Introduction

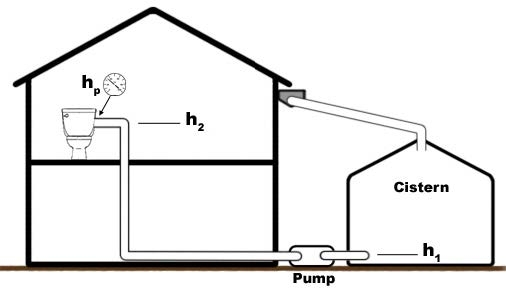

Water harvesting is the practice of capturing rainwater runoff, normally from a rooftop, and storing it in a tank or cistern for use around a home or business. While gravity flow from a cistern is generally enough to fill a bucket or to water a few nearby plants, most water-harvesting systems require a pump to convey the water from the holding tank to the spot where it will be used (Figure 1a and Figure 1b). Typical uses include watering plants, washing vehicles, flushing toilets, and washing clothes. A pump can increase the uses of the water-harvesting system and is required when consistent pressure is needed. Knowledge of how pumps operate and how they are selected will ensure that an efficient and appropriate pump is included in the water-harvesting system design.

Because pumps and plumbing systems are diverse, people installing water-harvesting systems should consult an experienced plumber to make sure all applicable codes are met and that there will be no damage to the pump or plumbing. Pump selection should be based on the flow and total head the pump is required to supply. Flow is the rate at which water travels through a pipe and often is measured in gallons per minute (gpm). Total head is a description of the energy required to move the water and is typically expressed in feet of water or pounds per square inch (psi). This publication reviews the pump selection process and at the end provides a sample calculation of flow and total head.

When properly configured, a rainwater-harvesting system delivers many benefits, including reduced flooding, improved water quality, reduced demand on a well or city water supply, and monetary savings. For more information on water-harvesting systems, see Permeable Pavements, Green Roofs, and Cisterns: Stormwater Practices for Low Impact Development, AG-588-06, part of the Urban Waterways series.

Pump Types

Pumps can be divided into two major categories: positive displacement pumps and dynamic pumps.

Positive displacement pumps operate by mechanically moving water by means of the action of a gear or piston and are able to produce high heads, but relatively low flows. They are generally used in hydraulic systems and in a number of specialty applications. Typical positive displacement pumps are piston and rotary pumps.

Dynamic pumps provide a continuous flow by developing a high fluid velocity and are able to produce high flows, but relatively lower heads. They are used to satisfy most general pumping requirements and typically require less maintenance than displacement pumps. Typical dynamic pumps include centrifugal and jet pumps.

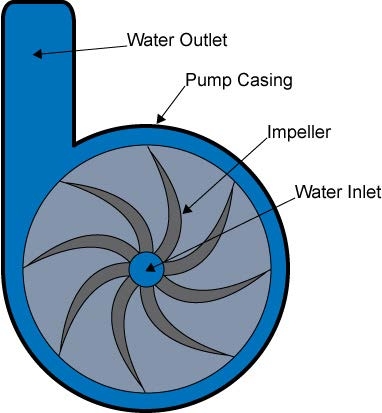

A centrifugal pump is suitable for most water-harvesting applications because of its relative simplicity, range of head and flows, and relative low cost. A centrifugal pump consists of a motor, pump casing, and impeller (Figure 2). The pump casing holds the impeller and channels water to and from the impeller. The impeller is a rotating vane structure that draws water into the pump casing, transfers energy to the water, and discharges it from the pump casing. The motor supplies the energy needed to rotate the impeller. For a specific pump casing, the motor and impeller often can be sized to meet head and flow requirements.

When a pump is installed above a cistern, problems with priming the pump and maintaining the prime arise. For this reason, either a submersible pump should be installed toward the bottom of the cistern, or a plumber should be consulted for specific pump requirements.

Calculation of Pump Demand

Flow — The flow for a pump system is determined by adding the flows of all fixtures, such as toilets, washing machines, sprinklers, etc., that may draw water from the cistern at the same time. For example, if a lawn needs to be watered with an impact sprinkler and a toilet is flushed while the sprinkler is running, the flows should be added for both uses. Table 1 contains typical flows for common fixtures. Specific flows for many devices can be found in the product literature and should be used in calculations when available.

Head — The “head” required of the pump is determined by calculating the total dynamic head of the system.

Equation 1. Total Dynamic Head (TDH)

TDH = hp + he + hf

TDH = total dynamic head (ft)

hp = operating head (pressure) required by fixture (ft)

he = h2 – h1 = elevation difference between pump and fixture (ft)

hf = friction loss in system (ft)

When the cistern feeds multiple fixtures, the total dynamic head should be calculated independently for each fixture. Because total dynamic head is not cumulative, the specifications for the fixture that demands the most head should be used in pump selection.

Pressure: HP The term “pressure” corresponds to the pressure required at the outlet to operate whatever device is being used. Typical minimum operating pressures for a number of devices are found in Table 1. For specific pressure requirements, consult the product literature. Equation 2 can be used to convert pressures in psi to feet of head. If the pressure selected is too low, the pump may not provide an adequate flow to operate the device; on the other hand, if an extremely high pressure is selected, it could damage seals and other plumbing equipment. The 2002 North Carolina state building code specifies that a water distribution system should not leak when tested at 100 psi.

Equation 2: Pressure Conversion

Feet of Head = PSI × 2.31

Elevation: HE The term “elevation” corresponds to the vertical distance water must be lifted to reach the location where it will be used. This distance is measured from the pump intake (h1) to the water outlet (h2) (Figure 3).

Friction: HF “Friction” accounts for energy losses associated with moving water through a plumbing network. The primary components are energy loss due to friction with the pipe walls and losses through elbows, valves, and other fittings. Manual calculation of friction is a complex process; therefore, information on typical friction losses for common pipe diameters is included in Table 2 and Table 3.

Friction loss due to pipe fittings can be calculated by using what is known as the equivalent length method. Look up the equivalent pipe length for the appropriate diameter of each fitting in Table 3. Add the equivalent lengths for all fittings encountered between the pump and the intended fixture for use in Equation 3.

To calculate the friction loss within the pipe, first find the friction factor (F100) that corresponds to the flow and pipe diameter of the plumbing in Table 2. Next, find the total linear distance of pipe that water must travel from the pump to the intended fixture. Use the calculated values in Equation 3 to determine the total friction loss.

Tables For Use In Friction Loss Calculations

(Tables 2 and 3 adapted from www.engineeringtoolbox.com)

Equation 3. Friction loss in system

hf = [ (LP + LF) / 100 ] x F100

Fp: Friction head loss (ft)

LP: Linear length of pipe (ft)

LF: Equivalent length for pipe fittings (ft)

F100: Friction loss per 100 feet of pipe from Table 2 (ft)

If the calculated friction loss is very high, it may be necessary to consider using pipes of larger diameter to prevent damage to the pump or plumbing system. A rule of thumb is to limit the water velocity in the pipes to 7.5 feet per second or less. If water will be pumped through a filter, the head loss through the filter should be included with the friction term. Because head loss due to filtration varies depending on the type of filter being used and the flow rate, the filter product literature must be consulted for specific head losses.

How to Select a Specific Pump

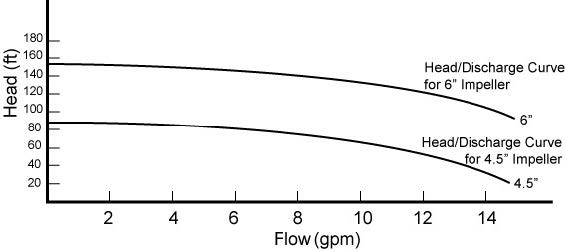

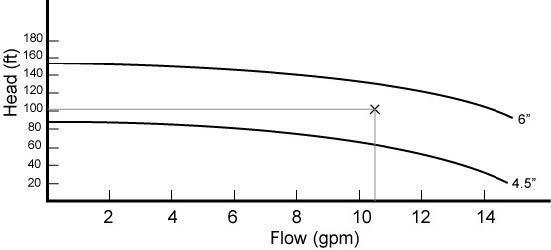

Once the required flow and total dynamic head are determined, a pump vendor can be consulted for information on specific pumps that are best suited for system demand. If a designer wishes to select his/her own pump or to understand why a vendor recommends a specific pump, knowledge of “pump curves” is required (Figure 4). A pump curve provides a description of pump performance and can be obtained from a pump manufacturer or vendor.

While the publication of pump curves varies, depending on the source, the most common curve is the head/flow curve. This curve illustrates what flow the pump will supply for a given head requirement. The pump is designed to operate at a point somewhere along this curve. It is important that the target head and flow lie either on or below this curve. If the target head and flow lie above and to the right of this curve, the pump will not be able to supply enough water to meet design requirements. For best overall efficiency, the target discharge should be in the middle third of the curve.

Pump Accessories

Depending on the water-harvesting application, some pump accessories may be needed. Consult a pump vendor to determine which accessories are necessary and compatible with a specific pump.

Pressure tank – The tank stores pressurized water to prevent the pump from cycling on and off to meet small demands; it also supplies a constant pressure.

Pressure switch –This device engages the pump when a pressure drop is observed and disengages it when there is no demand. For example, the pump will engage to supply water when a faucet is opened and disengage when no water is being used.

Check valve – The internal check valve prevents water from flowing back through the pump when it is not running. Some pumps do not have these valves. Consult a pump vendor or plumber to determine if additional check valves are needed.

Float level switch – This switch, when installed in the cistern, can prevent damage to the pump by disengaging the pump when the cistern runs dry or cistern water falls below a predetermined level.

Throttling valve – This device is intended to control the flow and pressure of water exiting the pump and is typically in the form of a gate valve. Special control systems can be installed to maintain a constant output despite changing water levels within a cistern.

Example: Choosing a Pump for a Water-Harvesting System

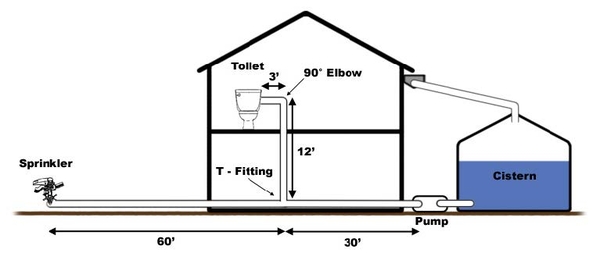

An aboveground water-harvesting cistern is installed at a home in coastal North Carolina. The cistern will be used to flush a toilet on the second floor of the home and to run an impact sprinkler for the lawn. All pipes in this example are ¾ inches in diameter. Select a pump that meets the needs shown in Figure 5.

Required Flow

From Table 1*, the required flow is 6 gpm for the toilet and 4.5 gpm for the impact sprinkler. It may be necessary to operate both fixtures at the same time; therefore:

Total Peak Flow = 6 gpm + 4.5 gpm = 10.5 gpm

Required Total Dynamic Head

Because there are 2 fixtures for this system, the required total dynamic head for each fixture must be calculated independently.

Toilet

he = h2−h1 = 12 ft (from Figure 5)

hp = 46 ft (Table 1)

Friction

LF = 5.0 (3/4” Tee – Branch Flow, Table 3) + 2.0 (3/4” 90° Elbow, Table 3) = 7.0 ft

LP = 30 + 12 + 3 = 45 ft (Adding lengths of pipe segments)

hf = [ (45 + 7.0) / 100 ] x 8.85 (Friction factor for ¾” pipe at 6 gpm , Table 2) = 4.6 (Equation 3)

Total Head Requirement = 12 + 46 + 4.6 = 62.6 ft (Equation 2)

*Sources for numbers are noted in parentheses

Impact Sprinkler

he = h2−h1 = 0 ft (from Figure 5)

hp = 93 ft (Table 1)

Friction

LF = 1.4 ft (3/4” Tee – Straight Flow, Table 3)

LP = 30 + 60 = 90 ft (Adding lengths of pipe segments)

hf = [ (90 + 1.4) / 100 ] x 8.85 = 8.1 (Equation 3)

Total Head Requirement = 0 + 93 + 8.1 = 101 ft (Equation 2)

Because the impact sprinkler has a higher head requirement than the toilet, the impact sprinkler head value will be used for the pump design.

Two pump curves are shown in Figure 6. Find the design point by locating the intersection of the required head and flow, denoted by the “x” in the graph. Notice that the design point lies above the curve for the 4.5” impeller; therefore, that impeller size will not meet the system demand. The design point lies below the curve for the 6” impeller, indicating the 6” impeller will provide an adequate water supply. Because the 6” impeller can supply the required head and flow, this pump will satisfy the demands of this water-harvesting system.

Internet Resources

NC State Extension Publications:

Rainwater Harvesting: Guidance for Homeowners

Mosquito Control for Rainwater Harvesting Systems

Texas A&M's Rainwater Harvesting Website

Publication date: Oct. 1, 2006

Reviewed/Revised: Oct. 7, 2024

AG-588-08

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.