For centuries, gardeners have used a wide variety of techniques for sheltering plants from cold weather—both in early spring and fall—to extend the growing season for a longer, larger harvest. Ambitious gardeners can harvest greens and other cool-weather crops all winter by providing the right conditions. Warm-season crops like tomatoes and cucumbers can get as much as a month’s head start in the spring or last a month longer in the fall than their conventionally planted counterparts. There are many ways to lengthen the growing season, depending on the amount of time and money invested.

A continuum of season extenders from simplest to most complex:

Cloches

Low tunnels and row covers

Cold frames and hot beds

High tunnels

Greenhouses

Cloches

The cloche was originally a bell-shaped glass jar set over delicate plants to protect them from the elements and help them get an early start in the spring or extend the fall garden as long as possible. The definition has expanded, however, to include many types of portable structures that shelter plants from drying winds and cold air. They trap solar radiation and keep moisture from evaporating from the soil and plants. Cloches are generally lightweight, portable, and reusable. A cloche can be a wax-paper cone, a water-filled plastic cylinder, or simply a cut-off plastic milk container (Figure E–1). It is preferable to have a design that can be closed completely at night to prevent frost damage, and opened or completely removed during the day for good air circulation. Cloches should be anchored or heavy enough that they do not blow away.

Figure E–1. Garden cloches made from cut plastic bottles protect plants from frost.

Mandy Prowse, Flickr CC BY-ND 4.0

Row Covers and Low Tunnels

Row covers and low tunnels employ a spun-bond polyester fabric or plastic laid over an entire row or rows of a crop and sealed along the edges to trap heat and block wind (Figure E–2). Covers and low tunnels are often used in conjunction with plastic mulch and drip irrigation. These two systems differ only in that the "tunnels" in the low tunnel system are created with the use of wire hoops pushed into the soil to hold up the fabric so it does not come in contact with plant foliage. Both of these methods can offer 4 – 5°F of frost protection and have the added benefits of screening out some damaging insects and diseases so that yields are not only earlier and larger, but often of better quality. Be aware that some insects may be trapped under the cover because they are already present in the soil or on the plants.

For those crops that are sensitive to heat or require pollination, care must be taken to remove these covers in a timely manner. Daytime opening is necessary for crops such as tomatoes and peppers if the temperature under the cover is expected to exceed 90°F for several hours. Under such conditions, the easiest way to ventilate quickly is to make long slits at the top of the low tunnel—but this should be done in anticipation of the high temperatures, not after the fact. Cucurbits (melons, cucumbers, and squash) are more tolerant of high temperatures.

Cold Frames and Hot Beds

Cold frames and hot beds are relatively inexpensive, simple structures that provide a favorable environment for growing cool-weather crops in early spring, fall, and into the winter months (Figure E–3). Some are elaborate and require a large investment, but most are reasonably priced for those who are serious about extending the season of fresh vegetables.

Cold frames rely on the sun as their sole source of heat. During the day the soil is heated by the sun; at night a cover can be used to slow the loss of heat. Hot beds supplement the heat from the sun with heating cables or with fresh manure buried beneath the rooting zones of the plants. The ideal location for a cold frame is a southern or southeastern exposure with a slight slope to ensure good drainage and maximum solar absorption. A sheltered spot with a wall or hedge to the north provides protection against winter winds. Sinking the frame into the ground also provides some protection and insulation. Some gardeners make their cold frames lightweight enough to be moved from one section of the garden to another.

In early spring a cold frame is useful for hardening seedlings that were started indoors or in a greenhouse. The cold frame provides a transition period for gradual adjustment to the outdoor weather. It is also possible to start cool-weather crops in the cold frame and either transplant them to the garden or grow them to maturity in the frame.

Use cold frames in spring and summer for plant propagation. Young seedlings of hardy and half-hardy annuals can be started in a frame many weeks before they can be started in the open. The soil in a portion of the bed can be replaced with media suitable for rooting cuttings, such as sand or peat moss.

Fall is also a good time for sowing some cool-weather crops in frames. If provided with adequate moisture and fertilization, most cool-season crops continue to grow through early winter in the protected environment of the cold frame. Depending on the harshness of the winter and whether additional heating is used, a frame may continue to provide fresh greens, herbs, and root crops throughout the cold winter months.

Cold frames can be built from a variety of materials. Wood and cinder block are the most common. If wood is used, choose a species that resists decay, such as a good grade of cedar. Never use wood treated with CCA, creosote, or pentachlorophenol, because these substances are harmful to growing plants. Wood frames are not difficult to build. Kits may also be purchased and easily assembled. Some kits even contain automatic ventilation equipment.

There is no standard-sized cold frame. The dimensions of the frame depend on the amount of available space, desired crops, and permanency of the structure. Do not make the structure too wide for weeding and harvesting; 4 to 5 feet is about as wide as is convenient to reach across.

Insulation may be necessary when a sudden cold snap is expected. A simple method is to throw burlap sacks filled with leaves, old blankets, or tarps over the frame at night to provide some protection and aid heat retention. Bales of straw or hay may also be stacked against the frame.

Ventilation is most critical in the late winter, early spring, and early fall on clear, sunny days. A thermometer in the cold frame can be used to monitor the daily maximum and minimum temperatures. On warm days, the sash should be raised partially to prevent the buildup of extreme temperatures inside the frame. Lower or replace the sash early enough each day to conserve some heat for the evening.

A few special precautions must be taken with cold frames and hot beds. In summer, extreme heat and intensive sunlight can damage plants. This damage can be avoided by shading with lath sashes or old bamboo window blinds. Also, the nearly airtight cold frame slows evaporation, so it is easy to overwater. To help reduce disease problems caused by overwatering, water early in the day so that plants dry before dark.

Convert a cold frame to a hot bed:

- Dig out an area 8 or 9 inches deep (deeper if gravel is added for increased drainage).

- Add an 18-inch layer of fresh horse manure.

- Cover with 6 inches of good soil.

High Tunnels

High tunnels are sometimes referred to as “hoop houses.” They are constructed of PVC or metal bows that are attached to metal posts that have been driven into the ground about 2 feet deep. The PVC or metal bows are covered with one to two layers of 6-mil greenhouse-grade polyethylene and allow a gardener to walk inside (Figure E–4). Tunnels are ventilated by manually rolling up the sides each morning and rolling them down in early evening. High tunnels are a nice compromise between unheated low tunnels and a heated greenhouse. They enhance plant growth, yield, and quality. Although they do provide some frost protection, their primary function is to elevate temperatures a few degrees each day over a period of several weeks.

Remember to remove covers!

For crops requiring bee pollination, the covers are removed about the time that the first female flowers appear. For primarily wind-pollinated crops (tomato, pepper, eggplant), removal of covers is based on temperature, with a goal that the temperature not exceed 90°F for more than a few hours when the flower buds begin to open.

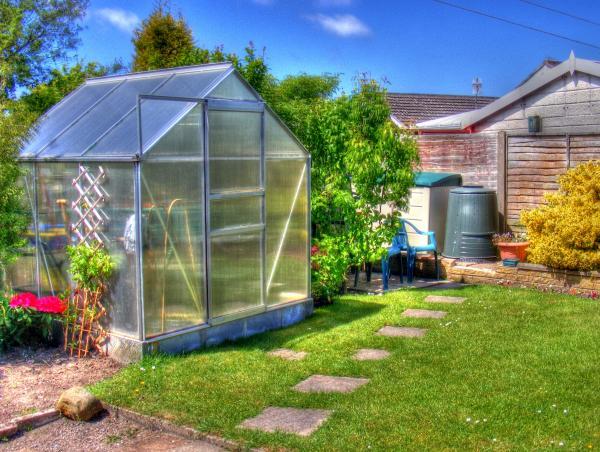

Greenhouses

Greenhouses can vary widely in design, durability, and cost. Location of the structure, whether it will be free-standing or attached to the home, and if it will be heated are important considerations. It can be a simple inexpensive PVC structure covered with plastic or an elaborate glass conservatory. Placing a greenhouse in a location with adequate sun exposure is extremely important. Delays in watering, or lack of adequate and timely heat, ventilation, or pest control, can lead to disappointing results. The more technology one invests in, the lower is the level of daily care that may be required. When deciding on the type of structure, be sure to plan for adequate bench space, storage space, and room for future expansion. Large greenhouses are easier to manage because temperatures in small greenhouses fluctuate more rapidly. In small greenhouses, the air volume inside is relatively small. So when the door is open, there can be a huge gain or loss of heat.

Lean-to. A lean-to greenhouse is a half greenhouse, split along the peak of the roof to lean against another structure, such as a house, shed, or garage (Figure E–5). A lean-to greenhouse is useful where space is limited to a width of approximately 7 to 12 feet and is the least expensive greenhouse structure. The disadvantages include some limitations on space, sunlight, ventilation, and temperature control.

Free-standing structures. Free-standing greenhouses are separate structures; they can be set apart from other buildings to get more sun and can be made as large or small as desired (Figure E–6).

Structural Materials

Many kinds of commercial greenhouse frames and framing materials are available. The frames are made of wood, galvanized steel, or aluminum. Build-it-yourself greenhouse plans are usually for structures with wood or metal pipe frames. Plastic pipe materials generally are inadequate to meet snow and wind load requirements. Greenhouse coverings include long-life glass, fiberglass, rigid double-wall plastics, and film plastics with one-year to three-year lifespans. All of these have advantages and disadvantages.

Glass. An aluminum frame with a glass covering provides a maintenance-free, weather-tight structure that minimizes heat costs and retains humidity. Tempered glass is frequently used because it is two or three times stronger than regular glass. Small prefabricated glass greenhouses are available for do-it yourself installation, but most should be built by the manufacturer because they can be difficult to construct. The disadvantages of glass are that it is easily broken, initially expensive to build with, and requires much better frame construction than fiberglass or plastic. A good foundation is required, and the frames must be strong and must fit well together to support heavy, rigid glass.

Fiberglass. Fiberglass is lightweight and strong. A good grade of fiberglass should be used because poor grades discolor and reduce light penetration. Use only clear, transparent, or translucent grades for greenhouse construction. Light penetration is initially as good as glass but can drop off considerably over time with poor grades of fiberglass.

Double-wall plastic. Rigid double-layer plastic sheets of acrylic or polycarbonate are separated by webs. They are durable and are usually coated by a UV-inhibitor to extend their life.

Film plastic. Film plastic coverings are available in several grades of quality and several different materials. Generally, these are replaced more frequently than other covers. Structural costs are very low because the frame can be lighter and plastic film is inexpensive. The films are made of polyethylene (PE), polyvinyl chloride (PVC), copolymers, and other materials. A utility grade of PE that lasts about a year is usually available at local hardware stores. Commercial greenhouse grade PE has ultraviolet inhibitors in it to protect against ultraviolet rays, and it lasts 12 to 18 months. Copolymers last two to three years.

Heating

The heating requirement of a greenhouse depends on the desired temperature for the plants grown, the location and construction of the greenhouse, and the structure’s total outside exposed area. The heating system must be adequate to maintain the desired day or night temperature.

Heating systems can be fueled by electricity, gas, oil, or wood. The heat can be distributed by forced hot air, radiant heat, hot water, or steam. For safety purposes and to prevent harmful gases from contacting plants, all gas, oil, and wood-burning systems must be properly vented to the outside. Unvented heaters (no chimney) using propane gas or kerosene are not recommended.

Air Circulation

Installing circulating fans in your greenhouse is a good investment. During the winter when the greenhouse is heated, you need to maintain air circulation so that the temperature remains uniform throughout the greenhouse. Without air-mixing fans, the warm air rises to the top and cool air settles around the plants on the floor.

Small fans with a cubic-foot-per-minute air-moving capacity equal to one-quarter of the air volume of the greenhouse are sufficient. For small greenhouses (less than 60 feet long), place the fans in diagonally opposite corners but out from the ends and sides. The goal is to develop a circular (oval) pattern of air movement. Operate the fans continuously during the winter. Turn these fans off during the summer when the greenhouse needs to be ventilated.

Ventilation

Ventilation is the exchange of inside air for outside air to control temperature, remove moisture, or replenish carbon dioxide (CO2). Natural ventilation uses roof vents on the ridge line with side inlet vents (louvers). Warm air rises on convective currents to escape through the top, drawing cool air in through the sides.

Mechanical ventilation uses an exhaust fan to move air out of one end of the greenhouse while outside air enters the other end through motorized inlet louvers. Exhaust fans should be sized to exchange the total volume of air in the greenhouse each minute.

Ventilation requirements vary with the weather and season. One must decide how much the greenhouse will be used. In summer, one to one-and-a-half air volume changes per minute are needed. Small greenhouses need the larger amount. In winter, 20% to 30% of one air volume exchange per minute is sufficient for mixing in cool air without chilling the plants.

Cooling

Air movement by ventilation alone may not be adequate in midsummer; the air temperature may need to be lowered with evaporative cooling. Also, the light intensity may be too great for the plants, so shade cloth or paint may be necessary. Shade materials include roll-up screens of wood or aluminum, vinyl netting, and paint.

Controllers and Automation

Automatic control is essential to maintain a reasonable environment in the greenhouse. On a winter day with varying amounts of sunlight and clouds, the temperature can fluctuate greatly; close supervision would be required if a manual ventilation system were in use.

Thermostats can be used to control individual units, or a central controller with one temperature sensor can be used. In either case, the sensor or sensors should be shaded from the sun, located about plant height away from the walkway, and have constant airflow over them.

Water Systems

A water supply is essential. Hand watering is acceptable for most greenhouse crops if someone is available when the task needs to be done, but many hobbyists travel. A variety of automatic watering systems are available to help do the task over short periods of time. Timers or mechanical evaporation sensors can be used to control automatic watering systems.

Other Resources

Season Extension: Introduction and Basic Principles by Debbie Roos and Doug Jones

Publication date: Feb. 1, 2022

AG-831

Other Publications in North Carolina Extension Gardener Handbook

- 1. Soils & Plant Nutrients

- 2. Composting

- 3. Botany

- 4. Insects

- 5. Diseases and Disorders

- 6. Weeds

- 7. Diagnostics

- 8. Integrated Pest Management (IPM)

- 9. Lawns

- 10. Herbaceous Ornamentals

- 11. Woody Ornamentals

- 12. Native Plants

- 13. Propagation

- 14. Small Fruits

- 15. Tree Fruit and Nuts

- 16. Vegetable Gardening

- 17. Organic Gardening

- 18. Plants Grown in Containers

- 19. Landscape Design

- 20. Wildlife

- 21. Youth, Community, and Therapeutic Gardening

- Appendix A. Garden Journaling

- Appendix B. Pesticides and Pesticide Safety

- Appendix C. Diagnostic Tables

- Appendix D. Garden Tools

- Appendix E. Season Extenders and Greenhouses

- Appendix F. History of Landscape Design

- Appendix G. Permaculture Design

- Appendix H. Community Gardening Resources

- Appendix I. More NC State Resources

- Glossary

N.C. Cooperative Extension prohibits discrimination and harassment regardless of age, color, disability, family and marital status, gender identity, national origin, political beliefs, race, religion, sex (including pregnancy), sexual orientation and veteran status.