Introduction

Rainfall is the principle source of water for North Carolina crops. However, many farmers are turning to irrigation to supplement precipitation. There are many types of irrigation systems. But, most farmers have limited choices for their particular farm or field. Some systems are inherently more water and energy efficient while others are designed to overcome limitations such as irregular field shapes, sloping land, or limited water supplies. All of these factors should be considered before selecting a particular type of system.

Hand-move systems are normally used to irrigate small fields. Solid-set and permanent sprinkler irrigation systems are used for irrigation, frost/freeze protection, evaporative cooling, and land application of nutrient-rich effluent. Selection and management considerations for hand-move solid- set and permanent sprinkler irrigation systems are discussed in this article. Selection and management criteria for other types of irrigation systems are presented in articles EBAE 91-150: Self- Propelled Gun Traveler Irrigation Systems, EBAE 91-151: Center Pivot and Linear Move Irrigation Systems, and EBAE 91-153: Low Volume Irrigation Systems.

Sprinkler irrigation systems have been available for more than 70 years. The early systems used lightweight steel pipe and nonrotating sprinklers. Rotary impact sprinklers were introduced in the late thirties. However, it was not until after World War II, when aluminum pipe became available, that portable hand-move system became practical. Most of the early rotary impact sprinklers were low capacity, medium pressure, and constructed of brass. Some companies supplied gun sprinklers, but early models were not very satisfactory, because of the high application rate and potential for runoff. Over the years, the trend has been toward larger sprinklers. Several companies now supply a low capacity (i.e., low application rate) gun sprinkler which has reduced some of the runoff problems typically associated with gun type sprinklers. Sprinklers are now available with plastic, brass, aluminum, and some stainless steel components. Improvements in bearings contribute to longer life and less maintenance. Quality control has also improved.

The major change in aluminum pipe has been a trend toward thinner wall aluminum pipe and stronger alloys. Couplers and gaskets have been improved to reduce leaks at joints. The number of coupler manufacturers has been reduced. Most of these changes have occurred because of the introduction of other types of irrigation systems such as self-propelled gun travelers, center pivots, linear move, low volume, and sub-irrigation. Sprinkler spacing’s for portable irrigation systems range from 40 feet by 40 feet for small sprinklers to greater than 200 feet by 200 feet for gun sprinklers. Spacing’s may be square, rectangular, or triangular. Spacing’s are usually about 60 percent of sprinkler wetted diameter, but may need to be adjusted for wind conditions. Single- or double-nozzle sprinklers may be used. The double- nozzle sprinkler generally provides better uniformity, because the second nozzle provides water close to the sprinkler. Smaller sprinklers, because they are less affected by wind, provide better uniformity than gun sprinklers.

However, the labor required for moving pipe when smaller sprinklers are used is increased considerably. (Smaller sprinklers require more lateral lines.)

Hand-Move Portable Systems

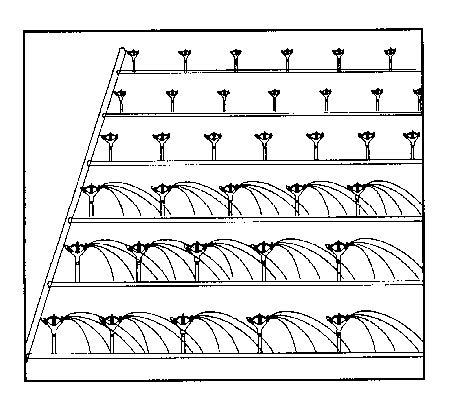

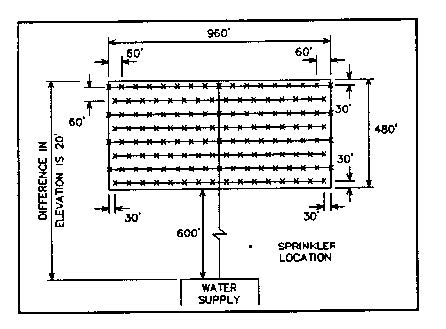

Figure 1a shows a typical layout of a portable hand-move aluminum pipe system. Two laterals are operated at one time. Spacing between sprinklers is 60 feet and spacing between laterals is 60 feet. The first and last sprinklers on each lateral are 30 feet from the edge of the field. This is done to provide more uniform water distribution around the edges of the field.

Laterals and sprinklers are typically moved twice per day which requires 4.5 days to irrigate the 30-acre field shown in Figure 1b. Each setup and movement of the pipe is referred to as a "set". Approximately 22.5 man-hours are required to move pipe each time the field is irrigated. For the field length and shape shown, the lateral pipe size required is 4-inch, and the main line size required is 6-inch. A pump capacity of 425 gallons per minute (gpm) would supply an application rate of 0.28 inches per hour when two laterals are irrigated per set. When operated for four hours (l/2 day per set), the total application to each set is just over one inch of water.

In the above example, only one inch of water could be applied per week, unless the pipe was moved and the system operated over the weekend. Thus, the system shown only has the capacity to supply about one-half the crop water requirements during peak water use periods. (Peak water use is nearly 0.3 inches per day or 2 inches per week for most crops grown in North Carolina.) In terms of size (number of acres irrigated), the 30 acre example is a relatively small system indicating that hand-move portable systems are not practical for irrigating large acreage.

There are, however, practical applications for portable, hand-move systems. Some practical applications include the irrigation of:

- plant beds such as tobacco or sweet potato beds, which are typically moved from one year to the next;

- small acreage of high cash-value crops which also need to be rotated from year to year making solid set or permanent systems unsuitable;

- small scattered fields separated by non-cropped areas; and

- establishment and maintenance of lawns, turf areas, fruit and/or nursery trees and/or shrubs that require only an occasional irrigation, most often immediately after seeding or transplanting.

The labor required for moving pipe, and the introduction of other types of irrigation systems have diminished the popularity of hand-move potable systems. Instead, growers have shifted to solid-set and permanent systems.

Solid-Set and Permanent Irrigation Systems

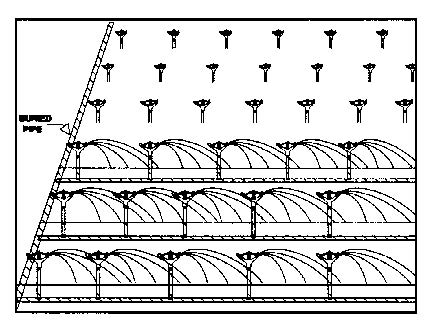

The solid-set system uses aluminum pipe, but instead of moving lateral lines once or twice a day as is done with portable systems, enough lateral pipe is purchased so that pipe may be left in place during the irrigation season. Main line for the solid-set system can be aluminum pipe or buried polyvinyl chloride (PVC) plastic pipe.

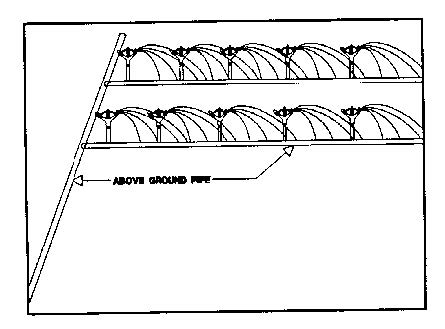

The permanent system normally uses buried main and lateral lines. However, some growers use above ground PVC plastic lateral lines. These systems are used more in orchards where the system is installed after the orchard is planted and in some container nursery operations. Permanent systems have been used for many years to irrigate turf areas such as golf courses, recreational playing fields, and commercial and residential turf. In more recent years, these systems have been used for agricultural irrigation to include nursery crop production.

Most of the solid-set and permanent systems for agricultural irrigation (including chemigation and fertigation) are used on high value crops such as nursery crops, tree fruits, small fruits, vegetables, and, to a small extent, tobacco. Many of the systems for fruits and vegetables are also used for environmental modification such as frost/freeze protection and crop cooling.

These uses require a dependable water supply during the critical environmental period. For crop cooling, it may be possible to cycle the system on and off to reduce the total volume of water pumped.

Solid-set and permanent systems designed for frost/freeze protection and crop cooling normally use small sprinklers and application rates in the range of 0.12- to 0.25- inch per hour. Normally, single nozzle sprinklers are used on spacing’s of 40 feet by 40 feet to 66 feet by 72 feet. Spacing’s are normally 50 to 65 percent of sprinkler wetted diameter. Lateral spacing’s and sprinkler spacing’s on the lateral are adjusted to meet row and tree spacing’s. Sprinkler pressures are normally 10 to 15 psi higher than those used for irrigation to give small droplets and therefore, better coverage and higher sprinkler rotation speeds.

Frost/freeze protection using sprinkler irrigation operates on the principle of latent heat of fusion. Water, as it changes state from liquid to solid, generates heat. The heat being given off maintains the temperature of the plant near 32 F if adequate water is being applied. Higher sprinkler pressure provides smaller droplets and faster sprinkler rotation and, therefore, better protection (i.e., smaller droplets freeze faster than large droplets). But, windy conditions reduce the added protection of smaller droplets because wind causes evaporation. The heat required to evaporate water is 7.5 times the heat given off when water freezes. Just as smaller droplets freeze faster which improves frost/freeze protection, smaller droplets also evaporate faster. Thus high pressure resulting in small droplets should not be used where windy conditions occur frequently. Also, lateral line spacing’s and sprinkler spacing’s along the lateral should be reduced where windy conditions are prevalent. Good frost/freeze protection requires that liquid water be available on the plant at all times.

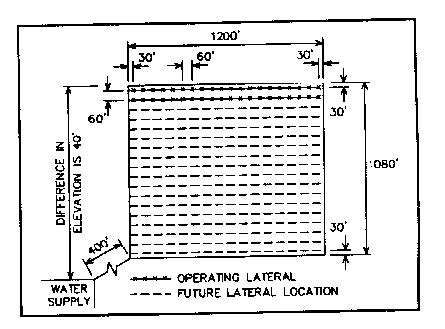

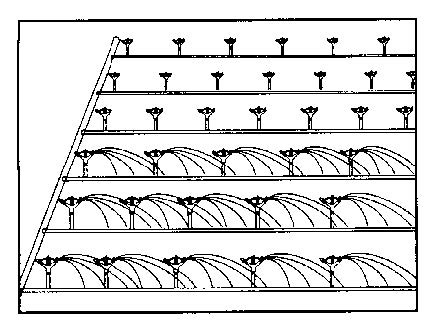

Figure 2a shows a typical layout for a solid-set system for frost/freeze protection of strawberries. A triangular sprinkler spacing is used. Sprinklers are spaced 60 feet on the lateral and laterals are 60 feet apart. The first and last laterals are 30 feet from the edge of the field. Using the triangular spacing requires that the first and last sprinkler on every other lateral be on the edge of the field. Lateral pipe size is 2-inch aluminum. Main line size is 8-inch aluminum. Pump capacity required to provide frost/freeze protection for the acreage and setup shown in Figure 2b is about 900 gpm.

In the last several years, a number of solid-act and permanent systems have been installed for land application of nutrient-rich effluent. Several agencies are promoting this practice as an environmentally safe method to utilize this resource. Some land application systems are being installed on golf courses and public turf areas. This is an approved practice in many states.

North Carolina Cost Share funds are being used to fund one intensively grazed, land application of nutrient-rich effluent demonstration in each county. These areas are normally grazed, but producers may elect to produce hay crops rather than use the fields for grazing.

Sprinkler spacing’s on land application systems are typically in the range of 80 feet by 80 feet, using single-nozzle sprinklers. Other spacing’s can be used and some of the sites use gun sprinklers on wider spacing’s. Normal spacing is 60 to 70 percent of sprinkler wetted diameter.

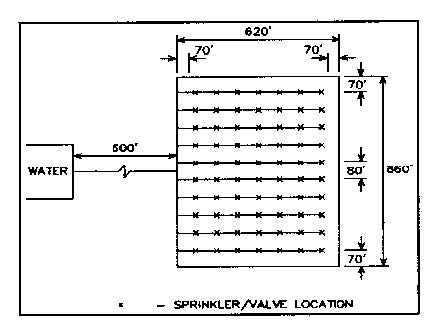

Figure 3a shows a typical layout for a permanent irrigation system for land application of nutrient-rich effluent. Sprinkler spacing is 80 feet on the lateral. Spacing of laterals is also 80 feet. Lateral pipe size is 2.5 inch. Main pipe size is 3 inch. One lateral is usually operated at one time. Sprinklers may be located on each lateral; or, sprinklers may be moved from one lateral to another lateral. By moving sprinklers, initial system cost is reduced. To operate one lateral as shown, pump capacity required is about 120 gpm. Note that there is a 70-foot border around the edge of the field to insure that no effluent is applied outside the field. (Figure 3b).

Design Considerations

General guidelines ("rules of thumb") have been established and should be followed when designing hand-move, solid-set, and permanent systems. For portable hand-move aluminum pipe systems, friction loss in the main and/or supply pipe should not exceed 2.0 psi for 100 feet of (fps) pipe. For lines that are greater than 1500 feet in length, friction loss should not exceed 1.0 to 1.5 psi per 100 feet. For PVC plastic pipe main and/or supply lines, flow velocity is the limiting factor rather than friction loss. Velocity should not exceed 5 feet per second to prevent pipe failure due to water hammer. Water hammer describes the buildup and sudden release of pressure that occurs when air is trapped in the pipe. The buildup and release of the pressure increases as the velocity of the flowing water increases.

Friction loss in aluminum and plastic lateral lines should not exceed 20 percent of recommended sprinkler operating pressure. Following this rule will assure reasonably uniform water distribution. As sprinkler pressure is reduced, due to friction loss down the lateral line, the volume of water applied by the sprinkler and the diameter of coverage is reduced.

Energy Conservation

Most portable, solid-set and permanent sprinkler systems are medium to moderately-high in energy consumption, depending on whether small sprinklers or gun sprinklers are used.

Certainly, gun sprinklers will require higher pressures, increasing the power required. Many of the portable systems use gun sprinklers. Some growers are willing to trade off the higher energy costs for the savings in labor costs. There are some gun sprinklers that will operate satisfactorily at lower pressures and some growers are using these, but they have reduced radius of coverage and, therefore, higher application rates, assuming equal flow rates.

There are some low pressure impact sprinklers that have been marketed for the last several years. They also have reduced radius of coverage and this may increase the application rate.

Fuel costs (and conversely fuel savings) are computed based on the energy required to deliver the required flow rate at the desired operating pressure. To compute horsepower (Hp) requirements, use the formula shown in the box at the top of the next column.

\(Horsepower=[TDH\ (feet)×Flow\ (gpm)]/[3960×Pump\ Efficiency]\)

Total dynamic head (TDH) or operating pressure at the pump includes the sum of the following:

- sprinkler operating pressure

- friction loss in the main line

- friction loss in the lateral line

- elevation difference between the water supply and the highest point in the field, and

- height of sprinkler above the ground (riser height)

Flow is the rate water is being delivered to the sprinklers. After computing TDH, a pump efficiency should be assumed so that horsepower can be computed using the above formula. Refer to Extension Publication AG-452-6: Pumping Plant Performance, for a discussion of recommended pump efficiencies to select. Once the power requirements have been determined, the fuel cost can be computed (again, refer to AG-452-6 for more information). By comparing costs of several operational and system alternatives (i.e., operating pressure, low pressure sprinklers, etc.) the most energy efficient system can be identified for the given situation.

Summary

If proper design guidelines are used and sprinklers are operated at the manufacturers' recommended mid-range of operating pressures, these systems should be reasonably energy efficient. Pump selection should include the use of high efficiency pumps and matched power units.

Hand-move, solid-set, and permanent irrigation system can be energy efficient. Solid-set and permanent systems are normally more energy efficient than portable hand- move systems.

Unfortunately, some of the older systems have sprinklers, pumps, and power units that are 20 or more years old and need replacing. Many growers have replaced sprinklers and often have several sizes of orifices on the same system.

Growers often purchase used equipment and combine components from several systems to make one system. When this is done, little opportunity exists to incorporate recommended design guidelines to properly size and match system components.

If your system is more than three years old, you should have it evaluated. Contact your county Extension office or local irrigation dealer for more information and assistance. Making a profitable decision about repairs like when to replace worn system components requires a complete economic analysis of existing system performance and the projected cost of alternatives.

Publication date: June 1, 1996

Reviewed/Revised: Nov. 15, 2024

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.