Introduction

In periods of fresh forage shortage (for example, caused by limited pasture growth or inadequate pasture conditions), forages can be conserved to feed to livestock, or as a supplement (for example, when supplementing with a legume). Conserved forages can take the form of hay, haylage or baleage, and silage. While several techniques have been proven as efficient ways to store forages, it is important to keep in mind that, at best, conserved forages can rarely match the nutritive value of fresh forage, and some losses of highly digestible nutrients (sugar, protein, and fat) are unavoidable. The goal in forage conservation should focus on minimizing losses, which occur immediately after cutting.

The process of selecting a conservation technique should take into account the suitability of the forage for a given technique, storage capability, weather conditions, and the intended use of the conserved forage. The selected conservation technique should maximize nutrient conservation efficiency and minimize production costs.

Hay Production

Hay is defined as forage conserved under aerobic dry or limited moisture conditions. Fresh forage is typically between about 75% and 85% moisture concentration (Collins and Coblentz, 2013). Thus, the goal in hay production is to remove moisture as quickly as possible to achieve a target moisture concentration equal to or less than 18% (or a target dry matter concentration greater than 82%). The process of reducing moisture is called curing and is normally accomplished with energy provided by the sun (field curing) or by artificial barn drying using heated or unheated air. Moisture concentration less than 20% prevents plant respiration and allows for an almost complete conservation of plant nutrients for extended periods (years). Factors that influence the process of moisture loss for hay production can be classified into three types: (1) forage-related, (2) weather-related, and (3) management (Rotz, 1995; Collins and Owens, 2003):

-

Forage-related Factors

Stem Thickness and Waxy Cuticle

Physical characteristics of plants can affect the drying process. As stem thickness increases, the drying process slows because of increased radial distance from the stem core to the epidermis that water must travel to move out of the plant. It is more difficult to dry thick-stemmed, erect plants—such as corn and sorghum-type plants—as fast as plants with thinner stems, such us tall fescue, orchardgrass, or bermudagrass (Brink et al. 2014). In addition, the epidermis of leaves covered with a waxy, impermeable cuticle slows down the process of water loss.

Forage Species

Grasses tend to dry faster than legumes. Among legumes, alfalfa and birdsfoot trefoil tend to dry faster than red clover; among grasses, tall fescue dries faster than ryegrass, and timothy (Tetlow and Fenlon, 1978), and bermudagrass. The differences in drying rates among forage species are mostly a consequence of a high surface area to dry-weight ratio. In addition, forages with higher leaf to stem ratios dry faster because leaves dry faster than stems (Rotz, 1995). Perennial crops are usually the best option for hay production to minimize the impact of establishment cost. Table 1 indicates expected yield by region of the main crops used for hay production in North Carolina.

Table 1. Dry Matter Yield by Region of the Most Common Forage Crops Used for Hay Production in North Carolina Type Forage Region Dry Matter Yield (lb/ac/yr) Cool-season forages Alfalfa Coastal Plain 7600 Piedmont 8000 Mountains 7600 Ryegrass-Annual

Coastal Plain 7000 Piedmont 6600 Mountains 6000 Ryegrass, Perennial

Coastal Plain NA1 Piedmont 6000 Mountains 6600 Small grain-Oat

Coastal Plain 4000 Piedmont 3500 Mountains 3000 Small grain-Rye

Coastal Plain 4900 Piedmont 4500 Mountains 4000 Small grain-Triticale

Coastal Plain 5200 Piedmont 4500 Mountains 4200 Small grain-Wheat

Coastal Plain 4400 Piedmont 4000 Mountains 3600 Timothy

Coastal Plain NA [1] Piedmont 6000 Mountains 5500 Tall fescue

Coastal Plain 6350 Piedmont 6350 Mountains 5850 Orchardgrass

Coastal Plain NA Piedmont 6500 Mountains 7000 Warm-season forages

Bermudagrass (common, hybrid, improved seed)

Coastal Plain 7683 Piedmont 7475 Mountains 5975 Big bluestem

Coastal Plain 7000 Piedmont 7000 Mountains 6000 Gamagrass

Coastal Plain 6350 Piedmont 6350 Mountains 5850 Switchgrass

Coastal Plain 8500 Piedmont 8000 Mountains 7500 [1] NA: data not available ↲

-

Weather-related Factors

The most unpredictable variable to deal with when making hay is the weather. In reality, very little can be done to the plant or swath to improve drying rates if the environmental conditions are not conducive to moisture loss. Weather factors are highly correlated among each other, and it is therefore difficult to isolate the effects of each factor. Favorable conditions for hay production include high temperature, high solar radiation, and moderate wind speed (up to 12 miles per hour), in conjunction with low air relative humidity and low soil moisture. Although weather conditions can change rapidly, checking the weather forecast may aid in determining days of continuous dry weather and limited rainfall to avoid losses due to nutrient washout.

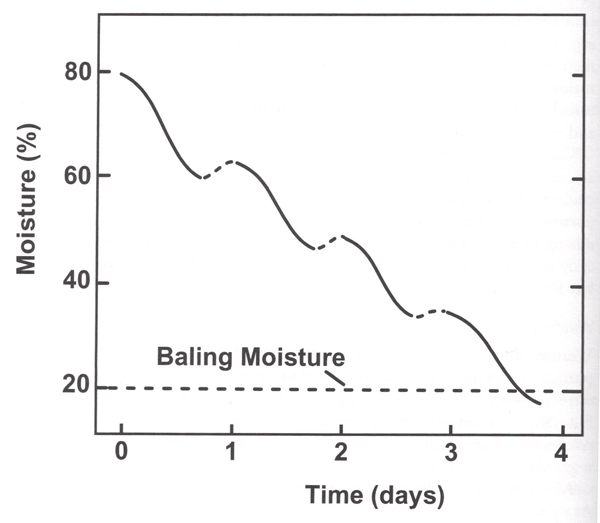

The drying rate is faster at the beginning of the drying process, but it slows down and reaches zero when moisture equilibrium with the environment is reached. If humidity in the environment is greater than 70%, moisture loss will cease even if temperatures are high. In most regions, hay moisture follows a diurnal pattern in which drying occurs during the day while the lost moisture is partially replaced from the air during the night as humidity levels rise or dew forms (Figure 1).

-

Management Factors

Hay will usually require three to five days or more of field curing to reduce moisture to less than 20%. It is especially important to dry hay to less than 40% moisture as soon as possible to prevent nutrient loss due to plant respiration and microbial degradation. The text that follows addresses several management decisions during each step of the haymaking process. These decisions can help speed drying and preserve the nutritive value and overall quality of the forage (Rotz, 1995; Rotz and Shinners, 2007).

Mowing

High quality forage hay production begins when the crop is mown. Forage crops should be mown at the right maturity to achieve adequate yield and nutritive value. While greater amounts of forage accumulate during longer regrowth periods, the nutritive value of the forage diminishes over this time. In addition, the nutritive value in most forages declines rapidly as the crop enters the reproductive stage. As plants mature, there is greater accumulation of cell wall components (lignin, cellulose, and hemicellulose) compared to cell contents (protein and carbohydrates), and there is mobilization of nutrients from the vegetative tissue (leaf and stems) to the reproductive tissue, or seedhead. Table 2 indicates two measurements of nutritive value (digestibility and crude protein) and the percentage of dry matter concentration at each physiological stage. Generally, this compromise is best reached with legumes, such as alfalfa and clovers, by harvesting at an early bloom stage. With grasses (for example, fescue and orchardgrass), this compromise is best reached when they are just beginning to produce their seedheads.

Table 2. Nutritive Value and Dry Matter Concentration Estimates at Different Physiological Stages Crop Physiological Stage Digestibility (%) Crude Protein (%) Dry Matter Concentration (%) Alfalfa Vegetative (early spring) 75–80 25–30 15–20 Early bud (top 1/2 of canopy) 70–75 20–25 20–25 Early bud (bottom 1/2 of canopy) 60–65 16–20 25–30 10% bloom (top 1/2 of canopy) 68–72 18–22 25–30 10% bloom (bottom 1/2 of canopy) 55–60 14–18 30–35 Bermudagrass [1] Vegetative (<4" tall & 14 days of age) 56–62 15–18 15–20 Vegetative (6ʺ–10ʺ & 14–21 days of age) 52–58 12–16 20–25 Vegetative (10ʺ–15ʺ & 21–28 days of age) 50–54 11–14 25–30 Mature (4–6 weeks) 46–50 8–10 30–35 Mature (8–12 weeks) 40–45 5–7 30–35 Caucasian bluestem Vegetative (6ʺ–8") 76+ 15–17 18–22 Vegetative (8ʺ–12") 70–74 12–14 23–25 Heading 65–69 10–12 29–33 Fescue/Orchardgrass/Ryegrass/Prairiegrass Vegetative (10–21 days of age) 70+ 17–22 15–20 Vegetative (21–35 days of age) 60–70 13–18 20–25 Vegetative (fall stockpiled) 65–70 12–15 20–25 Boot 60–65 13–15 20–25 Heading 55–60 10–12 20–25 Flowering 50–55 8–10 25–30 Seeds Forming 45–50 6–8 25–30 Gamagrass Vegetative (12ʺ–18") 72+ 16–18 18–22 Vegetative (25ʺ–35") 65–70 12–15 25–28 Heading 52–56 8–12 30–35 Small grains [2] Vegetative (4ʺ–8" tall) 75+ 18–25 10–15 Vegetative regrowth (4ʺ–8" tall) 70–75 16–22 10–15 Stem elongation (8ʺ–12") 68–72 14–20 12–18 Boot stage 63–68 12–18 20–26 Switchgrass Vegetative (12ʺ–20ʺ) 74+ 15–17 18–22 Vegetative (25ʺ–35ʺ) 62–68 10–13 24–27 Boot stage 56–60 6–8 28–32 Heading 43–49 3–5 34–40 Flowering 39–42 3–4 42–45 Seed set 32–37 3–4 45–48 [1] Seeded and hybrids may vary slightly within stages. ↲

[2] Oats, rye, triticale, and wheat may reach growth stages at different times. ↲

Several types of mowers are available for cutting hay, including sickle bar, disc, rotary drum, and flail (Figure 2, Figure 3, Figure 4, and Figure 5). The type of mower used has little effect on drying, loss of dry matter, and the resulting forage quality. Mowing height and frequency have the greatest effect on persistence and nutritive value of the forage.

Curing Process

Conditioning: An optional step in the haymaking process, conditioning helps accelerate the drying rate. Conditioner equipment (Figure 6) bends and crushes the forage to create openings that promote moisture loss, especially from stems. This process can reduce hay-curing time by one to two days, and it is mostly effective on stemmy forages (that is, forage with a low leaf to stem ratio). Most current mowers can also condition the forage. Nevertheless, excessive conditioning can be counterproductive and result in high harvest losses due to leaf shattering, especially with alfalfa and other legumes.

Swath Structure: As the thickness and density of the swath increases, the drying process slows. This correlation exists because a high moisture microclimate that restricts moisture loss forms inside thick swaths even when weather conditions are optimal. Once the tops of swaths start drying out, they can be tedded to promote faster, more uniform drying. Some mowers contain adjustable baffles to set the width of swath or allow forage to be windrowed at cutting.

Tedding: Hay tedders (Figure 7) disperse forage across the field so that more solar radiation can reach it and it can dry more quickly (about half a day faster) and uniformly. Tedding is most beneficial for material containing greater than 40% moisture. A second tedding may also be used to help in the drying process; nevertheless, be conscious that too much tedding can shatter leaves of forages, lowering the quality of the hay.

Raking: Once the hay has been tedded and has almost reached the target moisture, it is time to rake. Raking turns the forage one more time and forms it into a windrow ready to be baled (Figure 8).

Bailing

Dry forage can be baled in small and large rectangular bales and large round bales. Small rectangular bales usually measure about 1.5 feet wide and high by 3–4 feet deep and weigh 40–60 pounds. Large rectangular bales measure 3–4 feet wide and high by 6–8 feet deep and weigh more than 800 pounds. Large round bales measure 4–6 feet in diameter by 4–5 feet wide and weigh 1,000–2,000 pounds.

Storage

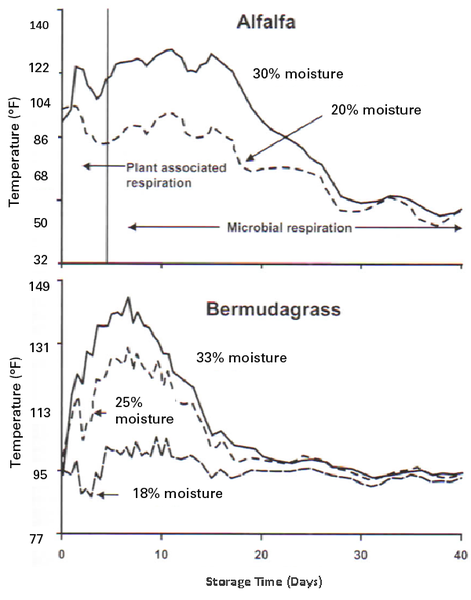

Dry matter losses during storage are usually 5% when bailing moisture is around 15% and hay is covered, which is highly recommended. It has been estimated that dry matter weight loss can average about 1% for each moisture percentage above 10% at the time of storage. Higher moisture concentrations (greater than 20%) at harvest can also cause heat damage due to microbial degradation, which consumes the most nutritive fractions of the forage, leaving behind the least digestible material and potentially generating mycotoxins. Also, there is the risk of spontaneous combustion and ultimately barn fires.

Figure 9 explains the effect of moisture at bailing on storage temperature over time. When bailing is performed under high moisture conditions (that is, greater than 20% moisture), extra measures need to be taken to reduce moisture. One option is to treat with artificially heated or unheated air. Other alternatives include the use of organic acids (propionic or acetic acids) that provide protection only up to six months; buffered acids (ammonium propionate) that are less corrosive to equipment; and ammonium sources (anhydrous ammonia or urea) that require a plastic seal to retain the ammonia in the forage. Urea is especially attractive because it is not as hazardous as anhydrous ammonia.

Factors to Consider When Evaluating Hay

Laboratory testing of hay provides the most accurate estimate of hay quality. Two of the most commonly used methods to assess the quality of forages are the indices Relative Feed Value (RFV) and Relative Forage Quality (RFQ). Calculation and interpretation of both indices are discussed in Extension Publication AG-792, Forage Quality: Concepts and Practices (Romero et al., 2014). Unfortunately, index quality values of hay are not readily available in the hay market. Consequently, other attributes such as proportion of leaves, texture, color, and aroma could also be used to try to rank the quality of hays.

Leaves contain two to three times as much nutrients as stems. Consequently, it can be expected that the leafier the hay, the higher the quality. Texture pertains to stem size (length and diameter) and softness (flexibility). Long, thick stems that are hard and rigid are undesirable for animals; small, flexible stems are desirable. A bright, dark-green color in hay usually indicates high vitamin and protein content. Browning of hay usually indicates a loss of nutrients. Heat-damaged hay turns dark brown, whereas unbleached hay is a lighter shade of brown. A moldy odor indicates that the hay was baled too wet. When the odor is present, check for evidence of mold, which appears as a grayish-white, flaky substance or “dust” usually located in tightly packed sections of the bale.

Summary

Hay is an effective strategy to provide feed for livestock during periods of forage supply shortage or as a supplement, especially when feeding legumes. Successful hay production is more likely in regions and under environmental conditions that are conducive to rapid moisture reduction in the plant material to at least 15%, but no more than 20% before storage. Perennial forages such as alfalfa, tall fescue, orchardgrass, and bermudagrass are very well suited for hay production because rapid moisture loss can be achieved to minimize nutrient and dry matter losses.

Literature Cited

Brink, G. M., F. Digman, and R. E. Muck. 2014. "Field Drying-rate Differences among Three Cool-Season Grasses." Forage and Grazinglands. ↲

Collins, M., and W. K. Coblentz. 2013. "Post-Harvest Physiology." In Forages: The Science of Grassland Agriculture, edited by R. F. Barnes et al., 6th ed., vol. 2, 583–599. ↲

Collins, M., and V. N. Owens. 2003. "Preservation of Forage as Hay and Silage." In Forages: An Introduction to Grassland Agriculture, edited by R. F. Barnes et al., 6th ed., vol. 1, 443–471. ↲

Romero, J. J., M. S. Castillo, J. C. Burns, P. Moriel, and S. Davidson. 2014. "Forage Quality: Concepts and Practices." AG-792. College of Agriculture and Life Sciences, North Carolina State University, North Carolina Cooperative Extension Service. ↲

Rotz, C. A. 1995. "Field Curing of Forages." In Post-harvest Physiology and Preservation of Forages, edited by K. J. Moore and M. A. Peterson, 39–66. Madison, WI: Crop Science Society of America. ↲

Rotz, C. A., and K. J. Shinners. 2007. "Hay Harvest and Storage." In Forages: The Science of Grassland Agriculture, edited by R. F. Barnes, C. J. Nelson, K. J. Moore, and M. Collins, 601–616. Ames, IA: Blackwell Publishing. ↲

Tetlow, R. M., and J. S. Fenlon. 1978. "Pre-harvest Desiccation of Crops for Conservation. 1. Effect of Steam and Formic Acid on the Moisture Concentration of Lucerne, Ryegrass, and Tall Fescue Before and After Cutting." Journal of British Grassland Society 33:213–222. ↲

Acknowledgment

This publication is a revision of an earlier version. The authors would like to thank J.J. Romero, J.C. Burns, Paul Mueller, and Jim Green for their earlier contributions.

Publication date: April 12, 2024

AG-803

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.