Introduction

Irrigation requires large quantities of energy. Most of the energy is consumed by the pumping plant. High pumping costs usually result from poor maintenance, excessive wear, or mismatched components. Annual energy costs run about $25 per acre in North Carolina where application rates average 8 inches per acre per year. Energy cost may be several times higher when water is applied with poorly maintained and operated systems.

This publication discusses the causes of poor irrigation system performance. Some of these causes can be identified and corrected by the irrigator. Others require specialized evaluation equipment, and the corrections should therefore be performed by specially trained technicians.

The energy required to pump a given quantity of water is affected by:

- pumping lift-the vertical distance from the water source to the discharge point (elevation) in the field;

- operating pressure-pressure on the discharge side of the pump necessary to provide the proper pressure to sprinkler nozzles in the field;

- pumping plant efficiency.

Energy requirements decrease as pumping lift and operating pressure decrease and pumping plant efficiency increases. To maximize pumping plant efficiency, the components should be matched to the site-specific conditions of pumping lift, operating pressure, and flow rate.

Pumping Plant Components

Irrigation Pumps

Pump designs vary depending on the application. Centrifugal pumps (self-priming or non-self-priming) are used when pumping water from surface sources and shallow wells (Figure 1). Turbine pumps (vertical-shaft or submersible) are used when pumping from deep wells (Figure 2). Specific features of each pump are discussed in Extension publication AG-389, Water Supplies for Subirrigation.

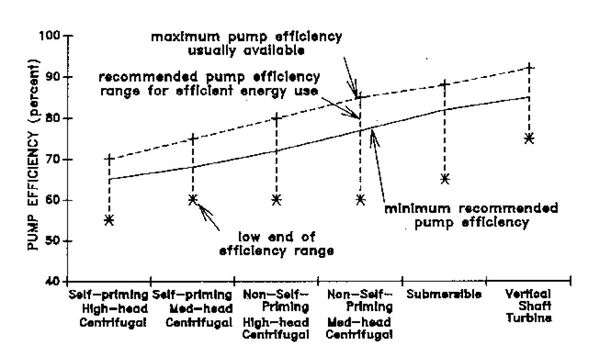

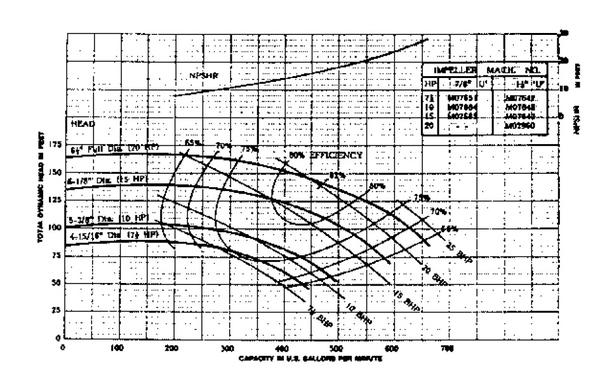

Some pumps are more efficient than others (Figure 3). Values are representative for most pumps, but there are some exceptions in all categories. Pump characteristic curves should be consulted to select a pump that provides the desired efficiency for a particular set of operating conditions.

Most types of pumps are available over a wide range of operating efficiencies. Pump efficiency is the ratio (expressed as a percentage) of the water horsepower of the discharge water divided by the energy delivered to the pump by the power unit. Turbine pumps tend to have the highest efficiencies but over a relatively narrow range of operating conditions. Efficiencies of some vertical-shaft turbine pumps approach 90 percent.

Submersible pumps are generally lower in efficiency. Depending on the size and design, they are typically 3 to 5 percent less efficient than vertical-shaft turbine pumps of the same capacity. Centrifugal pump efficiencies vary the most, ranging from 55 to 85 percent. As a general rule, high-head-pressure centrifugal pumps-those operating at a pressure greater than 40 pounds per square inch (PSI) tend to be less efficient than moderate-head pumps operating at a pressure less than 40 PSI. As the size of centrifugal pumps decreases, the efficiency decreases. Also, some of the less expensive small pumps are fairly low in efficiency. Self-priming centrifugal pumps tend to be least efficient.

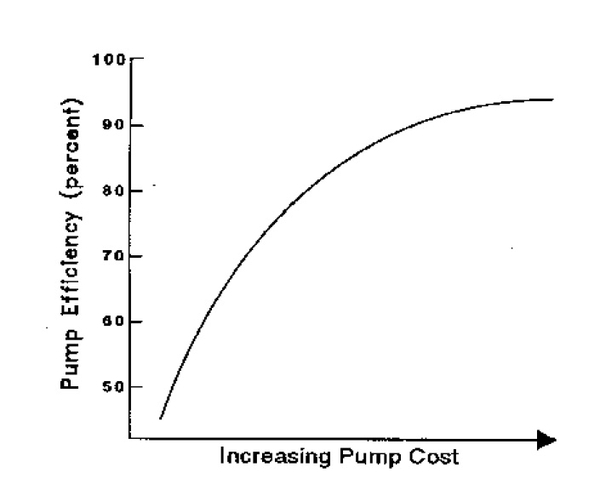

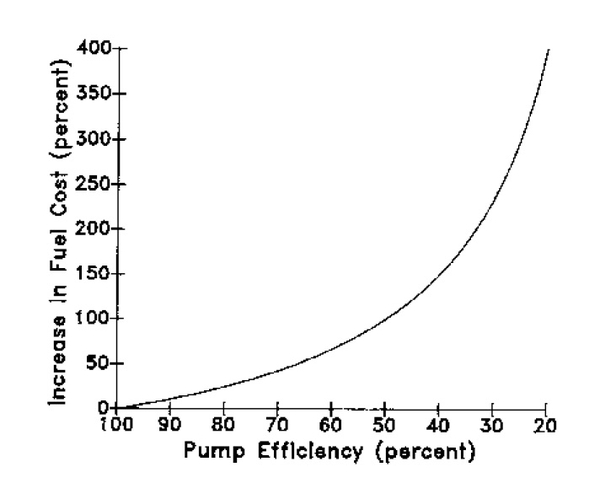

Normally, pump cost increases as efficiency increases (Figure 4). Operating costs for fuel increase as pump efficiency decreases (Figure 5). Thus, savings in operating costs of more efficient pumps usually compensate for higher initial costs after a few years of use. Target pump efficiencies should be in the range from 75 to 85 percent.

Once the operating pressure (head) and system capacity (flow rate) have been determined, consult pump characteristic curves to select the most efficient pump for the specific conditions. Most pump manufacturers provide characteristic curves for each of their pumps. These curves show the relationship between head, horsepower, capacity, and efficiency. Irrigation pumps should be selected to match specific conditions of pumping rate and operating pressure (expressed as total dynamic head, or TDH).

Figure 6 shows a typical characteristic curve for an electric-motor-driven pump.

Pump wear and reduced efficiency occur quickly when the water contains sand or other abrasives. Many wells in North Carolina are drilled into water-bearing sand or sandstone. To prevent movement of sand into the pump, it is equipped with an intake screen. Improper sizing of well-screen openings will accelerate pump wear and reduce its efficiency. Improper screening of the suction line of centrifugal pumps can allow abrasives in surface water to enter. When water is pumped from a surface source, pond sediments may be picked up, thus accelerating pump wear, especially near the end of the irrigation season when the water level is low.

Power Units

Power units are of two basic types: electric motors and internal combustion engines (either direct-drive engines adapted solely for irrigation or tractors with a power takeoff (PTO) used to drive a pump).

Where electricity is available, it is the most efficient power source. As shown in Table 1, the efficiency of electric motors ranges from 80 percent for motors under 7.5 horsepower to over 90 percent for motors of 75 horsepower or larger. One disadvantage of electrical systems is that electric lines in many rural areas do not run near the water source, and three-phase power is often less available in these areas. Most electric companies require three-phase power for motors that deliver more than 5 or 10 horsepower, depending on the application and the company providing the service.

| Electric Motor Size (horsepower) | Full Load Motor Efficiency (percent) | Matched Size Pump Efficiency* (percent) | Typical Attainable Pumping Plant Efficiency** (percent) |

| 3-5 | 80 - 86 | 55 - 65 | 44 - 56 |

| 7.5 - 10 | 85 - 89 | 60 - 70 | 51 - 62 |

| 15 - 30 | 86 - 90 | 65 - 75 | 56 - 68 |

| 40 - 60 | 88 - 92 | 70 - 80 | 62 - 74 |

| 75 and larger | 90 - 93 | 75 - 85 | 68 - 79 |

*Values shown are typical for centrifugal pumps. Submersible pumps range 3 to 5 percent higher and turbine pumps range 5 to 10 percent higher for sizes under 75 horsepower. Above 75 horsepower, a few centrifugal pumps may approach efficiencies of 88 percent, whereas large submersible and turbine pump efficiencies peak at about 90 percent. Since pump efficiencies are quite variable depending on type, manufacturer, and size, consult pump performance curves for a specific application. ↲

**Values obtained by multiplying power source efficiency range (in this case, for an electric motor) by the matched pump efficiency range. Internal combustion engine drives are available to meet most power requirements of 3 horsepower or more. Generally, small engines are gasoline operated, whereas larger units are usually diesel. Most power units with less than 40 horsepower plus some of the larger diesel units are air cooled. ↲

Internal combustion engines are inefficient. Gasoline engines are only 20 to 26 percent efficient, while diesel efficiencies range from 25 to 37 percent. The advantage of the diesel's higher efficiency and longer operating life must be balanced against the higher initial cost. If the engine is to be operated over a long period of time, the diesel engine is usually the most economical, but if the pump is operated for only a few hours each year, a gasoline engine is more economical.

Performance standards for engines and pumping plants are published annually in the Nebraska Tractor Test Report. The report contains performance data for most agricultural power equipment marketed in the United States. These unbiased performance data are determined by University of Nebraska engineers for equipment adjusted to manufacturer's recommendations. Standards for irrigation pumping plants are given in Table 2.

| Energy Source | Energy Unit |

Horsepower-Hours (1) Per Unit of Energy |

Water Hp-hr (2) Per Unit of Energy (3) |

|---|---|---|---|

| Diesel | Gallon | 16.7 | 12.5 |

| Gasoline (4) | Gallon | 11.5 | 8.66 |

| Propane (4) | Gallon | 9.2 | 6.89 |

| Natural Gas (6) | 1,000 cu ft | 88.9 (5) | 66.7 |

| Electricity | kWh | 1.18 (7) | 0.885 (8) |

Source: Dorn, T.W., P.E. Fishbach, D.F. Eisenhauer, J.R. Gilley, and L.E. Stateson, It Pays to Test Your Irrigation Pumping Plant. Publication EC-713. Lincoln: University of Nebraska, Cooperative Extension Service.

- Horsepower-hours is the work being accomplished by the power unit with losses considered. ↲

- Water horsepower-hours is the work being accomplished by the power plant at the Nebraska Performance Criteria. ↲

- Based on 75 percent pump efficiency. ↲

- Taken from Test D of Nebraska Tractor Test Reports. Drive losses are accounted for in the data. Assumes no cooling fan. ↲

- Manufacturers' data corrected for 5 percent gear-head drive loss and no cooling fan. ↲

- Assumes natural gas energy content of 1,000 Btu per cubic foot. ↲

- Assumes 88 percent electric motor efficiently. ↲

Pump Drive

The pump drive transfers energy from the power unit to the pump. Electric motors are frequently coupled directly to the pump through the motor line shaft. When properly aligned and lubricated, direct drives introduce very little energy loss. In some cases, power is transmitted through a belt drive so the pump speed can be changed. Belt drive efficiencies are typically between 85 and 95 percent.

When the pump is driven by an internal combustion engine, a gear drive may be necessary to convert engine speed to proper pump speed. Engine-driven centrifugal pumps drawing water from surface sources are usually close coupled (Figure 7). Close-coupled gear drive efficiencies should exceed 98 percem. Engine-driven turbine pumps (Figure 8) require a right-angle drive to change the horizontal direction of the engine drive shaft to the vertical direction of the pump line shaft. Right-angle drive efficiency is about 95 percent.

Inefficient pumping plants cost more to operate. Low pumping plant performance usually results from (1) an inefficient pump or power unit, (2) mismatching of the pump and power unit, or (3) a combination of these.

Pumping plant efficiency can be tested to provide information on adjustments or retrofits needed to improve efficiency. To determine the pumping plant efficiency, measure pumping lift, discharge pressure, flow rate, and fuel usage. Fuel usage can be read directly from the electric meter or by measuring the liquid level in the fuel tank over a specific time period. A pressure gauge is usually installed on the discharge side of the pump to indicate operating pressure. Some systems have in-line flow meters to indicate pumping rate. Thus, the only equipment needed is a device to measure water level (relative to the pump) at the water source and a flow meter if one is not present.

Once the above measurements have been made, the pumping plant performance can be computed from the relationships in the box on the following page.

An example of a pumping plant performance analysis is shown in Table 3. In this example, the pumping plant is performing at 86 percent of the Nebraska Standard. For additional explanation of the terminology used in Table 3, consult Extension Publication AG-452-5, Irrigation Management Strategies to Improve Water and Energy Efficiencies.

In establishing performance standards, it is recognized that individual pumping plant components are not 100 percent efficient.

The performance standards were established to compare and evaluate systems based on "reasonable efficiency expectations." For an electrically driven pumping plant, the standard is based on a motor efficiency of 88 percent and a pump efficiency of 75 percent (see the footnotes to Table 2), resulting in an actual efficiency of 66 percent (0.88 x 0.75 = 0.66). Thus, an electrically driven pumping plant performing at the standard is only 66 percent efficient in converting electric energy to mechanical energy. In the example, performing at 86 percent of the standard, the absolute pumping plant efficiency is only 57 percent (0.86 x 0.66 = 0.57).

Total Dynamic Head (TDH) — the "head" or pressure needed at the pump to move the required volume of water (in gallons per minute) through the system and discharge it at the recommended nozzle pressure. (TDH is the total of all head losses.)

Eq. 1. Total dynamic head (feet) = static head (feet) + dynamic head (feet)

Water Horsepower — the power required to deliver the desired flow rate of the desired discharge pressure.

Eq. 2. Water horsepower (WHP) = flow (GPM) x TDH (feet) / 3960

Fuel Consumption (FC) — the rate at which energy is consumed to deliver the required water horsepower (measured in gallons per hour for internal combustion engines or kilowatt-hours for electric motors).

Energy Efficiency — the water horsepower delivered divided by the fuel consumption rate.

Eq. 3. Energy efficiency = water horsepower/fuel consumption

Energy-use Efficiency or Performance Rating — the energy efficiency divided by the performance standard.

Eq. 4. Energy-use efficiency= energy efficiency/performance standard

Interpreting Pumping Plant Performance

System Evaluation

- Calculate total dynamic head from equation 1.

TDH = operating pressure + vertical lift = 80 psi (2.31 feet/psi) + 5 feet = 190 feet

- Calculate water horsepower from equation 2.

WHp = TDH × flow / 3960 = 190 feet × 120 gpm / 3960 = 5.76 Hp-hr

- Calculate energy efficiency from equation 3.

Energy efficiency = water horsepower/ fuel consumption = 5.76 Hp-hr / 7.53 kWh = 0.76 Hp-hr/kWh

- Determine performace standard efficiency from Table 2 for electric system.

Performance standard for electric = 0.885 Hp-hr/kWh

- Calculate energy-use efficiency (performance rating) from equation 4.

Energy use efficiency = energy use/ performance standard= 0.76 Hp-hr/kWh / 0.885 Hp-hr/kWh = 0.86 or 86 percent

There is no exact efficiency level that indicates when adjustments or repairs are necessary. The cost of efficiency improvements must be balanced against the possible energy savings. Factors that influence the decision are:

- the extent of poor performance

- fuel cost

- hours of operation each year

- specific conditions of operating pressure and pumping rate.

Normally, adjustment costs are small, and any resulting improvement in pumping plant performance will pay dividends within one year.

Repair or replacement of minor components is more costly, and payback may take one to three years. Minor repairs are usually justified when the system performance is between 60 and 80 percent of the Nebraska Standard. For the example system operating at 86 percent of the standard, adjustments are warranted but repair or component replacement is not.

Replacement of major components, such as the engine, motor, or pump or changing to a more efficient system are most costly.

Normally, replacement of major components is not warranted unless the performance rating is less than 60 percent of the standard. The payback period for replacement of major components is typically five years or more.

Analyzing Pumping Plants Driven By Electric Motors

The pumping plant analysis indicates whether or not overall performance is acceptable but does not indicate which component is responsible if overall efficiency is low. Overall pumping plant efficiency can be computed by multiplying the efficiencies of the individual components. Electric motors are relatively efficient and reliable. Poor pumping plant performance can usually be attributed to low pump efficiency.

When the pumping plant test indicates poor performance, assume a reasonable motor efficiency (usually 90 percent) and then compute the pump efficiency. In the example, the overall pumping plant performance was 86 percent of the standard. The absolute pumping plant efficiency was 57 percent. Assuming a motor efficiency of 90 percent, the absolute pump efficiency is 63 percent (the overall efficiency divided by the motor efficiency, 0.57/0.90 = 0.63). This value should be compared with the appropriate pump characteristic curve (like the one shown in Figure 6) to determine if the pump is being operated outside its highest efficiency range.

Figure 6. Typical pump characteristic (performance) curve for a motor-driven pump. There is a narrow range

(shaded area) of pressure and volume within which the pump will perform at maximum efficiency. This pump is best

suited for operation in the range from 400 to 500 gallons per minute (GPM) at a TDH of 100 to 150 feet with a suction

lift (NPSHR) of 14 to 19 feet. In this operating range, the pump efficiency is greater than 80 percent. Maximum

efficiency for this pump is 82 percent when pumping 460 to 480 gallons per minute at a TDH.

The following are likely causes of low pump efficiency:

- Low pressure and low flow rate: These conditions indicate excessive pump wear. Internal pump components should be evaluated by a qualified representative of the pump manufacturer.

- Low pressure and high flow rate: These conditions indicate an excessive number of sprinklers operating at one time or excessive wear of sprinkler nozzles. Reduce the number of sprinklers until the proper flow rate is reached.

- If the pressure is still below standard, the pump is worn.

- If pump efficiency returns to the recommended range, check nozzles for wear and replace them if necessary.

- If there is no evidence of excessive nozzle wear, too many sprinklers are operating at one time. Take corrective action by

- reducing the number of sprinklers

- if possible, adjusting the pump to deliver more pressure for revised flow with all sprinklers operating at one time, or

- replacing the pump with one rated for the desired operating conditions.

- High pressure and low flow: These conditions indicate that the discharge may be partially blocked or there are not enough sprinklers operating. Increase the number of sprinklers.

- If the problem is not corrected, look for blockage on the discharge side of the pump.

- If efficiency improves to the rated range, continue the operation with added sprinklers.

- If operating pressure and flow are in the high-efficiency range but efficiency is low, this indicates a change in suction lift, usually resulting from a drop in water level at the water supply or a blocked intake (suction hose).

Analyzing Pumping Plants Driven By Internal Combustion Engines

More comprehensive testing procedures are necessary to identify specific causes of low pumping plant efficiency when internal combustion engines are used because the engine efficiency must also be determined. In addition to the measurements discussed above, specialized equipment is needed to measure the actual power output of the engine. One such device, a dynamometer, allows the engine to be operated with a known load.

Strain gauges can be used to measure stress/strain deflection of the drive-shaft. This measurement can be converted to engine power output with a calibration curve. Once engine efficiency has been determined, the pump can be diagnosed in the same way as for electrically driven systems.

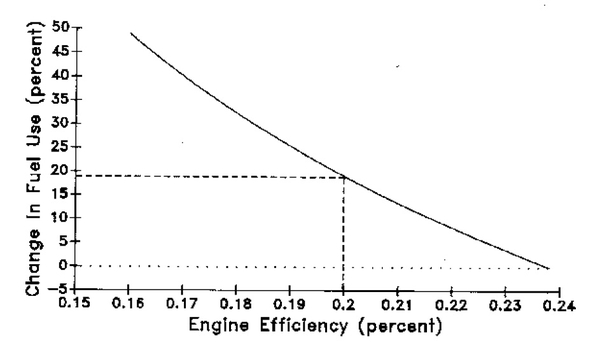

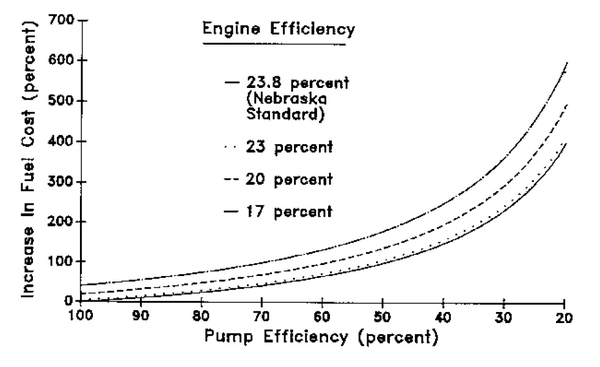

The importance of performing an engine analysis is demonstrated in Figure 9. For the gasoline engine shown, fuel consumption increases nearly 5 percent for each percentage decrease in engine efficiency. Poor engine efficiency combined with low pump efficiency quickly increases fuel costs (Figure 10).

You can measure the efficiency of your engine-driven pumping plant. If overall efficiency is low, contact a pump or engine dealer, consultant, or Extension Service agent who has the necessary engine analysis equipment.

In general, the lower the existing efficiency, the shorter the payback period for repair or replacement of system components. Higher fuel prices, increased operating pressure and pumping rate, and more annual operating hours shorten the payback period required to recover major repair or replacement costs.

Contact your local N.C. Cooperative Extension center for more information and assistance. Making a profitable decision about repairs and improvements requires a complete economic evaluation of existing performance and the cost of alternatives. Contact your personal accountant or an Extension economist before making costly repairs or replacing major components.

Publication date: June 1, 1996

Reviewed/Revised: Sept. 24, 2024

AG-452-6

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.