Continuous supply of biomass directly from the field is limited by the seasonality of production of warm-season bioenergy grasses in the US transition zone. The information in this factsheet summarizes multiple field trials conducted in North Carolina (Bekewe et al. 2019, 2020; Rivera-Chacon et al. 2022) that evaluated agronomic management and alternatives that extend the switchgrass feedstock supply beyond the traditional harvest times.

Introduction

Finite fossil fuel reserves, government mandates for the use of renewable energy, and controversies about land dedicated to animals and agriculture versus bioenergy production have turned attention to the use of grasses as potential bioenergy feedstocks. Switchgrass (Panicum virgatum L.) is a warm season perennial grass that is native to the North American prairies with potential as a dual-purpose crop used both as forage and a bioenergy crop. Multiple harvest events per year successfully enable this dual use of switchgrass for forage and bioenergy (Bekewe et al. 2020; Burns et al. 1984; Mosali et al. 2013; Richner et al. 2014; Sanderson et al. 1999). See Figure 1.

When switchgrass was used as forage and continuously stocked with cattle to maintain a canopy height between 30 to 40 cm during the summer (June to September) in North Carolina, the animal responses were 1.6 lb per day for individual animal weight gain and 332 lb of weight gain per acre. The stocking rate was 2.3 steers per acre (Burns and Fisher 2012). The nutritive value of the forage was 67% in vitro dry matter digestibility and 10.3% of crude protein. As a bioenergy crop, dry matter yields in North Carolina in the southeast US region ranged between 5 to 7 ton per acre (Fike et al. 2006).

Switchgrass as a Bioenergy Feedstock

Attributes that make switchgrass desirable for bioenergy feedstock include high biomass production, greater biomass yield per unit of N uptake than cool-season grasses, adaptation to marginal lands that are less suitable for row crop production, and drought tolerance. In addition, in our experience in North Carolina after hurricane Matthew in 2016, switchgrass persisted after being submerged in water for several days. Thus, we consider switchgrass a more flood-tolerant grass species than tall fescue and bermudagrass.

A major logistical issue with the use of biomass is storage, especially when there is seasonal availability (Rentizelas et al. 2009). The southeast US transition zone is characterized by the intersection of the cool-humid north and the warm-humid south. We evaluated the effects of in-season harvest management and harvest timing at the end of the growing season. We assessed if delayed harvest after freeze events can be an alternative to extending the window of switchgrass biomass directly from the field to the bioprocessing plants in the region.

Effect of Harvest Management on Harvestable Biomass, Dry Matter Concentration, and Removal of Nutrients and Ash

Harvestable Biomass Yield

There are multiple strategies available for defoliating (through clipping or grazing) switchgrass, while also ensuring its persistence and minimizing weed infestation. Sustained biomass yields with limited weed infestation when clipping is the defoliation method that can be obtained when light interception of the switchgrass canopy is at least 70% at the time of harvest (Bekewe et al. 2019). For maximizing total biomass for bioenergy purposes, the most common strategies for defoliation include allowing switchgrass to grow for the full season and then cutting it one time (1X) at the end-of-season by October before a freeze event in North Carolina or harvesting twice per season (2X). With 2X management, the first harvest is done by mid-season in June or July and the regrowth is harvested by October.

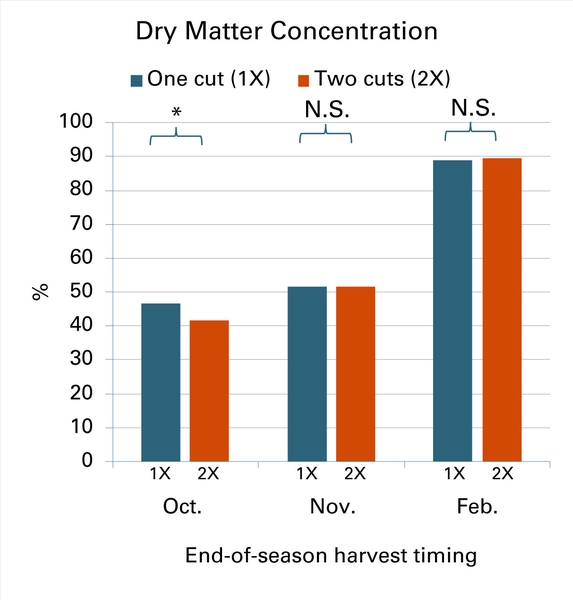

Total seasonal biomass yield of 1X and 2X defoliation management can result in similar or about 30% greater biomass yield for 2X. Reports in the literature vary. For ‘BoMaster’ switchgrass, biomass yields were similar at about 6.5 tons/acre for both 1X and 2X (Figure 2). However, delaying the end-of-season from October (before a freeze event) to November and February had different effects on biomass yield for 1X versus 2X.

Delaying the end-of-season harvest from before the freeze (October) to after the freeze (November and February) in the 1X management system resulted in lower harvestable biomass yield. Harvestable biomass was 22% lower in November and 30% lower in February compared to the 6.5 ton /acre yield achieved in October. Biomass losses due to delayed end-of-season harvest have been attributed to canopy lodging and abscised leaves in the November and February harvests. In contrast to the 2X management system, delaying the end-of-season harvest of switchgrass from October (before freeze) to November or February had no negative effect on biomass yield (average 6.6 tons/acre) when ‘BoMaster’ switchgrass was defoliated twice per year as in the 2X system (first harvest in June/July and the regrowth harvested in either October, November, of February). (See Figure 2.) In Figure 2, bars with different lowercase letters are statistically different for the 1X defoliation management system. For comparing 1X versus 2X at each end-of-season harvest timing, N.S. = not significant, ** = different at P value < 0.01.

Dry Matter Concentration of the Harvested Biomass at End-of-Season Harvest Timing

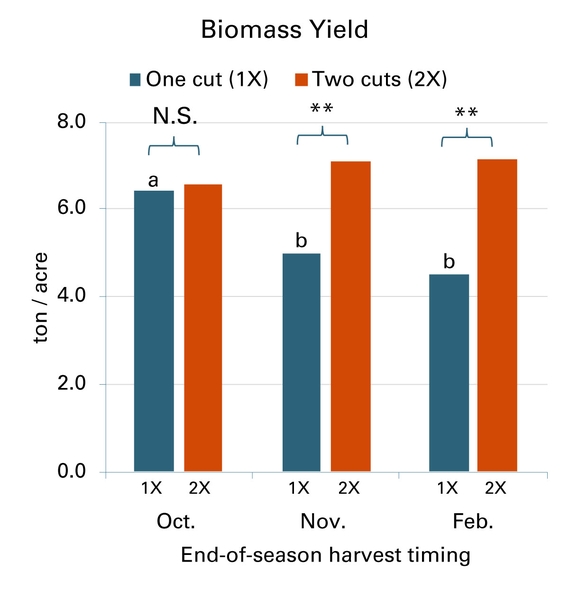

As a reference, for the mid-season June harvest of the 2X defoliation system, the dry matter concentration ranged from 23.6% to 28.4%. This is very wet material that must be dried for processing. For the biomass harvested at the end of the growing season, the dry matter concentration was greater for 1X in October, although the concentration was similar in November and February (Figure 3). When averaged between defoliation systems 1X and 2X, overall dry matter concentration increased approximately twofold when harvest at the end of the growing season was delayed from October (average 45.3%) to after freeze in February (average 89.3%) and was intermediate in November at 51.5%. The dry matter concentration levels reached in February are considered safe for biomass storage. Higher dry matter concentrations of biomass at harvest time are desirable because they can reduce the cost of artificial drying and the risk of spoilage when the biomass is stored or transported (Lewandosky and Kicherer 1997).

Nitrogen, Phosphorus, Potassium, and Ash Removal in the Harvested Biomass

Averaged across end-of-season harvest timings, total seasonal nitrogen, phosphorus, and potassium removals in the harvested biomass were at least twofold for the 2X system versus 1X. Removal of N was 122 lb/acre for 2X and 38 lb/acre for 1X. Phosphorus removal was 21 lb/acre for 2X and 8 lb/acre to 1X. Potassium removal was 190 lb/acre for 2X and 48 lb/acre for 1X. Examining the 2X defoliation system, approximately 80% of total N and 89% of total K removed in the harvested tissue were accounted for by the mid-season harvest in June.

The five ash components of Si, K, Ca, S, and Cl generally influence biomass conversion (Bakker and Elbersen 2005). Ash concentration was greatest in October (3.2%), intermediate in November (2.7%), and lowest in February (1.7%). Ash concentration was greatest for 2X (2.9%) and lowest for 1X (2.3%). Ash concentration of switchgrass has been reported to be at least threefold greater in the leaves than in the stems (Monti et al. 2008). Lower ash concentration due to delayed harvest at the end of the season may be attributed to leaf losses (Adler et al. 2006), although further study with ash is needed to specify the extent of leaf loss and to quantify which elements change over time.

Figure 2. Biomass yield of ‘BoMaster’ switchgrass as a function of defoliation management [one cut (1X; full season growth) or two cuts (2X; June/July and regrowth cut at end-of-season)] and harvest timing (October, November, or February) at the end of the growing season

(adapted from Rivera-Chacon et al. 2022)

Summary and Conclusions

A defoliation system for switchgrass with the first harvest by mid-season in June/July allows for delay of the end-of-season harvest from October to February with no penalty on biomass yield. Biomass yields averaged 6.5 tons/acre. Delaying the end-of-season harvest from October to November and February is an agronomic management tool that extends the window of bioenergy feedstock supply from the field directly to the bioprocessing facilities in North Carolina. This reduces the need for drying and potentially the need for storage, especially during the winter.

Acknowledgments

Financial support was provided in part by the Bioenergy Research Initiative of the North Carolina Department of Agriculture and Consumer Services.

References

Adler, Paul R., Matt A. Sanderson, Akwasi A. Boateng, Paul J. Weimer, and Hans-Joachim G. Jung. 2006. “Biomass Yield and Biofuel Quality of Switchgrass Harvested in Fall or Spring.” Agronomy Journal 98 (6): 1518–1525. ↲

Bakker, Robert R., and H. Wolter Elbersen. 2005. “Managing Ash Content and Quality in Herbaceous Biomass: An Analysis from Plant to Product.” In Proceedings of the 14th European Biomass Conference (pp. 210–213), Paris. ↲

Bekewe, Perejitei E., Miguel S. Castillo, and R. Rivera. 2019. “Harvest Management Effects on Canopy Height and Light Interception of ‘Performer’ Switchgrass and Its Relationship with Weed Infestation.” Crop Science 59 (3):1309-1316. ↲

Bekewe, Perejitei E., Miguel S. Castillo, Juan J. Acosta, and R. Rivera. 2020. “Defoliation Management Effects on Nutritive Value of ‘Performer’ Switchgrass.” Crop Science 60 (3):1682–1689. ↲

Burns, Joe C., and D.S. Fisher. 2012. “Steer Performance and Pasture Productivity Among Five Perennial Warm-Season Grasses.” Agronomy Journal 105 (1): 113-123. ↲

Burns, Jospeh C., Robbie D. Mochrie, and David H. Timothy. 1984. “Steer Performance from Two Perennial Pennisetum Species, Switchgrass, and a Fescue—‘Coastal’ Bermudagrass System.” Agronomy Journal 76 (5): 795–800. ↲

Fike, John H., David J. Parrish, Dale D. Wolf, John A. Balasko, James T. Green, Jr., Monroe Rasnake, and John H. Reynolds. 2006a. “Long-Term Yield Potential of Switchgrass-For-Biofuel Systems.” Biomass and Bioenergy 30 (3): 198–206. ↲

Lewandosky, Iris M., and Andreas Kicherer. 1997. “Combustion Quality of Biomass: Practical Relevance and Experiments to Modify the Biomass Quality of Miscanthus X giganteus.” European Journal of Agronomy 6 (3-4): 163–177. ↲

Monti, Andrea, Nicola Di Virgilio, and Gianpietro Venturi. 2008. “Mineral Composition and Ash Content of Six Major Energy Crops.” Biomass and Bioenergy 32 (3): 216–223. ↲

Mosali, Jagadeesh, Jon T. Biermacher, Billy Cook, and John Blanton, Jr. 2013. “Bioenergy for Cattle and Cars: A Switchgrass Production System that Engages Cattle Producers.” Agronomy Journal 105 (4): 960–966. ↲

Rentizelas, Athanasios A., Athanasios I. Tolis, and Ilias P. Tatsiopoulos. 2009. “Logistics Issues of Biomass: The Storage Problem and The Multi-Biomass Supply Chain.” Renewable & Sustainable Energy Reviews 13 (4): 887–894. ↲

Richner, J. M., R.L. Kallenbach, and C.A. Roberts. 2014. “Dual Use Switchgrass: Managing Switchgrass for Biomass Production and Summer Forage.” Agronomy Journal 106 (4):1438-1444. ↲

Rivera-Chacon, Raul, Miguel. S Castillo, Travis W. Gannon, and Perejitel Bekewe. 2022. “Harvest Frequency and Harvest Timing Following a Freeze Event Effects on Yield and Composition of Switchgrass.” Agronomy Journal 115 (1): 222-229. ↲

Sanderson, Matt A., James C. Read, and Roderick L. Reed. 1999. “Harvest Management of Switchgrass for Biomass Feedstock and Forage Production.” Agronomy Journal 91 (1): 5–10. ↲

Publication date: Dec. 5, 2024

AG-975

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.