Introduction

Sanitation of previously used flue-cured tobacco float trays prior to seeding each year is an important step in managing Pythium spp. and Rhizoctonia solani in the greenhouse. In the past, growers utilized methyl bromide to eliminate pathogens from float trays, but it is no longer available. Existing options to completely eliminate pathogens are to purchase new trays each season, which is cost prohibitive, or steam sanitation.There are a number of agricultural related businesses and individuals that steam trays for growers, but the cost per acre can range signficantly. While steaming trays has been available for many years, the simplicity and cost effectiveness of chemical fumigation limited the widespread adoption of this method at the farm. Although commercially available steam sanitation systems can be purchased (Figure 1), the information and specifications provided can be used by growers to build their own tobacco float tray steam sanitation system.

Steam Sanitation

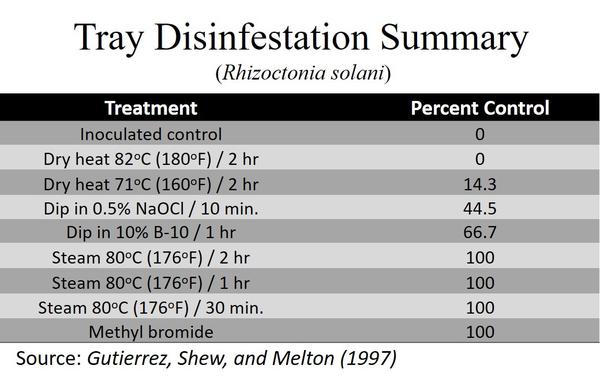

Previous research has shown that trays should be steamed at 176°F (80°C) for 30 minutes (Table 1). However, recent work demonstrated that it is possible to steam trays at 158°F (70°C) for 2 hours and maintain 100% control. The benefit of a reduced temperature threshold is the reduced performance specifications required of the steam equipment used for this process. Although the reduced temperature and extended time were shown to work in a single study, the higher temperature recommendation has proven to be effective over a number of years and actual on-farm results. It should also be emphasized that steam must be used, not dry heat. Simply placing the trays in a bulk barn, or other structure, and advancing the heat to the desired temperature at the corresponding time required will not be very effective. Steam is more effective at penetrating cracks in the tray walls to ensure contact with all potential pathogens. Care should be taken to prevent overheating the trays because Styrofoam trays will shrink if exposed to elevated temperatures (> 200°F), and the amount of damage will increase withe exposure time. It should be noted that steam also will not eliminate black root rot (Thielaviopsis basicola) or tobacco mosaic virus organisms. Proper protocol should be followed when handling the trays and placing them in storage to avoid re-contamination of the trays.

System Specifications

Most growers can build or purchase a structure to store trays for a steam sanitation system (Figure 2). If trays are going to be steam sanitized prior to seeding during winter months, then the tray storage structure should be insulated due to the lower ambient temperatures. At a minimum, 1 in. of foam insulation is recommended to minimize heat loss and to decrease the time required to complete the process. Growers who are steaming trays after transplanting during the spring may not necessarily need as much insulation added because the ambient temperatures will be higher. However, regardless of the time of the year the trays are sanitized, the process time could be extended without any insulation added to the storage structure. Any tray storage structure should also incorporate a manifold to distribute the steam uniformly around the trays (Figure 3). Ideally, the manifold is positioned beneath the trays in a lower plenum that is approximately 2 in. to 4 in. high. This distance is measured from the floor to the bottom of the trays. A general guideline for the steam distribution system is to include ¼ in. or larger diameter holes spaced 12 in. to 18 in. apart on the manifold lines for the steam to exit, to minimize flow restrictions, and to improve distribution around all the trays. The steam generator outlet hose should have an inner diameter of 1 in. or larger to minimize flow restrictions and have a temperature and pressure rating greater than the steam outlet conditions. Any structure purchased or constructed for steaming trays should have at least one thermometer incorporated on the structure that can be easily seen to accurately monitor the process temperature (Figure 4). Additionally, a thermometer and pressure gauge are reommended in the steam supply line to monitor the steam entering the tray storage structure. It should be noted that due to the multiple variables involved, the time to reach a uniform temperature will vary with steaming systems used. Another important reason to monitor the process temperature is to avoid exposing the Styrofoam trays to temperatures greater than 200°F for any amount of time during the process.

Although many growers can build or purchase a stray storage structure, most will not have the steam generating equpment needed for this application. The steam generator thermal energy requirement (Btu/hr) is based on factors that include the steam generator water supply flowrate, quantity of trays (size of structure), structure design, ambient temperatures and other factors. There are commercially available steam units, but if the structure volume (tray capacity) and steam capacity are not properly matched, the system throughput (trays per hour) can be significantly reduced. This will result in an increase in the time required and cost to sanitize a given acreage. We constructed a steam generator from a Northern Tool add-on heating unit (Northern Tool Item #157495) designed to convert an existing cold water pressure washer into a hot water/steam pressure washer (Figure 5). Additional diagnostic and safety components were added to improve adaptation for this application. The add-on unit uses a fuel oil burner and is rated at a maximum burner output capacity of approximately 353,000 Btu/hr. A flowmeter was incorporated to reduce the inlet water supply flow to approximately 0.5 gallons per minute (gpm) to maximize the quantity of saturated steam generated for the rated burner capacity. Matching the water supply with the burner capacity also assist with maintaining a constant outlet steam temperature of approximately 220oF. The total cost for the steam generator and additional components is approximately $2,100.

On-farm performance information was collected from multiple locations over several seasons to evaluate the steam generator throughput capacity (trays per hour). At three locations the growers used their existing tray storage container and the modified Nothern Tool steam generator was used to assist with the sanitation process. The float trays were steamed prior to reseeding their greenhouses at these locations (February). The remaining locations used a modified 15 ft. insulated shipping container to store trays and the Northern Tool steam generator after they finished transplanting (May-June). As a result, trays were steam sanitized under various ambient temperatures across the locations.The number of trays loaded per cycle across all locations ranged from 400 to approximately 2,000 trays. The turnaround time ranged from 0.75 hours to 2.80 hours.The process turnaround time per cycle includes the time required to load and unload the trays and the time required to raise the container temperature to 176°F (80oC) and maintain that temperature for 30 minutes. The on-farm performance results demonstrated that the modified Northern Tool add-on unit steam generator can work well for any acreage tobacco operation. If you need additional details on how to modify the Northern Tool unit as a steam generator or other steam sanitation system components contact your N.C. Cooperative Extension center.

Safety Precautions

Steam can cause serious injuries, and correct safety precautions should be used with any equipment that produces steam. The main danger of working with steam is burns or scalding to the skin. The tray sanitization application will result in exposure to steam temperatures equal to and exceeding 212°F (80oC). Wear appropriate personal protective equipment (PPE) such as gloves, eye protection, long pants, and boots. Remember the steam distribution system and related components will remain at elevated temperatures after the process has stopped during loading and unloading. Steam will reduce visibility, which could result in other accidents. Condensation of steam will cause floors to become slippery, which will increase the risk of slipping or falling. Steam can also get into electronic devices and outlets resulting in an electric shock. The system should be operated away from outlets, and be sure to cover any electrical equipment in close proximity during the process and ensure it is dry before using. Also, do not bypass or disconnect factory installed safety features incorporated on any commercial steam or hot-water equipment purchased or modified for this application.

Useful Resources

Tobacco Growers Information Portal

For more information regarding equipment specifications and costs associated with building your own steam sanitation system Contact your local N.C. Cooperative Extension agent.

References

Gutierrez, W. A., H.D. Shew, and T.A. Melton. 1997. Sources of inoculum and management for Rhizoctonia solani damping-off on tobacco transplants under greenhouse conditions. Plant Dis. 81:604-606.

Thiessen, L.D., Ellington, G.H., Macialek, J.A., Johnson, C.S., Reed, D.T. 2019. Sanitation of float trays for the Management of pythium species in tobacco float systems. Plant Health Progress. 21:21-25.

Thiessen, L.D. 2019. “Managing Diseases”. 2019 Flue-Cured Tobacco Guide. NC State Extension, pp. 118-143.

Ellington, G.H. 2023 “Curing and Mechanization”. 2023 Flue-Cured Tobacco Guide. NC State Extension, pp. 175-201.

Publication date: April 10, 2019

The use of brand names in this publication does not imply endorsement by NC State University or N.C. A&T State University of the products or services named nor discrimination against similar products or services not mentioned.

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.