Trellis systems provide cane support for trailing semi-erect and erect cultivars to keep the fruit off the ground. Positioning canes on a trellis improves sunlight exposure, air movement, and spray penetration throughout the canopy. Using a trellis system will also make the planting easier to manage and harvest. Easier harvest results in cleaner picking, which reduces the presence of overripe or rotted fruit that attract June bugs and Japanese beetles. Trellising can also make floricane removal easier. It is best to construct trellises prior to the first harvest season.

Growers use a variety of trellis support systems to support canes. Each trellis type has advantages and disadvantages. It is not uncommon for growers to customize standard trellising designs to fit individual farm needs or to make use of available materials. Evaluate each trellis system to determine what type best suits your needs, including factors such as cost of materials and construction; availability of competent, trained labor; and climatic considerations, such as the potential for cold injury.

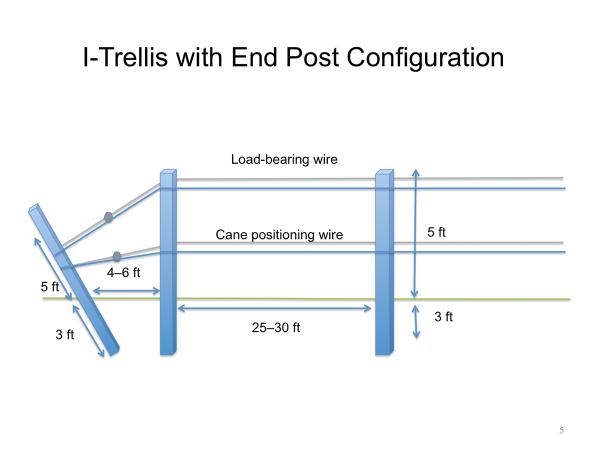

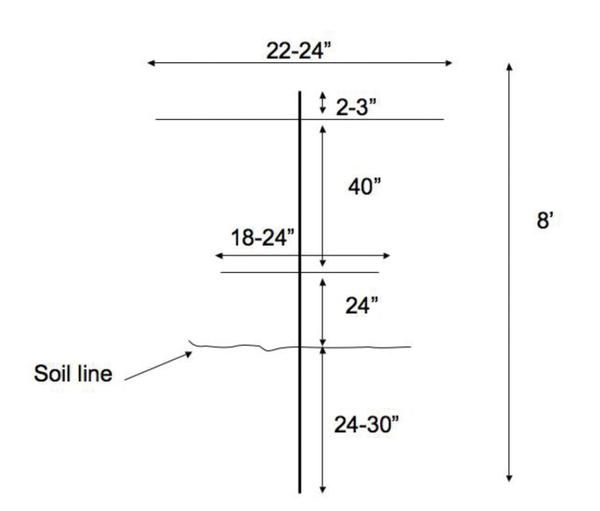

Common among most trellising systems are some basic components such as line posts, end posts, and wire. Line posts, made from either wood or metal, position wires at desired heights above the ground. Wood line posts stand up to stresses—such as wind— better than metal posts. Wood posts must be treated for in-ground use. Unless heavy metal posts are used for line posts, it is advantageous to use a wood line post every second to third post. Drive or set posts 2 ft into the ground with 5 ft remaining above ground. Wood posts should have a top diameter of about 4 in. For hand-harvested crops, set posts no more than 25 to 30 ft apart. The end posts, where wire tensioning is used, should be larger in diameter than the line posts. We suggest a minimum of 8 ft in length with a 6 in. top diameter to allow posts to be driven 3 ft into the ground. Generally, wood is used for end posts, with anchor posts to provide further support.

The top wire on the trellis is the load-bearing wire. Use a 121⁄2 gauge high tensile, fence wire. The lower wires are for cane positioning and do not need to be as heavy gauge. A 14-gauge high tensile wire should be adequate.

I-Trellis (Hedgerow)

The I-trellis can be a single load bearing wire, or two wires (load bearing and cane positioning) secured to posts at 2 and 4 ft above the ground (Figure 7-1). Posts can be metal or wood treated for in-ground use, and should be set at least 2 ft deep and spaced about 25 to 30 ft apart. Secure canes loosely to the wire or tuck them in between the two wires.

This trellis is relatively inexpensive and easy to build, although yields may be lower than with other trellis designs. The canopy can become crowded, which results in greater disease pressure, increased difficulty in harvesting, and potentially, lower fruit quality.

V-Trellis (with Metal T-Posts)

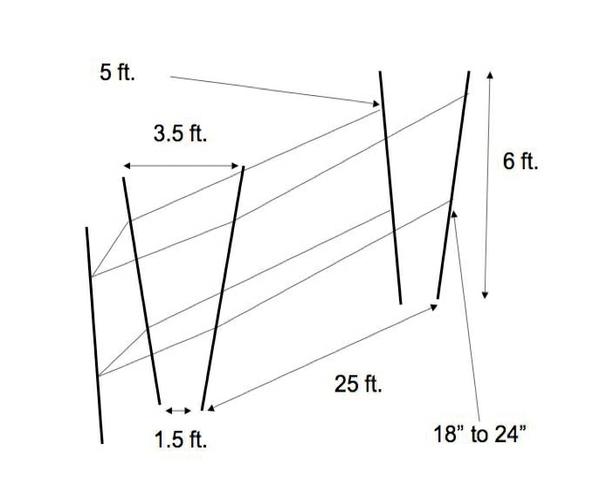

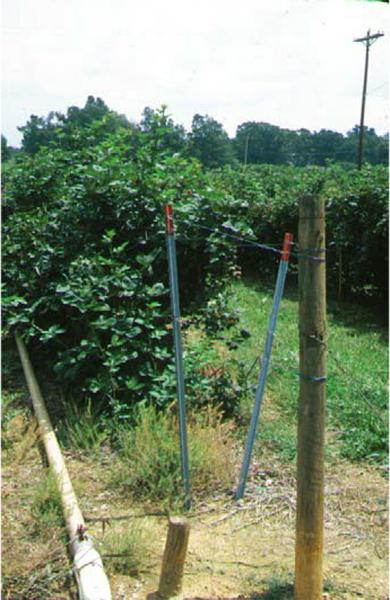

The most common type of caneberry trellis is the V-trellis (Figures 7-2a and 7-2b). The typical V-trellis design has steel posts that are set 20 to 30 degrees from vertical. The “V” shape allows for floricanes to be tied to the outside wires for ease of harvest and leaves space for the primocanes to grow in the middle. An advantage of the V-trellis is that the height of the wires can be easily repositioned depending on the cultivar’s requirements.

This trellis can be slightly more expensive, particularly compared to the T- trellis, because more posts are needed.

T-Trellis

This trellis functions similarly to the V-trellis, although it has a different configuration (Figures 7-3a and 7-3b). This trellis can be built with either t-post or pressure treated lumber. Set 8 ft posts, 2 ft into the ground. Use 2 in. by 4 in. pressure treated lumber for the cross-arms that support the wires. Set posts 20 to 30 ft apart in the row.

Moveable Trellises

There are several moveable trellis designs that include the shift trellis, rotating cross-arm (RCA), and those custom trellis built by growers.

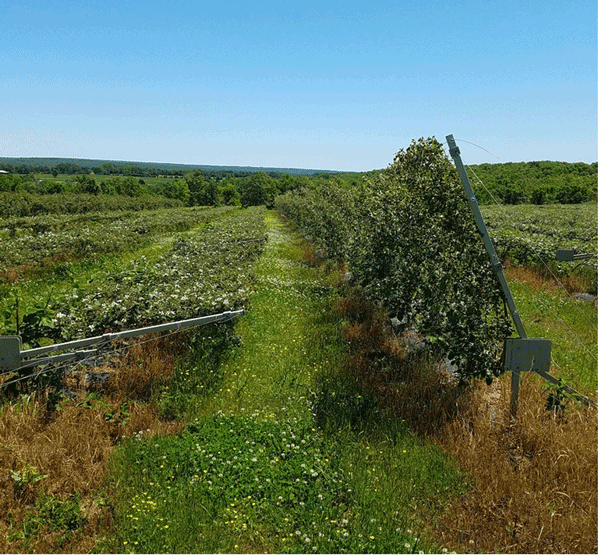

All movable trellis systems move the position of the canes based on the stage of the cropping cycle. In the early spring, the trellis is moved to a horizontal position (the 9 o’clock position on a clock) to force all shoots to emerge upward toward the sun. This positions the shoot growth on one side of the arm. Toward the end of flowering, the canopy is moved beyond the vertical position for harvest (the 2 o’clock position on a clock face). With all the shoots on one side of the trellis arm, the fruit will also develop on this side of the trellis. The trellis row can be oriented to position the fruit in the shade if the row is oriented east to west, and with the arm rotated toward the north during harvest. This reduces heat-related fruit quality problems and improves the speed and efficiency of the harvest. In general, this type of trellis system requires intense management of the primocanes. Scientists in Arkansas are developing new methods of training primocanes that reduce labor. The ability to lay the trellis and canes down in a horizontal position close to the ground provides the opportunity to put a row cover over the plants. This cover protects the canes during the winter and blooms in the spring from cold temperatures. Growers in Arkansas have been able to save their blackberry crops by covering plants with 1 oz covers during extreme freeze and frost events.

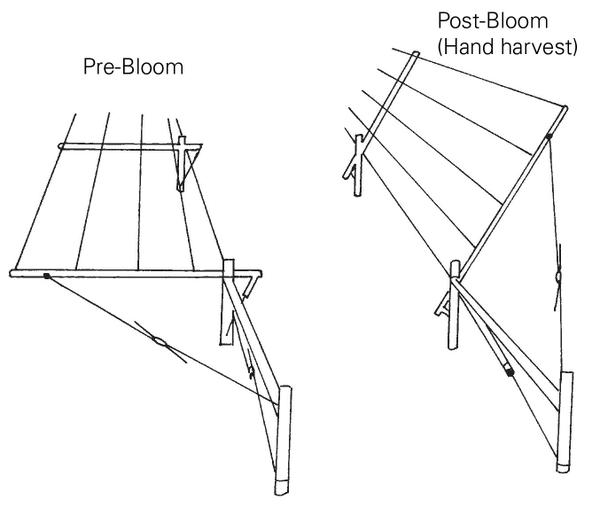

The shift trellis, developed by the late Herb Stiles at Virginia Tech, is made of wood and pivots in an arc from one side of the row to the other (Figures 7-4a and 7-4b). For more information, see Shift-Trellises for Better Management of Brambles (PDF, 1,123 KB).

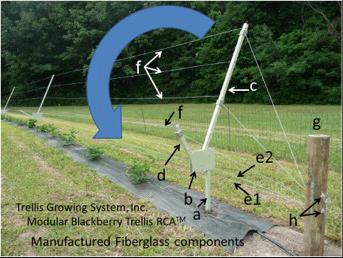

Commercial rotating cross-arm (RCA) trellises are constructed of fiberglass-reinforced plastic components manufactured by the pultrusion process. The trellis consists of a post (approximately 50 cm) (a) which has two plates (b) attached at the top (Figure 7-4c). A long (c) and a short (d) cross-arm are secured between the two plates. The position of the cross-arms can be changed by moving the placement of quick release pins There are two cane training wires (e1 and e2) that are threaded through holes in the plates. Additional trellis wires (f) are threaded through both cross-arms and secured to the end trellis assembly arms. The wires in the foreground are connected to a wooden tie-back post (g). The primocanes are placed on the training wire at the base of the short cross-arm (e1). Wires terminate at the wooden tie-back post and on end trellis assembly arms on the first and last posts of each row with a “Quik End” tensioner (h) which has internal spring-loaded clamps. In late summer or winter, the canes are attached to the training wire on the long cross-arm (e2). Figure 7-4d shows the long cross arm oriented horizontally (bloom position) and at the upright (harvest) positions. Notice that once in the "harvest" position (right) the fruit will be in the shade due to orienting the trellis row east and west with the fruit on the north side.

Growers have also fabricated their own moveable trellising systems with local materials and customization to their operation.

The University of Arkansas Extension is developing a publication on managing movable trellises. Check the Commercial Horticulture in Arkansas website for information.

| Trellis Type | Advantages | Disadvantages |

|---|---|---|

| I-Trellis |

|

|

| V-Trellis (with metal T-posts) |

|

|

| T-Trellis (with wood) |

|

|

| Shift Trellis and Rotating Cross-arm Trellis |

|

|

Publication date: Feb. 23, 2023

AG-697

Other Publications in Southeast Regional Caneberry Production Guide

- Introduction

- Cultivars

- Site Selection

- Site Preparation, Planting, and Establishment

- Plant Growth

- Pruning and Training

- Trellis Systems

- Tunnel Production

- Water Management

- Integrated Pest Management and Pollination

- Fertility Management

- Fruit Development

- Harvesting and Postharvest Management

- Food Safety Considerations for Caneberry Production

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.