damage haying equipment, electrical equipment, and livestock feed. Controlling fire ants in livestock pastures can be difficult because of the extensive land area involved, the high cost of insecticides, and livestock safety considerations. For pastures, broadcast applications of baits are better than individual mound treatments because the visible mounds are only the tip of the iceberg; other colonies exist that have not yet built mounds. Mound treatments may be useful follow-ups a few weeks after the bait has been applied.

Two-lined spittlebugs can damage bermudagrass pastures. Nymphs and adults feed by sucking juices from the roots, stems, and leaves of bermudagrass. In heavy infestations, injured grasses tend to yellow and dry out. Damage occurs most frequently in dense, overgrown stands of bermudagrass. Two-lined spittlebugs produce two generations per year and overwinter as eggs in sheltered places, such as plant debris on soil, hollow stems, and behind leaf sheaths. Humid conditions are required for eggs to hatch and for development of young spittlebugs, which hide inside foamy masses of saliva-like material. No chemical control strategies are recommended. For control, burn the affected areas to destroy the spittlebugs and the accumulated thatch. If burning is not possible, mow the pastures and then rake to reduce the accumulated thatch.

Sting nematodes (Belonolaimus spp.) are occasional pests of bermudagrass where soil texture is coarse sand (about 85% sand by volume). If sting nematodes are present and the soil is sandy enough for them to be active and reproduce, the nematodes will devastate stands. They can be easily transferred in sprigs. There is no labeled chemical treatment. The only control options are to fortify bermudagrass with irrigation and high fertilization to encourage vigorous top growth and stimulate root growth. Root impairment usually happens in early spring. As soils warm and dry, this large-bodied nematode retreats deep into the soil. Bermudagrass with sting nematode injury is especially susceptible to other competitive stress.

Bermudagrass stem maggot is a newer insect pest affecting bermudagrass in the Southeast. The bermudagrass stem maggot fly lays eggs in the stem or sheath of a bermudagrass shoot, where the hatched larvae will feed. The stem and emerging leaves above the feeding site will wilt and eventually die. Infested bermudagrass fields have a bronze cast or wilted appearance that looks similar to frost damage. The top part of the plant is wilted, while the bottom part of the plant is healthy (Figure 10). Depending on the extent of infestation and the growth stage of the grass when the larvae hatch, yield losses can range from 10% to 60%. The most practical, cost-effective means of control is to cut the field for hay, or have livestock graze it, as soon as damage is observed.

Chemical control is also an option, but timing of the applications can be tricky. Two applications of a foliar insecticide (for example, pyrethroid) should be applied to a freshly harvested field 7 to 10 days apart to kill any emerging immature flies and break the life cycle. Spray options may or may not be cost effective for this pest. Research from a three-year on-farm trial in the sprayfields of North Carolina indicated that Tifton 85 was consistently much less affected by stem maggot than Coastal, Midland 99, Ozark, and Tifton 44 (Spearman et al. 2021) (Figure 11). Similar results comparing bermudagrass cultivars have been reported in Georgia (Baxter et al. 2015).

Nitrates

Nitrate poisoning in livestock is caused by the consumption of feed or water containing high levels of nitrate nitrogen. Normally, forages do not contain levels of nitrates high enough to be toxic. But when circumstances occur that slow the rate of plant growth—such as periods of low soil moisture, low temperature, low humidity, cloudy weather, or drought—increased nitrate levels in the plants can poison or kill livestock. Any time the nitrogen supply in the soil exceeds the nitrogen needs of the plant, nitrate can increase to toxic levels in forages.

Significant instances of animal deaths most commonly occur when a producer places hungry animals that are not adapted to nitrate on high-nitrate forages. Note that nitrates degrade little with drying, so you should analyze hay not only for nutrient value, but also for nitrate levels.

Symptoms of nitrate poisoning include labored breathing, muscle tremors, frothing at the mouth, frequent urination, diarrhea, and a staggering gait, after which the animal falls down, gasps for breath, and dies quickly. The membranes of the eyes and mouth of affected animals are bluish, indicating a lack of oxygen. If a venous puncture is made, the blood will be reddish-brown but will turn a brighter red when exposed to air.

On a three-year on-farm trial in North Carolina, five cultivars of bermudagrass were grown in sprayfields, with tissue nitrate ion concentration values ranging from 0.34% to 1.6% (Spearman et al. 2021). The generally considered safe thresholds for all kinds of livestock (if forage is the sole source of feed) is ≤0.5% nitrate ion; however, this threshold can range between 0.25% and 0.5% (Hancock 2013; Gadberry and Jennings 2016; Poore et al. 2000). Forages with nitrate ion concentrations over 0.5% can be fed as a proportion of the ration, and there are several categories proposed in the literature (Hancock 2013; Poore et al. 2000).

Most state labs and commercial labs will analyze forages for nitrate. The North Carolina Department of Agriculture & Consumer Services Food and Drug Protection–Feed Program will, upon request, analyze a forage for nitrate, or add nitrate testing to standard forage quality analysis at no extra charge. The lab will notify producers immediately if high nitrate levels are discovered. Commercial labs usually add a small surcharge when nitrate analysis is requested. Table 2 lists feeding precautions for beef livestock based on nitrate ion percentage reported from the lab.

| Level in Forage (Dry Matter Basis) | Feeding Precautions | |

|---|---|---|

| Nitrate ion (%) | Unadapted Animals | Adapted Animals |

| 0.0–0.25 | Safe: Generally considered safe for all animals. | Safe |

| 0.26–0.50 | Slight risk: Should not make up more than 50% of total intake for pregnant animals. | Safe |

| 0.51–1.00 | Moderate risk: Do not feed to pregnant animals. Limit to less than 50% total intake for all other animals. | Slight risk |

| 1.01–1.50 | High risk: Exercise extreme caution when feeding. Limit to 33% of the ration. | Moderate risk |

| 1.51–2.00 | Severe risk: Do not feed to any animals via free choice. If using in a mixed ration, limit to 25% of the ration. | High risk |

| 2.01–2.50 | Extreme risk: Do not feed. | Severe risk |

| 2.51 and up | Extreme risk: Do not feed. | Extreme risk |

Adapted from Poore et al. 2000.

Acknowledgments

This publication is a revision of an earlier version. The authors would like to thank Tiffanee Boone, Tyrone Fisher, Amanda Hatcher, Michelle Shooter, and Lynn Stillwell for their original contributions.

References

Aiken, G. E. 2014. "Cool-Season Annual Grasses Interseeded into a Bermudagrass with Improved Cold Tolerance for Grazing in the Upper South." Forage and Grazinglands 12 (1): 1–6. ↲

Anderson, J. A., and Y. Q. Wu. 2011. "Freeze Tolerance of Forage Bermudagrasses." Grass and Forage Science 66 (3): 449–452. ↲

Baxter, L. L., D. W. Hancock, W. G. Hudson, S. L. Dillard, W. F. Anderson, and B. M. Schwartz. 2015. "Response of Selected Bermudagrass Cultivars to Bermudagrass Stem Maggot Damage." Crop Science 55 (6): 2682–2689. ↲

Burns, J. C., and D. S. Fisher. 2008. "‘Coastal’ and ‘Tifton 44’ Bermudagrass Availability on Animal and Pasture Productivity." Agronomy Journal 100 (5): 1280–1288. ↲

Burns, J. C., M. G. Wagger, and D. S. Fisher. 2009. "Animal and Pasture Productivity of ‘Coastal’ and ‘Tifton 44’ Bermudagrass at Three Nitrogen Rates and Associated Soil Nitrogen Status." Agronomy Journal 101 (1): 32–40. ↲

Burton, G. W., and A. W. Johnson. 1987. "Coastal Bermudagrass Rotations for Control of Root-knot Nematodes." Journal of Nematology 19 (1): 138–140. ↲

Gadberry, S., and J. Jennings. 2016. Nitrate Poisoning in Cattle. FSA3024. University of Arkansas Division of Agriculture, Research & Extension. ↲

Hancock, D. 2013. Nitrate Toxicity. Circular 915. UGA Extension. ↲

Pedreira, C. G. S., V. J. Silva, Y. C. Newman, and L. E. Sollenberger. 2016. "Yearling Cattle Performance on Continuously Stocked ‘Tifton 85’ and ‘Florakirk’ Bermudagrass Pastures." Crop Science 56 (6): 3354–3360. ↲

Poore, M., J. Green, G. Rogers, K. Spivey, and K. Dugan. 2000. Nitrate Management in Beef Cattle. North Carolina Cooperative Extension Service. ↲

Prine, G. M., and G. W. Burton. 1956. "The Effect of Nitrogen Rate and Clipping Frequency upon the Yield, Protein Content and Certain Morphological Characteristics of Coastal Bermudagrass (Cynodon dactylon, (L) Pers.)." Agronomy Journal 48 (7): 296–301. ↲

Rios, E. F., Y. Lopez, P. Munoz, J. C. B. Dubeux, J. M. B. Vendramini, M. Wallau, et al. 2023. "‘Newell’ Bermudagrass: A Public Release from the USDA Cynodon Collection." Journal of Plant Registrations 17 (3): 605–615. ↲

Spearman, R. L., M. S. Castillo, and S. Sosinski. 2021. "Evaluation of Five Bermudagrass Cultivars Fertigated with Swine Lagoon Effluent." Agronomy Journal 113 (3): 2567–2577. ↲

Taliaferro, C. M., F. M. Rouquette, and P. Mislevy. 2016. "Bermudagrass and Stargrass." Warm-Season (C4) Grasses 45: 417–475. ↲

Additional Resources

Castillo, M., D. Crouse, D. Osmond, D. Hardy, J. Burns, and J. Green. 2015. Forage Fertilization in North Carolina: Concepts and Guidelines. AG-804. Raleigh, NC: NC State Extension.

Castillo, M., B. Spearman, D. Wells, and K. Woods. 2020. Planting Guide for Forage Crops in North Carolina. AG-266. Raleigh, NC: NC State Extension.

Castillo, M. 2022. Pasture Grazing Heights for Rotational Stocking. AG-939. Raleigh, NC: NC State Extension.

Castillo, M. 2024. Hay Production. AG-803. Raleigh, NC: NC State Extension.

Castillo, M. 2024. Silage and Haylage Production. AG-812. Raleigh, NC: NC State Extension.

Spearman, B., M. Shooter, T. Conrad, D. Wells, and R. Wood. 2013. Weed Identification in Pastures, Hayfields, and Sprayfields. AG-764. Raleigh, NC: NC State Extension.

Yelverton, F., and T. Murphy. 2017. Grass Pasture and Hay Field Herbicides.

Publication date: Oct. 15, 2024

AG-493

Recommendations for the use of agricultural chemicals are included in this publication as a convenience to the reader. The use of brand names and any mention or listing of commercial products or services in this publication does not imply endorsement by NC State University or N.C. A&T State University nor discrimination against similar products or services not mentioned. Individuals who use agricultural chemicals are responsible for ensuring that the intended use complies with current regulations and conforms to the product label. Be sure to obtain current information about usage regulations and examine a current product label before applying any chemical. For assistance, contact your local N.C. Cooperative Extension county center.

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.